Detailed content

Technical Specifications

| Specification | Description |

|---|---|

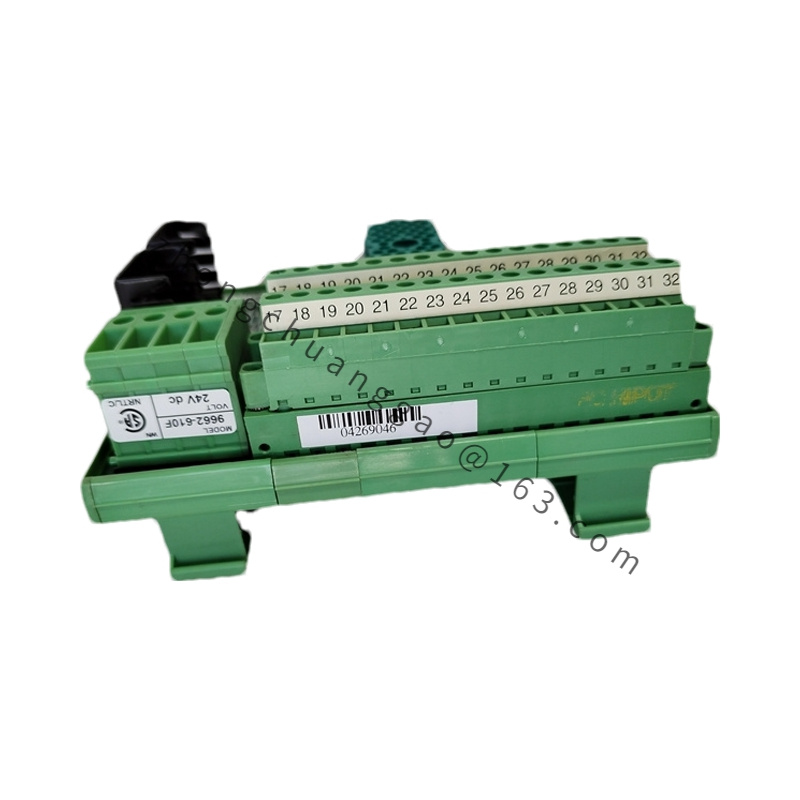

| Model | 9662-610 |

| Safety Design | High safety design meeting industrial automation safety requirements |

| Operating Voltage | 24Vdc/120Vac, adaptable to different power environments |

| Operating Frequency | 50/60Hz, compliant with international standards |

| Temperature Range | -40°C to +85°C (operating), -40°C to +70°C (storage) |

| Communication Interfaces | Ethernet, Modbus, TCP/IP, OPC |

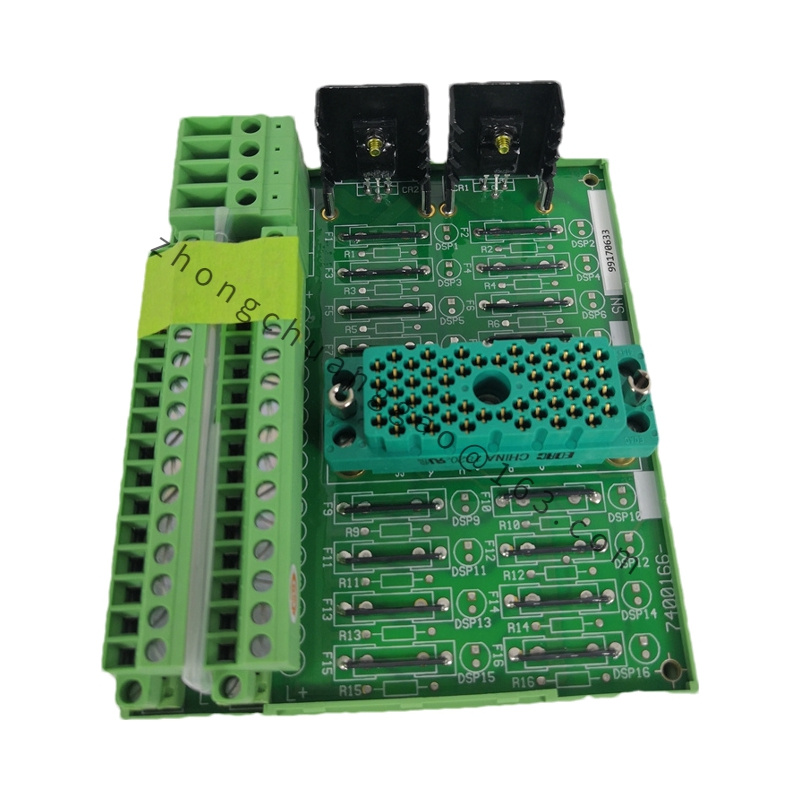

| I/O Points | 16 digital inputs, 16 digital outputs |

| Warranty | One-year warranty service |

Functional Characteristics

- High Safety and Reliability: The 9662-610 is designed with safety in mind, ensuring stable and reliable digital output functionality for various systems.

- Powerful Security Monitoring: It possesses strong security monitoring capabilities, protecting systems from potential threats.

- SIS Support: Supports Safety Instrumented System (SIS) operation, ensuring stable and safe equipment operation in industrial automation environments.

- Flexible Configuration: Offers flexible configuration options, allowing users to customize each digital output channel’s function and parameters to meet diverse application needs.

- Real-time Control: Capable of responding to control signals from the Triconex system in real-time, enabling precise control and monitoring of external devices.

- Easy Installation and Maintenance: Designed for ease of installation and maintenance, simplifying system maintenance and management tasks.

Application Scenarios

The Triconex 9662-610 digital output terminal module is widely applied in various industries where high reliability and safety are paramount. Some of its primary application areas include:

- Numerical Control Machinery: Used to control and monitor the operation of complex numerical control machines, ensuring precision and efficiency.

- Metallurgy: In metallurgical processes, it aids in controlling furnaces, melting equipment, and other critical machinery.

- Oil and Gas: Essential in the operation of oil and gas extraction, refining, and transportation systems, ensuring safe and efficient operations.

- Power Generation: Utilized in power plants to control and monitor various components of the power generation process.

- Manufacturing: In manufacturing environments, it controls production lines, robotic arms, and other automated equipment.

.jpg)