Detailed content

Technical Specifications

| Specification | Description |

|---|---|

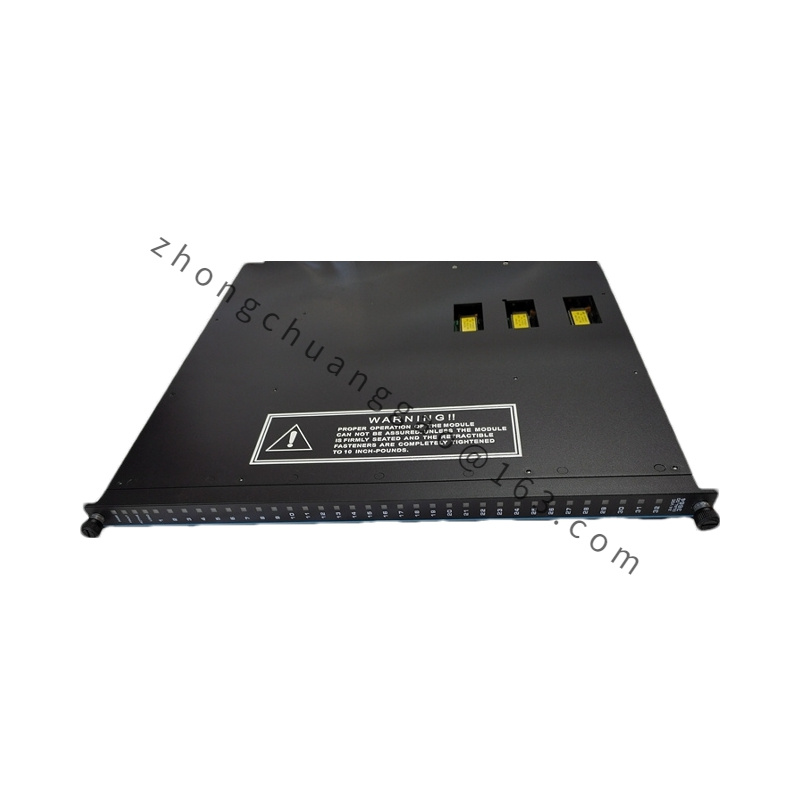

| Model Number | 9853-610 |

| Type | Analog Input Terminal Board / Pulse Input Terminal Board (depending on configuration) |

| Input Channels | 8 (for analog input) |

| Input Type (Analog) | Voltage Input (-10 V to +10 V), Current Input (0 mA to 20 mA) |

| Resolution (Analog) | 16-bit |

| Sampling Rate (Analog) | 1000 Hz |

| Power Supply | 24 V DC |

| Power Consumption | 5W |

| Protection Rating | IP65 |

| Physical Dimensions | 115 mm x 65 mm x 30 mm (4.5″ x 2.6″ x 1.2″) |

Note: Technical specifications may vary depending on the specific configuration and version of the 9853-610.

Functional Characteristics

- Precision and Accuracy: Designed to accurately capture and convert analog or pulse signals into digital form for processing and control.

- High Sampling Rate: Enables real-time monitoring and control by capturing signals at a high sampling rate (up to 1000 Hz for analog input).

- Multiple Input Channels: Offers multiple input channels (8 for analog input), allowing simultaneous monitoring of multiple signals.

- Robust Communication Interface: Equipped with communication interfaces for seamless integration with other system components and external devices.

- High-Level Protection: IP65 rating ensures protection against dust and water ingress, making it suitable for harsh industrial environments.

- Programmability: Users can define the behavior and functionality of each channel using specific programming software or configuration tools.

- Fault Diagnosis: Some versions may include fault diagnosis features to detect and report signal issues or hardware faults.

- Compliance with Industrial Standards: Meets industry standards for reliability, safety, and performance in industrial applications.

Application Scenarios

The Triconex 9853-610 is ideal for a wide range of industrial applications where precision and reliability are crucial. Some of its primary application areas include:

- Industrial Safety: Utilized in safety instrumented systems (SIS) to monitor critical process parameters and ensure safe operations.

- Process Control: Deployed in process industries such as chemicals, petrochemicals, and pharmaceuticals to control and optimize production processes.

- Power Generation: Essential in power plants for monitoring and controlling equipment performance and ensuring efficient energy generation.

- Oil and Gas: Applied in upstream and downstream operations to monitor flow rates, pressures, and other critical parameters.

- Transportation: Utilized in transportation systems, including railways and airports, for monitoring and controlling infrastructure components.