Detailed content

Technical Specifications

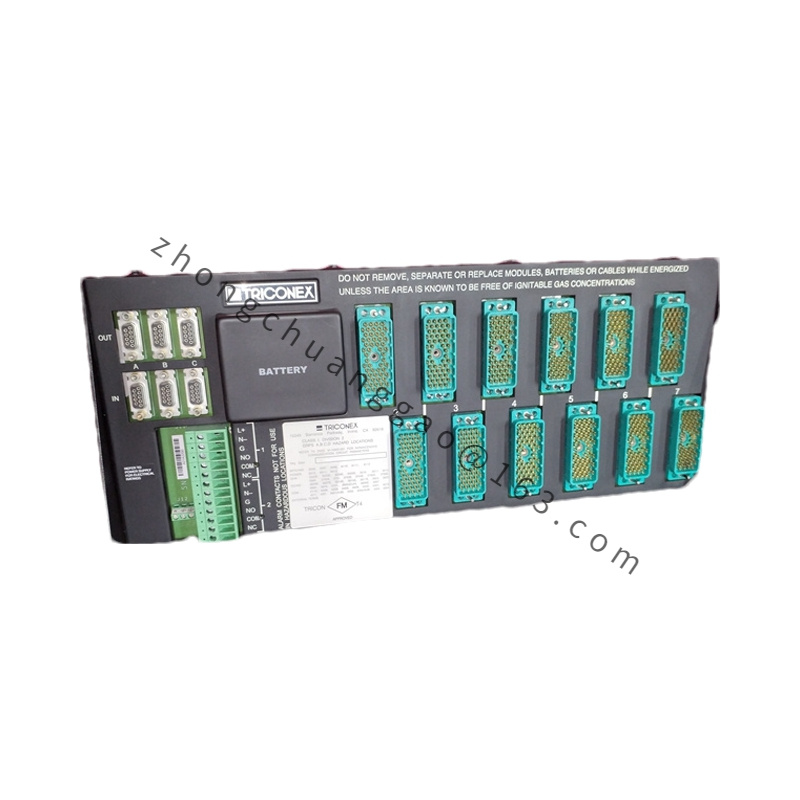

Type: Integrated DCS (Distributed Control System) Controller with PLC (Programmable Logic Controller) and Robot Controller capabilities.

Input Voltage Range: 10.5-30 Volts (RMS)

Output Voltage Range: 0-10 Volts (RMS)

Maximum Output Current: 24 Amperes

Maximum Frequency: 2500 Hz

Accuracy: ±1%

Communication Standards: Supports various communication protocols including DEICENET, PRFIBUS, CANBOST, and MODBUS, as well as wireless communication.

Fiber Network Capabilities: Capable of forming multiple fiber networks with features like logical independent dual bus electrical interfaces, dual fiber ring network redundancy, and automatic network reconstruction in case of failures.

Functional Characteristics

Integrated Design: Combines the flexibility of ABB’s AC500 PLC and IRC5 Robot Controller, eliminating the need for separate PLC cabinets, reducing costs and installation time.

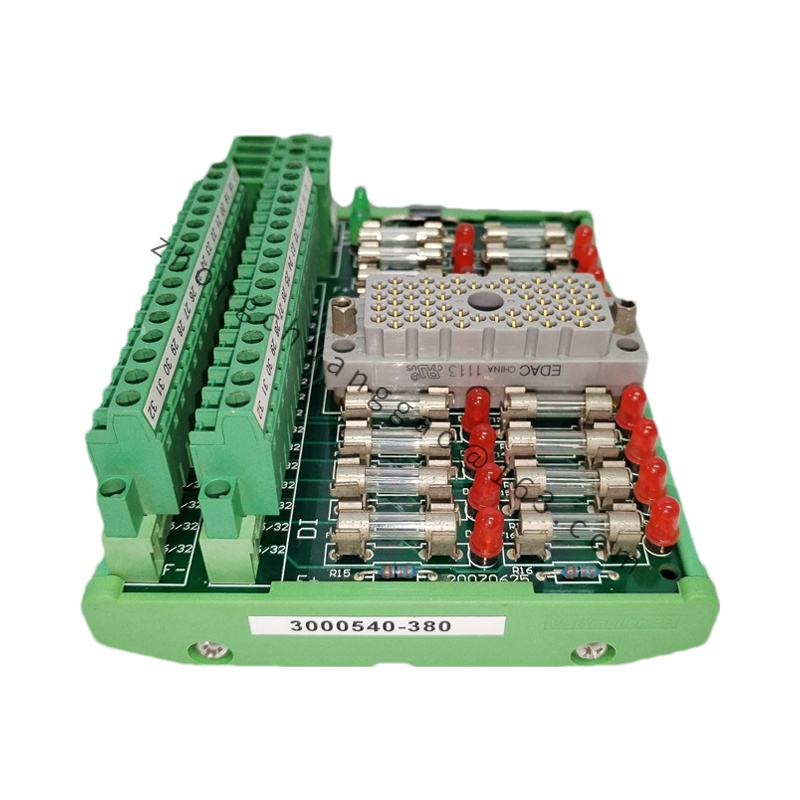

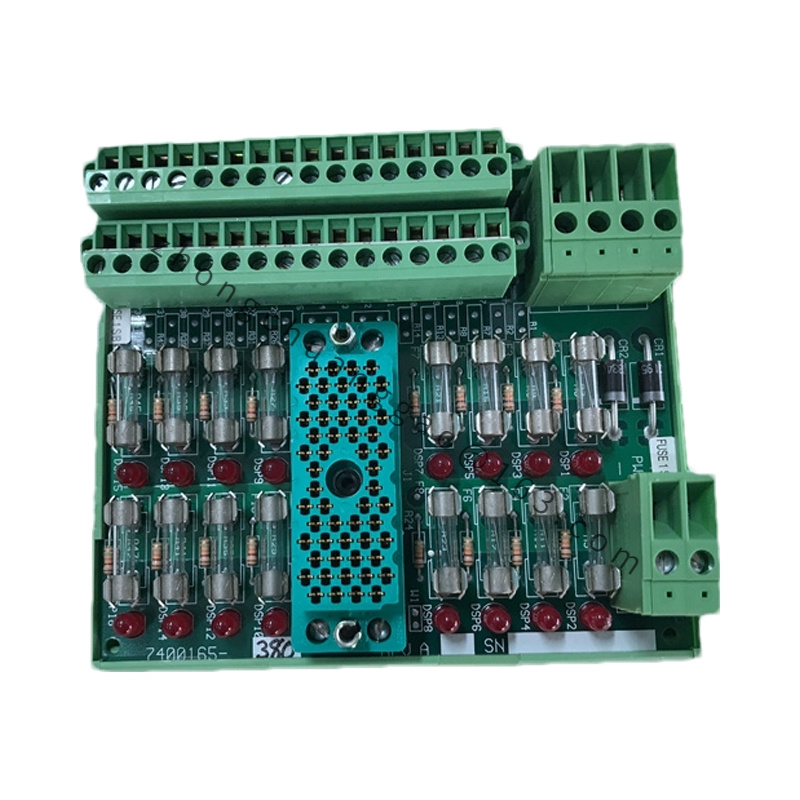

Multiple I/O Interfaces: Equipped with up to three local I/O boards and remote I/O bus communication, providing a single control point for various production unit functions.

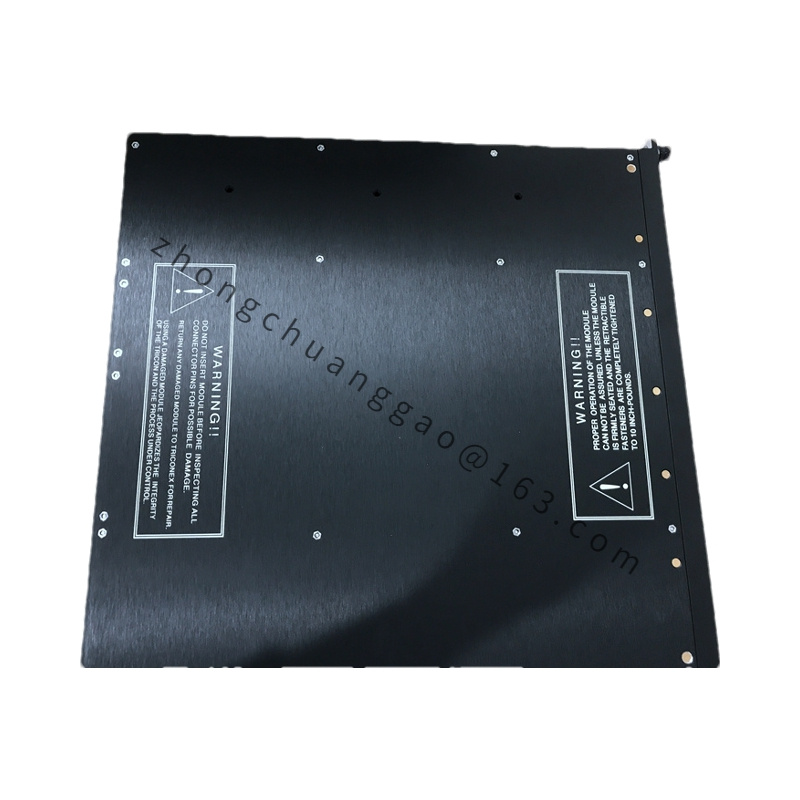

High Reliability: Designed with triple redundancy for critical industrial control applications, ensuring high stability and continuous operation.

Easy Configuration and Maintenance: The system is user-friendly, with intuitive setup and maintenance procedures, making it suitable for a wide range of users.

Advanced Networking: Supports high-speed communication rates up to 12 MBit/s and features such as automatic rate recognition and switch settings.

Application Scenarios

Robotic Cell Applications: TRICONEX 8110 is ideal for controlling and managing robotic cells, providing seamless integration between PLCs and robot controllers.

Complex Industrial Processes: Its high-precision control and wide range of communication protocols make it suitable for various industrial processes requiring high reliability and accuracy.

Automation and Manufacturing: Widely used in automation systems and manufacturing lines, enabling efficient control and monitoring of production processes.