Detailed content

Technical Specifications

Manufacturer: Schneider Electric Industrial Automation (formerly Invensys, the original developer of Triconex)

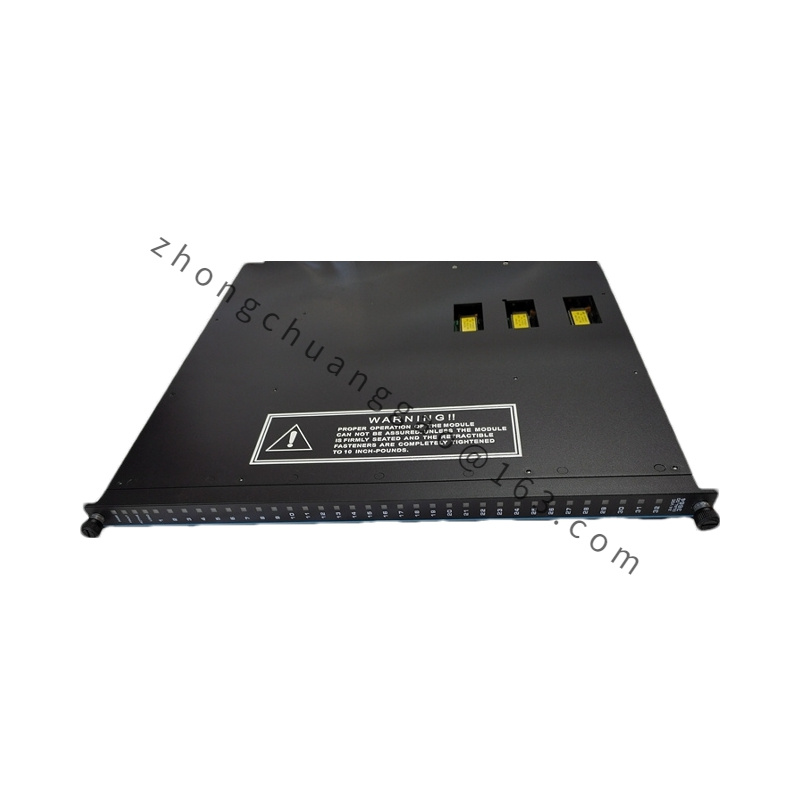

Product Type: Digital Output Module / Controller

Dimensions (Approximate, based on similar Triconex controllers):

Width: 57 mm

Height: 92 mm

Depth: 119 mm

Output Frequency: 10 MHz (Note: This is a general range for output signals, specific to the 3401 module may vary)

Communication Interfaces:

Ethernet

Modbus

Profibus

(Others may be available, depending on configuration)

High-Speed Processing: Capable of real-time acquisition and processing of large volumes of input signals, with corresponding control and response for output signals.

Safety Features:

Access control

Data encryption

Authentication

Redundancy and Fault Tolerance: Features redundant processors, communication interfaces, and power supplies to ensure reliability even in the face of failures.

Functional Characteristics

Programmable Control: The Triconex 3401 is highly programmable, allowing users to configure and program the module to suit specific application requirements.

Multiple I/O Interfaces: Typically offers a variety of input and output interfaces, including analog, digital, and specialized signal types, enabling seamless integration with other devices and systems.

Security and Safety: Incorporates robust security measures to protect system and data integrity, making it ideal for use in safety-critical applications.

Monitoring and Fault Diagnosis: Equipped with monitoring capabilities to track module status and generate alerts in case of faults, facilitating prompt troubleshooting and maintenance.

Compatibility: Designed to be compatible with various industrial control systems and supports multiple communication protocols, enhancing interoperability.

Application Scenarios

The Triconex 3401 finds its application in numerous industries that require high levels of safety and reliability in process control. Some of the key application areas include:

Oil and Gas: For monitoring and controlling critical processes in oil and gas production, processing, and transportation.

Chemical Industry: In the chemical sector, where precise control and safety shutdowns are essential to prevent accidents and ensure product quality.

Power Generation: Used in power plants, particularly for turbine control and safety systems, ensuring uninterrupted power supply.

Nuclear Power: In nuclear power facilities, where safety is paramount, the Triconex 3401 contributes to the implementation of robust safety instrumented systems (SIS).

Process Manufacturing: Any industry that relies on complex process control, such as pharmaceuticals, food and beverage, and pulp and paper, can benefit from the reliability and versatility of the Triconex 3401.