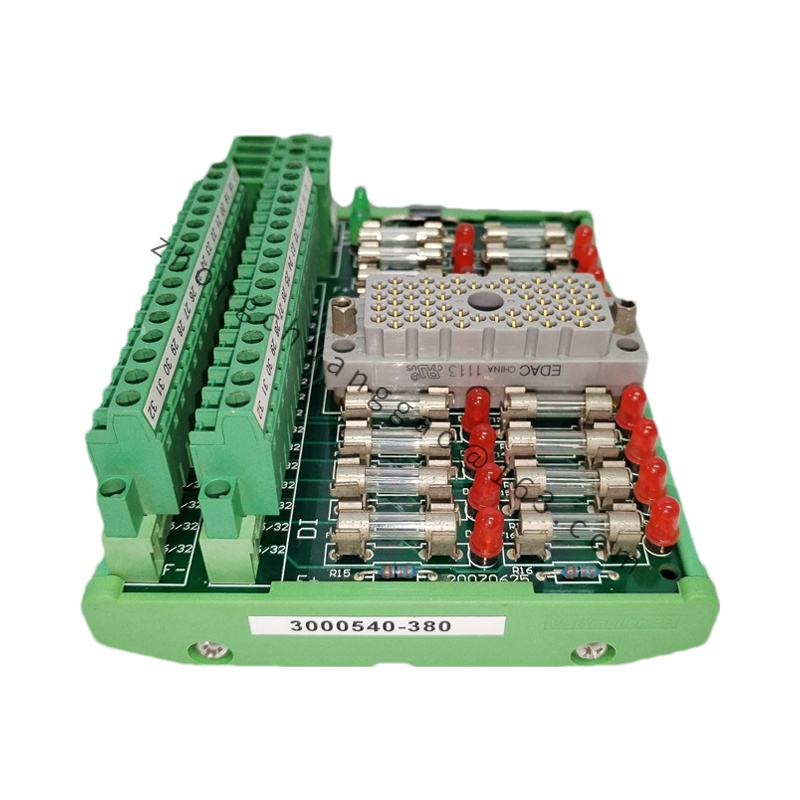

Detailed content

Technical Specifications

Analog Output Capability:

Provides high-precision analog output signals.

Signal type: 0-20 mA, 12-bit resolution.

Multi-channel output for controlling multiple external devices or actuators.

Digital I/O:

8 points of switching input and 8 points of switching output.

Programming and Customization:

Supports specific programming languages or tools for user configuration and customization.

Ladder diagram programming interface available for connection to computers or HMI (Human-Machine Interface).

Communication Interfaces:

Equipped with computer communication interfaces for integration with other systems, such as asphalt mixers.

Display and Control:

One-button start and stop, with manual and automatic control modes.

Display includes current temperature, throttle opening, target value, and fault diagnosis.

Temperature Control:

Maintains temperature within ±3°C of the target value.

Includes over-temperature alarm protection with user-settable alarm temperatures.

Functional Characteristics

High Reliability:

Utilizes high-quality components and materials, undergoing rigorous quality control and durability testing.

Capable of operating in harsh industrial environments with anti-interference and anti-vibration capabilities.

Multi-Channel Output:

Allows simultaneous control of multiple external devices or actuators, enhancing system flexibility and scalability.

Programmable Features:

Users can configure and customize the controller according to specific control strategies and industrial environments.

Integrated Design:

Seamlessly integrates with various industrial equipment and systems, reducing overall system complexity and cost.

Easy Operation and Maintenance:

Features a user-friendly HMI and easy-to-use software, lowering operational difficulty and maintenance costs.

Application Scenarios

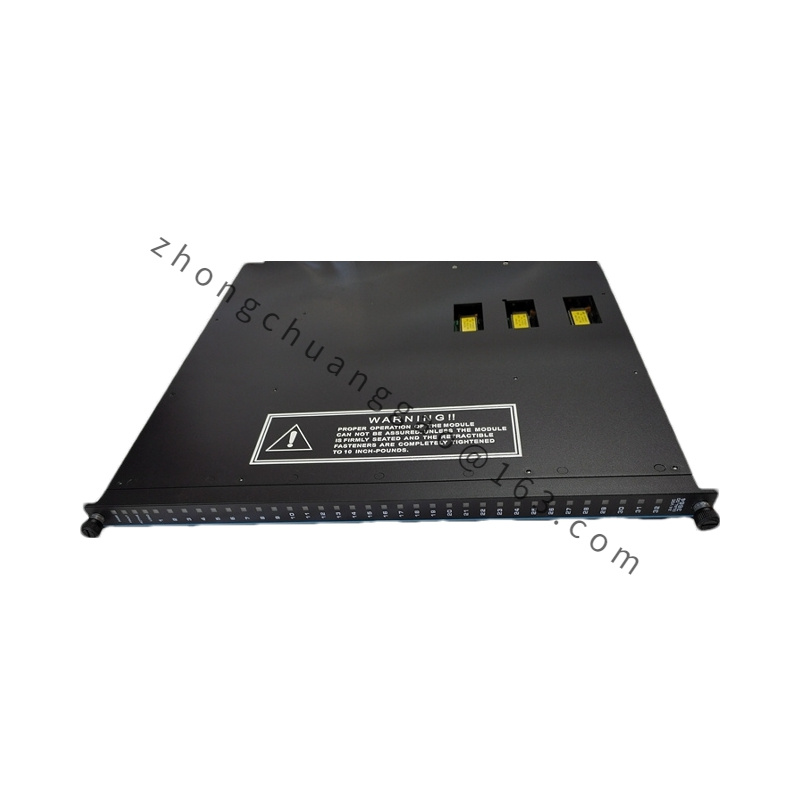

The Triconex 3481 controller is widely used in various industrial automation and safety systems, including but not limited to:

Industrial Safety Systems:

Monitors and controls critical industrial processes to ensure safety, responding to emergencies such as fires, leaks, and overheating.

May be integrated with emergency shutdown systems for rapid process shutdown in case of emergencies.

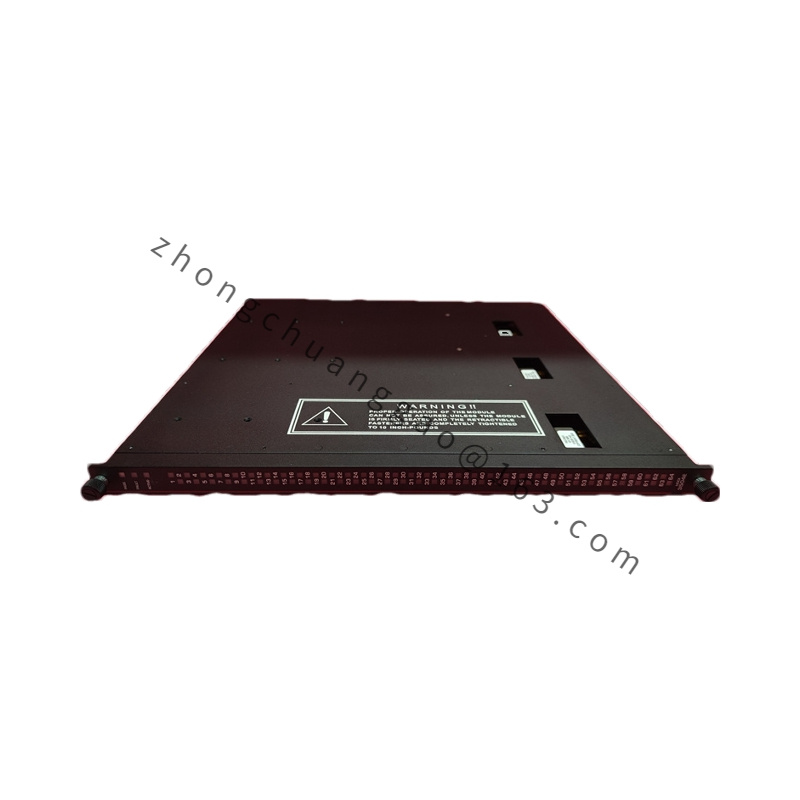

Petroleum and Natural Gas Production:

Controls and protects key production equipment like compressors, valves, and wells.

Chemical Plants:

Ensures safe operation of chemical processes involving toxic or flammable materials.

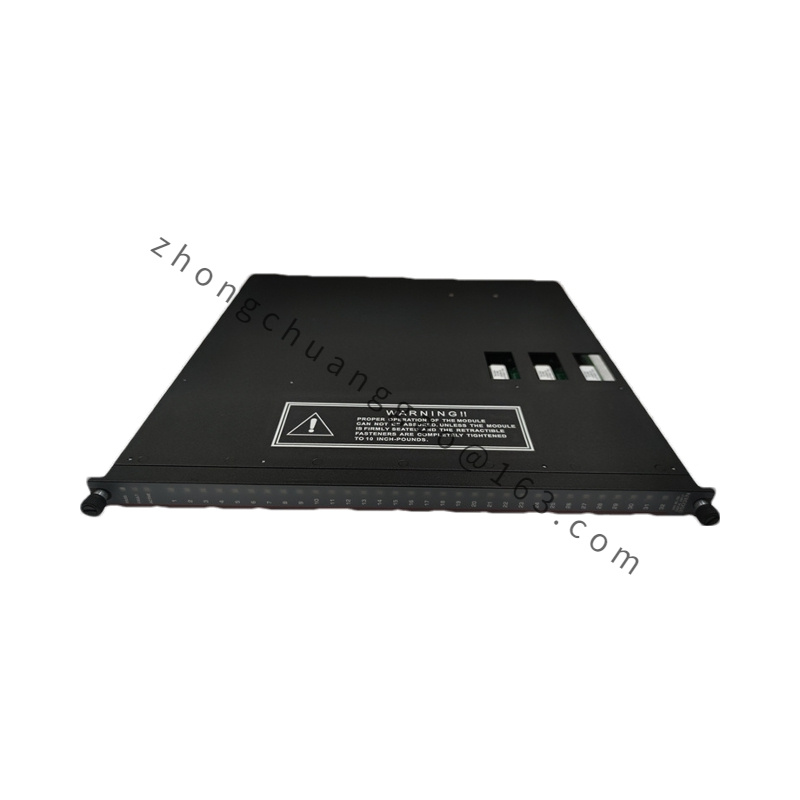

Power Plants:

Enhances the safety and reliability of power generation processes.

Pharmaceutical Industry:

Ensures the safety and compliance of manufacturing processes.

Other Process Industries:

Used in industries with high requirements for process safety, such as pulp and paper, food and beverage, and more.