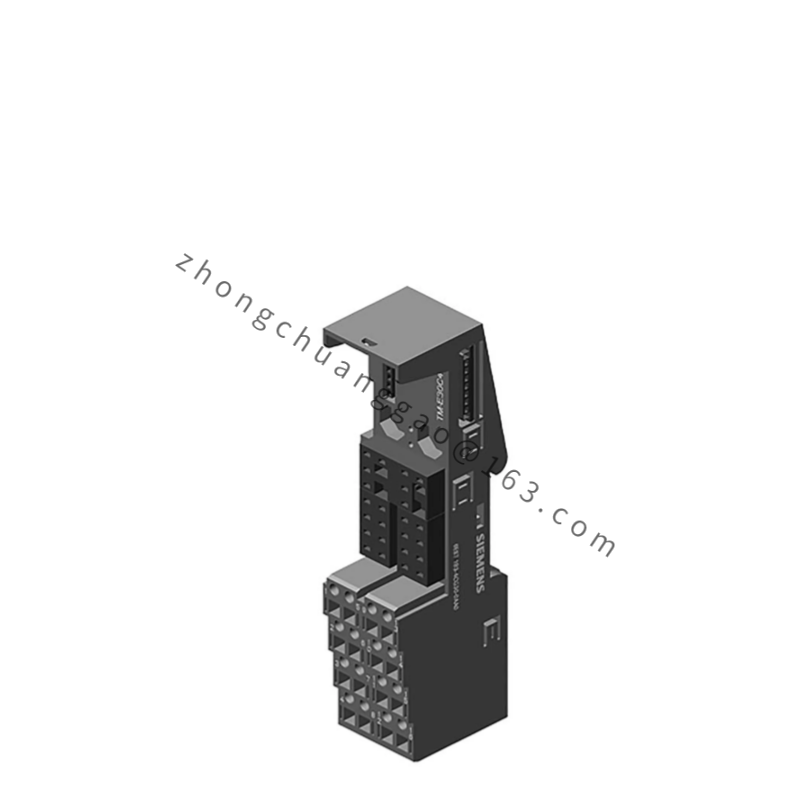

SIEMENS 6SE7031-0TE60-Z DC INVERTER: High-Performance Drive Module for Industrial Automation

The SIEMENS 6SE7031-0TE60-Z DC INVERTER is a high-performance drive solution designed for precision control in industrial automation systems. It ensures efficient and reliable power conversion between DC power sources and motors, facilitating smooth operation and energy savings in various manufacturing processes.

Detailed content

Operating Voltage:360-480V DC

Power Handling Capacity:Up to 60kW

Frequency Range:400Hz

Control Interface:Profibus DP

Protection Rating:IP20

Motor Control Type:Vector Control

Efficiency Rating:98%

Incorporated Fault Management System:Yes

Communication Protocol Support:EtherCAT, CANopen

Integrating advanced semiconductor technology, the SIEMENS 6SE7031-0TE60-Z DC INVERTER delivers unparalleled performance for industrial automation systems. This high-efficiency inverter is designed to optimize motor control, ensuring smooth operation and energy savings in manufacturing processes.

With its robust IP21 protection class, the unit is suitable for industrial environments where dust and minor water splashes may occur, ensuring reliable operation even under challenging conditions. The inclusion of a communication interface compatible with Profibus DP facilitates seamless integration with other Siemens control systems, enhancing system efficiency and flexibility.

Featuring a wide operating voltage range from 200V to 1000V DC, this inverter is versatile enough to meet the power requirements of various industrial applications. Its high output power capacity, up to 200kW, allows it to handle heavy-duty loads with ease, making it ideal for demanding industrial settings.

The inverter’s compatibility with TIA Portal, Siemens’ comprehensive software suite for automation engineering, enables users to easily configure and monitor the system parameters. This feature simplifies the setup process and streamlines maintenance tasks, reducing downtime and enhancing productivity.

Efficient cooling mechanisms are integrated to ensure optimal performance throughout the inverter’s lifecycle. This results in longer operational life and reduced maintenance costs compared to conventional models, contributing to a more sustainable and cost-effective solution for industrial automation.