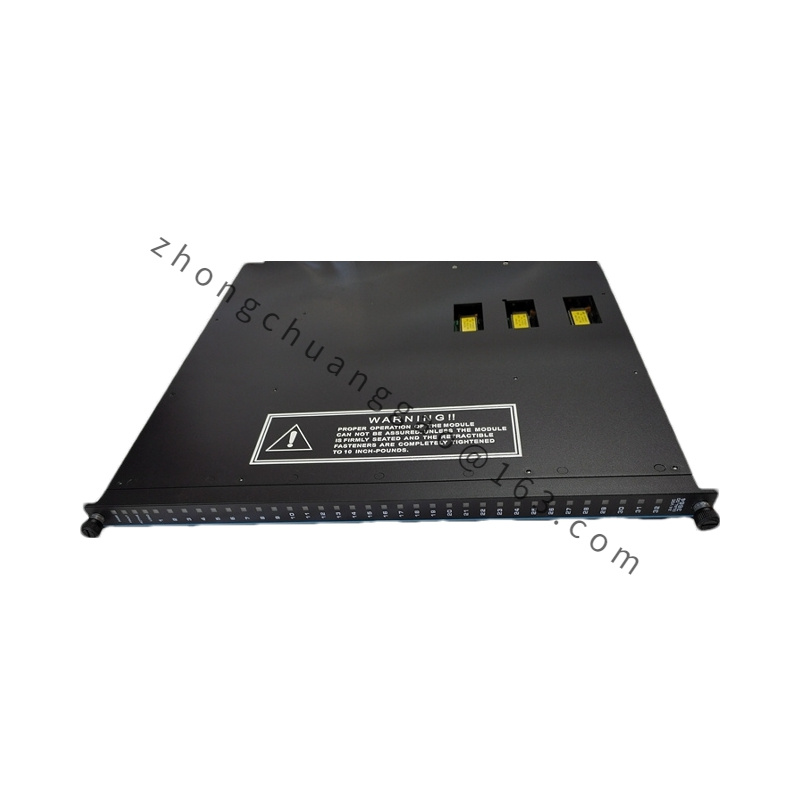

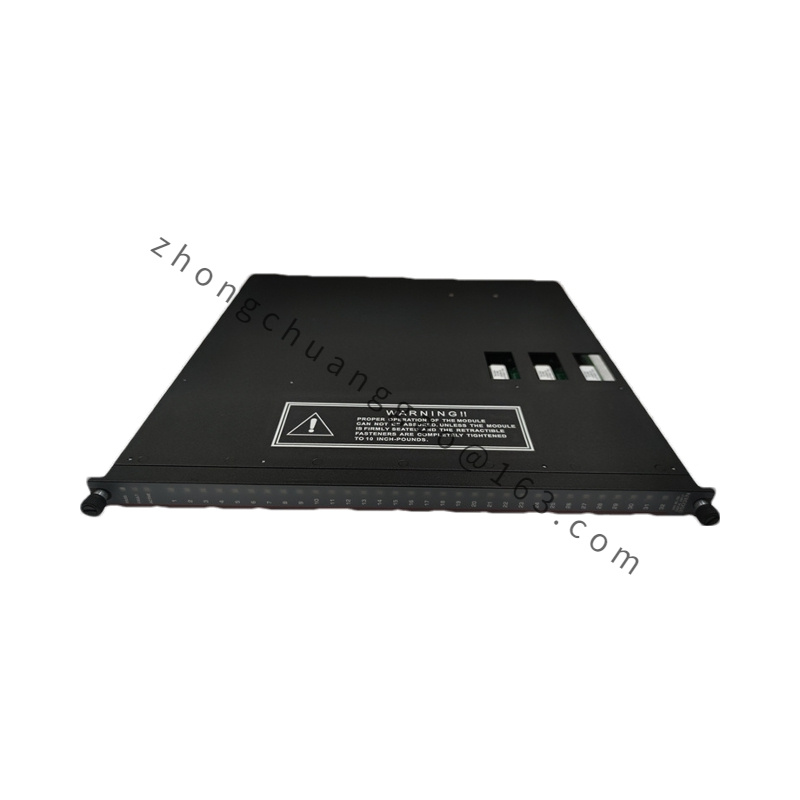

Triconex 3664

Technical Specifications:

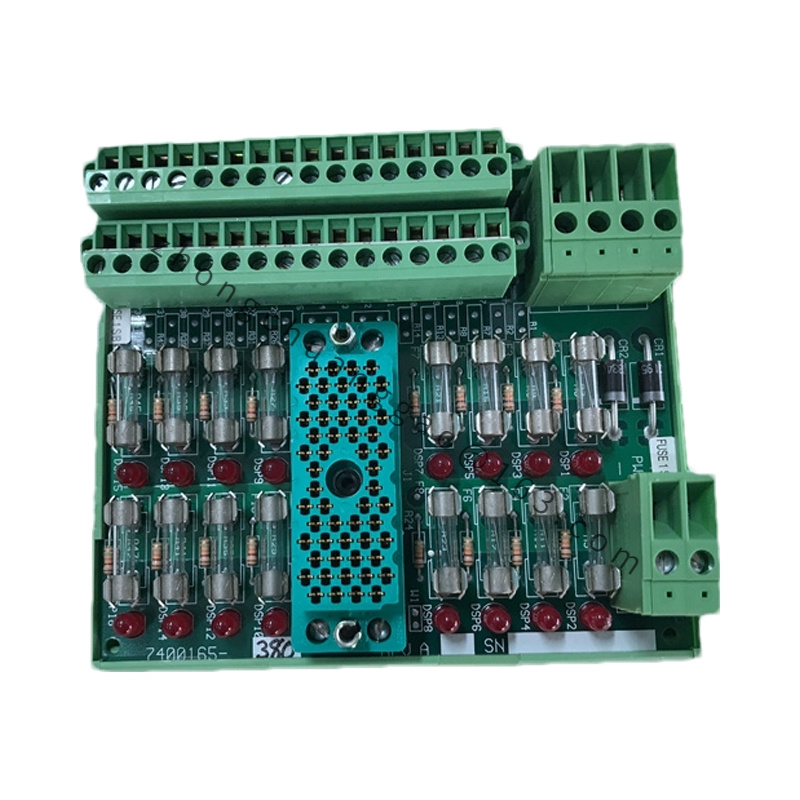

Input Channels: Multiple input channels for connecting sensors, switches, or other digital signal sources. Each channel is usually configurable independently.

Input Type: Supports digital input signals, typically used to monitor the status of digital switches (e.g., on/off, high/low).

Signal Types Supported: Includes digital switch states, pulse signals, and potentially other types of digital signals.

Detailed content

Sampling Rate: Some modules have fast sampling rates to monitor real-time changes in the state of digital input signals.

Communication Interface: May be equipped with a communication interface to transmit input data to the control system or other devices.

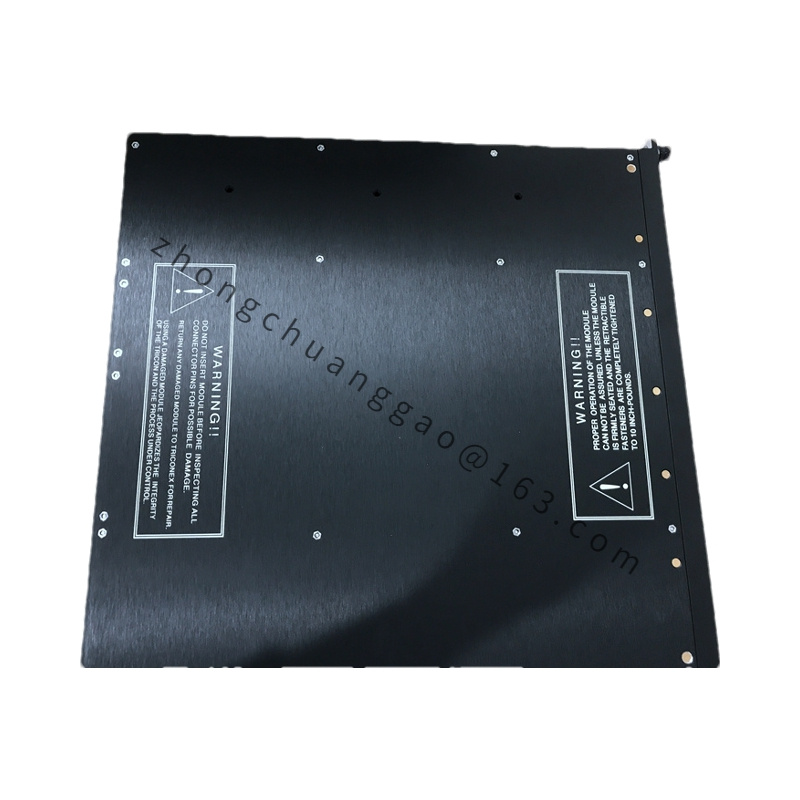

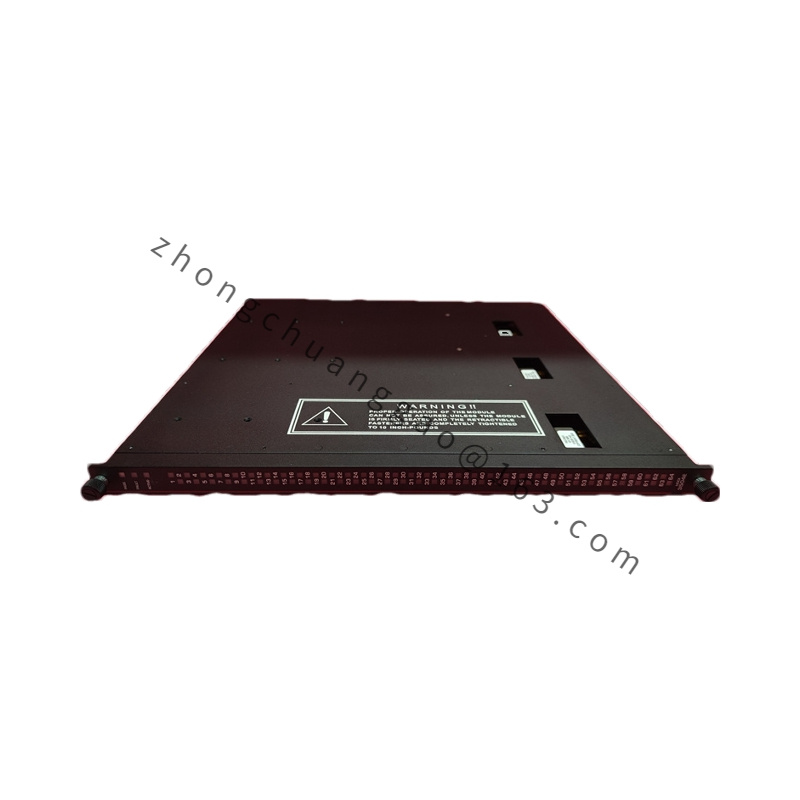

Protection Level: May have an appropriate level of protection to safeguard the module from dust, moisture, or other physical factors in the environment.

Compliance: Usually complies with industrial standards such as IEC 61131-2, ensuring reliability and interoperability.

Functional Characteristics:

High Reliability: Designed for stable operation in harsh industrial environments, ensuring long-term performance.

Fast Response: Capable of real-time monitoring and acquisition of input signals, with swift reaction times in control systems.

High Precision: Accurate signal acquisition capability, enabling precise measurement and recording of input signal values.

Flexible Configuration and Programming: Allows customization and adjustment based on specific application requirements, enabling flexible input signal processing and logical control.

Monitoring and Diagnostic Functions: Provides monitoring of module status, fault diagnosis, and alarms, enhancing system reliability and maintenance efficiency.

Self-Diagnostic Function: May have the ability to monitor the status and performance of the module, generating alerts or notifications when necessary.

Application Scenarios:

Industrial Automation: Widely used in various industrial automation systems, including oil and gas, chemicals, power generation, manufacturing, and process industries.

Control Systems: Integral part of control systems, monitoring and controlling process parameters, equipment states, and safety-critical functions.

Safety Instrumented Systems (SIS): Employed in safety systems to ensure compliance with safety standards and regulations, minimizing the risk of accidents and downtime.

Monitoring and Control: Used for monitoring digital switch states, pulse signals, and other critical process variables, enabling timely intervention and control.