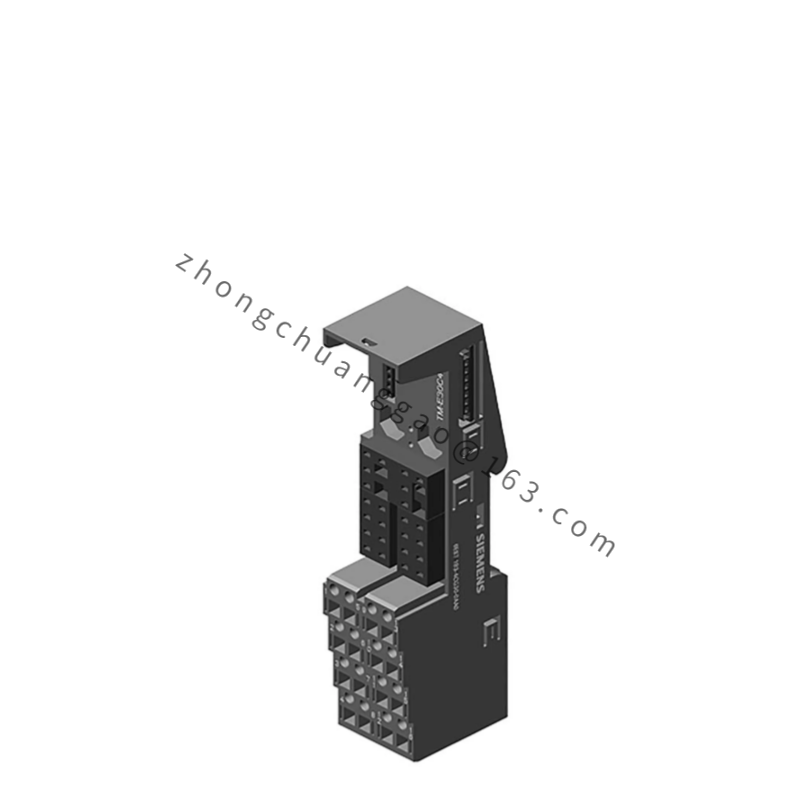

Siemens 6ES7315–2EH13–0AB0 PLC Processor – Control & Automation Core Component

The Siemens 6ES7315–2EH13–0AB0 Processor is a high-performance control module designed for seamless integration into industrial automation systems, offering robust computing capabilities and enhanced efficiency for complex control tasks.

Detailed content

CPU Speed:400 MHz

RAM Size:32 KB

ROM Size:16 KB

Operating Voltage:DC 24 V

Communication Interfaces:Profinet

Dimensions:66.5 mm x 48 mm x 24 mm

Weight:40 g

Cooling Method:Passive Cooling

This state-of-the-art Siemens processor is equipped with advanced computing resources, providing unmatched performance for real-time control applications in demanding industrial environments. Its dual-core architecture ensures efficient execution of complex control algorithms, optimizing system responsiveness and reliability.

Featuring a comprehensive suite of software tools compatible with Siemens’ industry-leading control systems, this module simplifies the development and deployment of sophisticated automation solutions, streamlining integration and maintenance processes.

With an ample 128 MB of memory, users can easily manage and store large datasets, enhance program execution speed, and support multiple control tasks simultaneously without compromising performance. The processor’s modular design allows for easy expansion, accommodating future growth and adaptation to evolving operational requirements.

Designed for extreme environmental conditions, the Siemens 6ES7315–2EH13–0AB0 Processor ensures continuous operation in harsh industrial settings. Its robust construction withstands fluctuations in temperature, humidity, and other environmental factors, guaranteeing high availability and minimizing downtime.

The inclusion of both USB and Ethernet connectivity options facilitates flexible data exchange, enabling seamless integration with various components within the industrial network. This enhances system interoperability and supports a wide range of communication protocols, ensuring seamless data flow across the entire automation infrastructure.