Detailed content

Technical Specifications

| Specification | Details |

|---|---|

| SIL Certification | SIL-3 certified |

| TMR Architecture | Triple Modular Redundancy (TMR) protection |

| Processor Technology | Advanced processor technology |

| Core Processor Speed | Up to 1.2 GHz (as per some sources) |

| Memory | 1 GB DDR3 RAM, support for up to 16 GB storage |

| QSPI Flash Storage | 32 MB capacity |

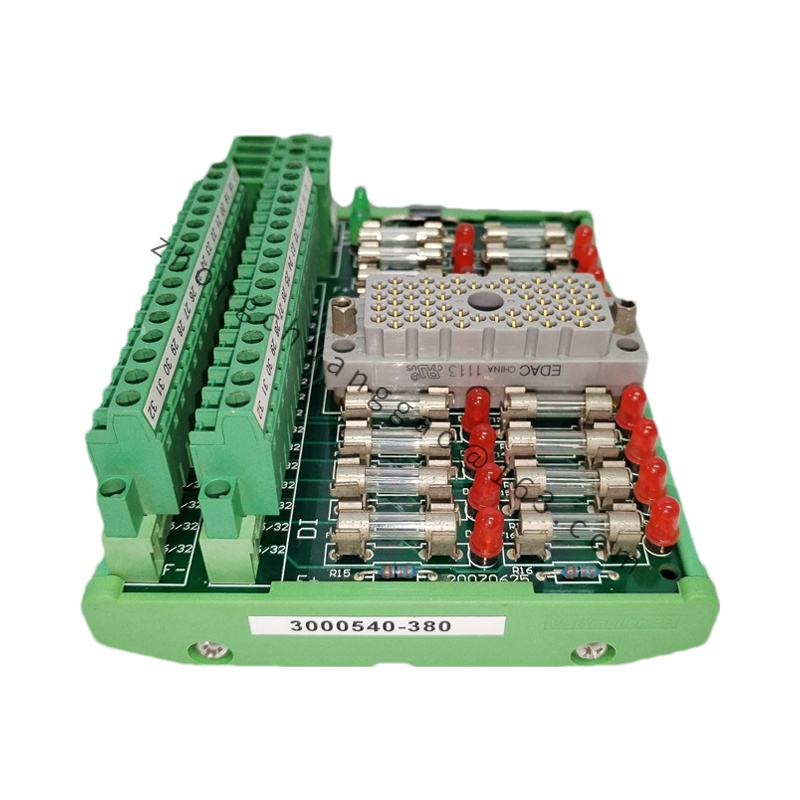

| I/O Points | Up to 96 I/O points |

| Input Voltage | 18-32VDC |

| Power Consumption | Maximum 22 Watts |

| Operating Temperature | -40°C to +70°C (some sources indicate -20°C to 55°C) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5-95%, non-condensing |

| Shock Resistance | 30g, 11ms |

| Vibration Resistance | 5g, 10-150Hz |

Functional Characteristics

- High Reliability and Stability:

- Designed with high-quality materials and manufacturing processes to ensure reliable operation in harsh environments.

- Equipped with advanced diagnostics and fault-tolerant features to maintain system safety and availability.

- Advanced Processing Power:

- Features an advanced processor capable of handling complex control tasks with high processing speeds and data handling capabilities.

- Programmable Functionality:

- Supports programming, allowing users to implement custom control logic and algorithms to meet specific application requirements.

- Diverse Communication Interfaces:

- Offers various communication interfaces, including serial ports, Ethernet ports, USB ports, and supports protocols such as TCP/IP, UDP, RS-232, RS-422, RS-485, and CAN.

- Easy-to-Use and Maintain:

- Provides a user-friendly interface and development tools for easy configuration, debugging, and maintenance.

- Supports remote monitoring and management, reducing on-site maintenance efforts.

- Integrated Motion Control:

- In addition to traditional logic control, Triconex 3009 also integrates motion control capabilities, supporting up to 16 axes of motion control.

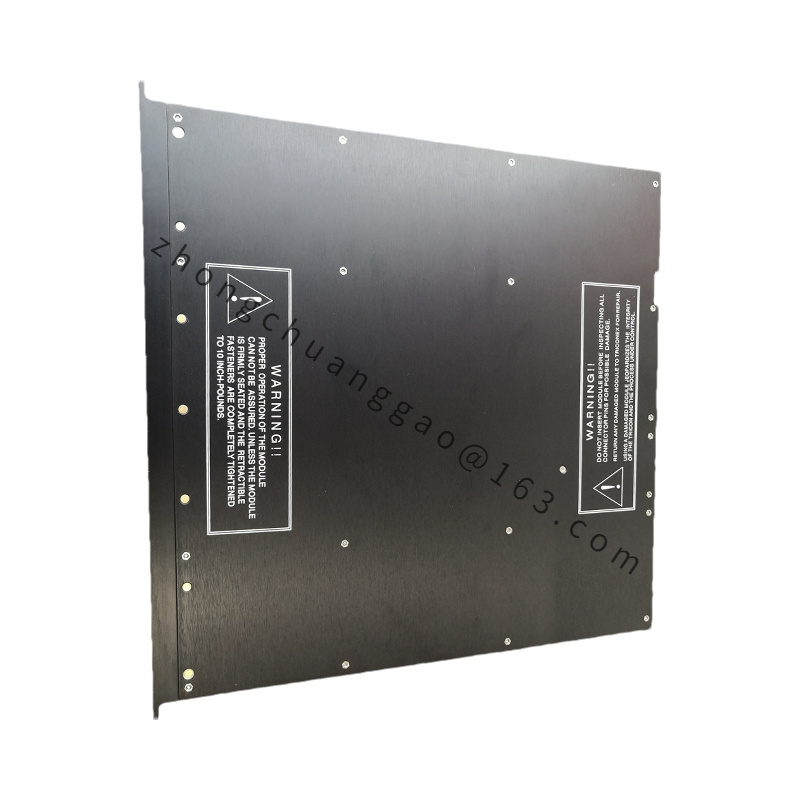

- Compact and Rugged Design:

- Features a compact and robust all-metal enclosure with a reinforced coating for excellent vibration resistance and installation sturdiness.

Application Scenarios

Triconex 3009 is ideally suited for safety-critical applications in various industries, including:

- Oil and Gas: Emergency shutdown systems (ESD), fire and gas detection systems, burner management systems (BMS), turbomachinery control systems, and pipeline monitoring and control systems.

- Power Generation: Steam turbine control, compressor anti-surge control, and other critical process control systems.

- Chemical Processing: Safety instrumented systems (SIS) and other safety-critical control applications.

- Nuclear Industry: Safety-related control systems requiring the highest levels of reliability and redundancy.