Digital guide

You are here:

- Home

- Other brands

- Vibro-meter 200-560-000-113 200-560-101-017

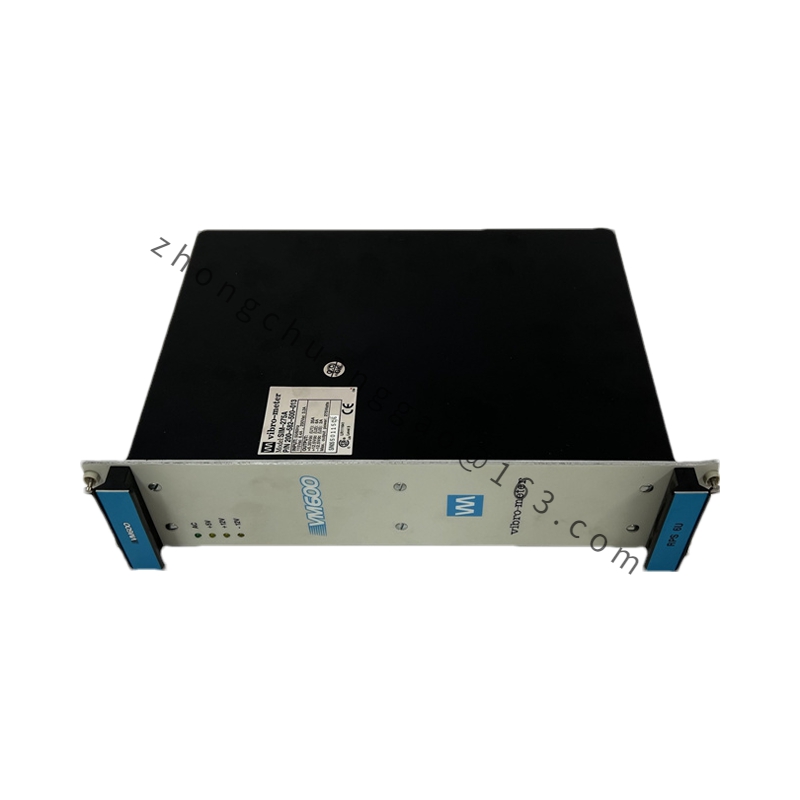

Vibro-meter 200-560-000-113 200-560-101-017

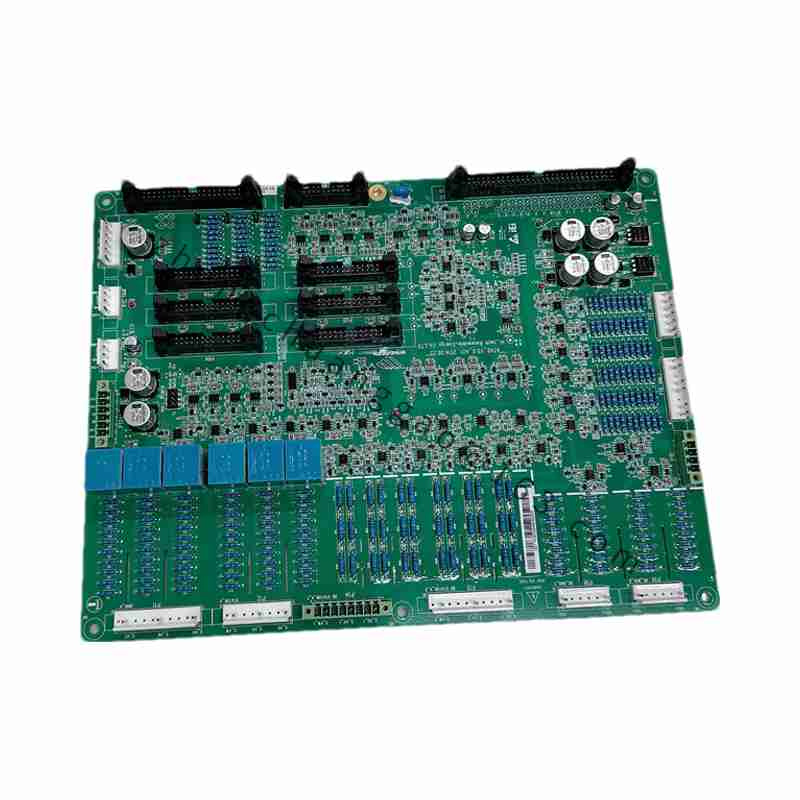

The Vibro-meter 200-560-000-113 200-560-101-017, also known as VM600 IOC4T, is an input/output controller module designed for vibration monitoring and control systems. It serves as a signal interface for MPC4 machinery protection cards within the VM600 series.

Detailed content

Technical Specifications:

- Relay Terminal Block: Capable of inserting 6-amp relay terminal blocks.

- Voltage Range: Operates within a voltage range of 12VDC to 110VDC and 120VAC to 230VAC.

- Programming Simplification: Utilizes IP frames to simplify processes into programmable blocks with blank parameters.

- IP Instructions: Offers over 60 IP instructions supporting memory, discrete and analog assistance, mathematics, communication, and high-speed counters.

- Compatibility: Compatible with direct logic CPUs such as dl05, dl06, d2-250-1, d2-260, and d4-450.

- Relay Specifications:

- Relay Name: RL1 to RL4

- Type: PE014005

- Contact Arrangement: 1 x NC or 1 x NO contact per relay (user-configurable)

- Rated Voltage: 250 VAC

- Rated Current: 5 AAC

Functional Characteristics:

- Vibration Data Collection: Able to collect data from vibration sensors or accelerometers.

- Data Processing: Capable of analyzing vibration data, calculating vibration frequency spectrum and amplitude.

- Alarm and Alert: Can set alarm thresholds to emit alerts when vibration exceeds safe ranges.

- Remote Communication: Supports communication interfaces like Ethernet or wireless for remote data transmission.

- Programmability: Offers customizable configuration and control according to application requirements.

- Real-Time Monitoring: Provides real-time vibration monitoring and data feedback.

- Recording and Storage: Capable of recording and storing vibration data for subsequent analysis.

- EMI Protection: Provides EMI protection for all inputs and outputs.

Application Scenarios:

Primarily used in vibration monitoring and control systems within industrial settings, such as machinery health monitoring, predictive maintenance, and fault detection.