Detailed content

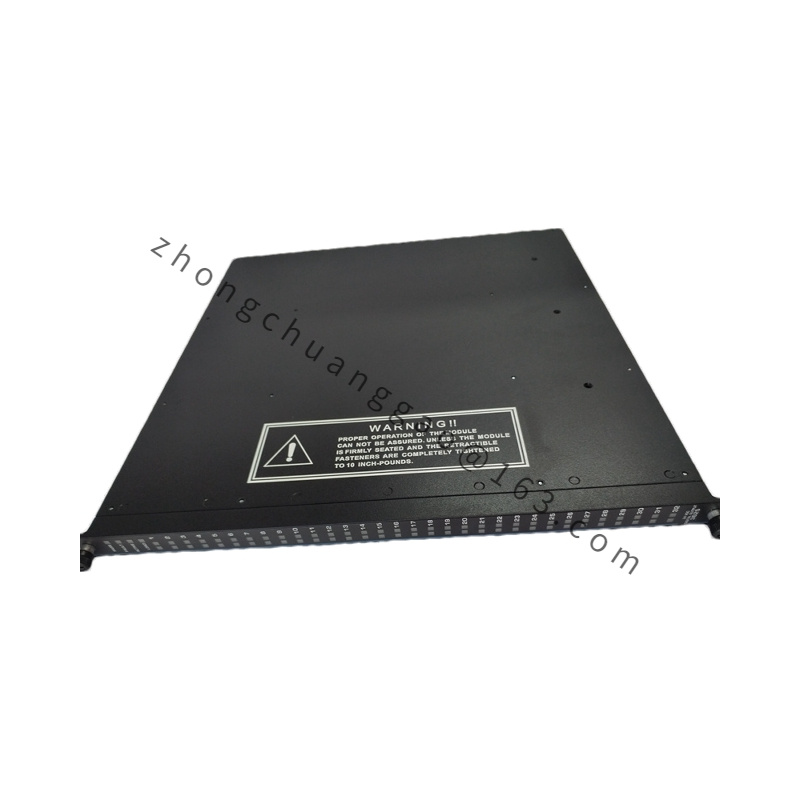

Technical Specifications

- Input Power: Nominally 24V DC, with an operating voltage range of 18V DC to 30V DC.

- Operating Temperature Range: From -40°C to +70°C, ensuring reliable performance in a wide range of environmental conditions.

- Storage Temperature Range: From -40°C to +85°C, allowing for safe storage in extreme temperatures.

- Humidity Adaptability: Operates within a humidity range of 5% to 95% RH (non-condensing), demonstrating excellent resilience against moisture.

- Weight: Approximately 1 kg (2.2 pounds), making it suitable for a range of industrial installations.

Functional Characteristics

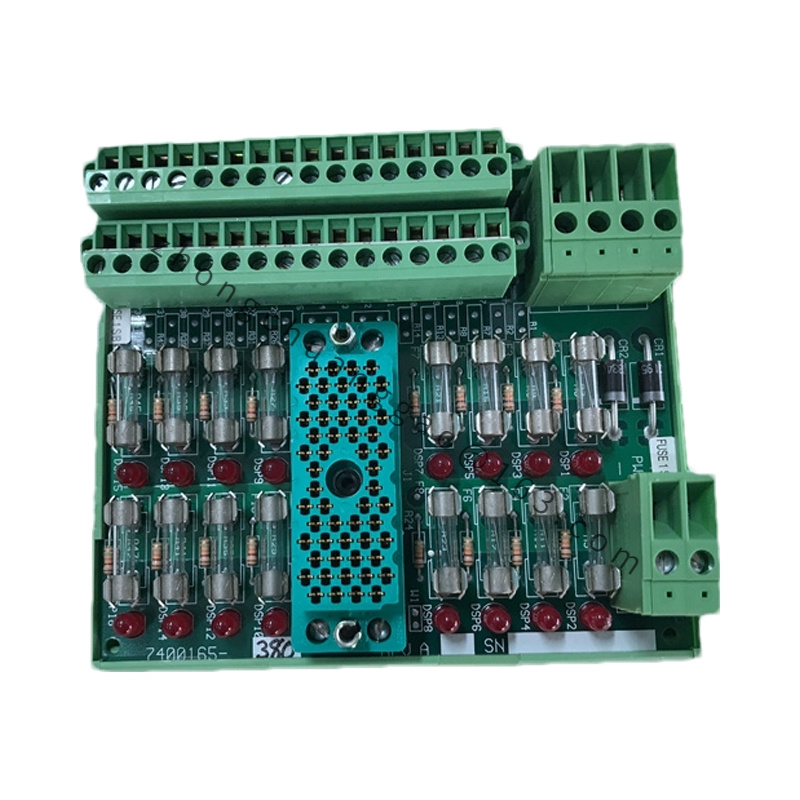

- Switch Input Capability: The 9563-810 is designed to connect with switches or discrete sensors, enabling the monitoring and acquisition of digital signals.

- Multiple Input Channels: It typically features multiple input channels, allowing for the connection of multiple switches or sensors simultaneously.

- Communication Interface: Equipped with a communication interface, facilitating the transmission of collected data to the main control system or other devices for monitoring, control, or data analysis.

- Industrial Standards Compliance: Compliant with industrial standards, ensuring reliability and stability in industrial environments, including resistance to interference, protection, and durability.

- Safety Features: Incorporates safety functions to ensure accurate signal acquisition and transmission, as well as safe system operation.

- Fault Diagnosis: Capable of detecting and reporting signal issues or hardware faults, enabling timely maintenance measures.

- Real-time Response: Provides rapid response to input signals, ensuring timely transmission to the main control system for real-time monitoring and control.

- Configurable and Programmable: Allows users to define the functionality and behavior of each channel using specific programming software or configuration tools, catering to specific application requirements.

Application Scenarios

The Triconex 9563-810 is widely used in various industrial sectors, including but not limited to:

- Oil and Gas Production: Monitors and controls equipment safety performance, helping to prevent hazards such as fires and explosions.

- Power Industry: Utilized in monitoring power equipment, controlling power systems, and executing power protection functions.

- Manufacturing: Enhances safety monitoring and control of mechanical equipment, preventing accidents and damages.

- Transportation: Assists in monitoring and controlling various transportation systems for smooth and safe operations.

- Nuclear Industry: Contributes to ensuring the safety and reliability of nuclear power plants and related systems.

- Aerospace: Supports critical safety and control functions in aerospace applications.

- Medical Equipment: Ensures accurate monitoring and control of medical devices and systems.