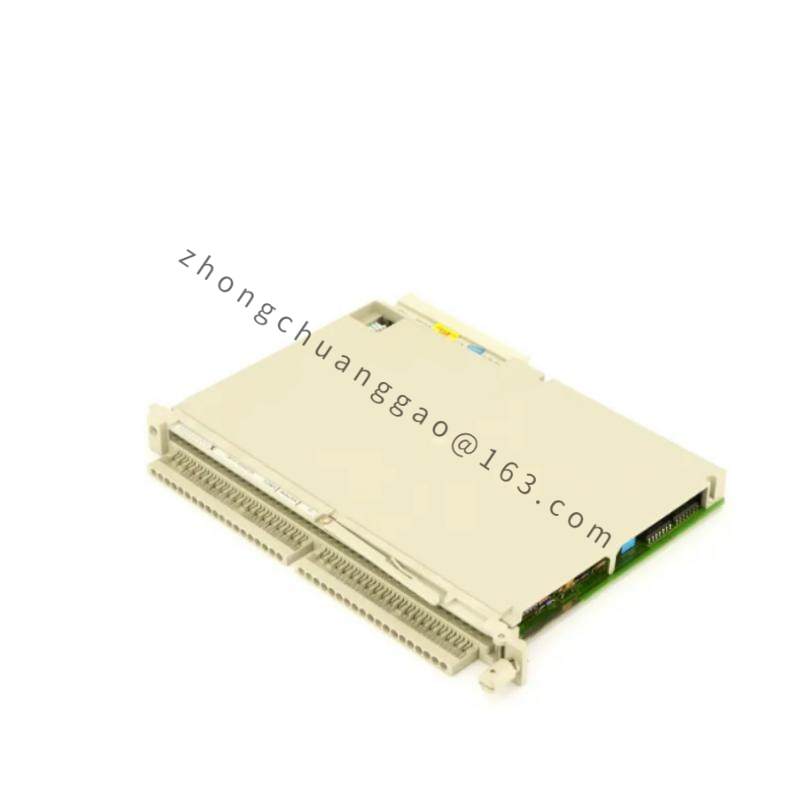

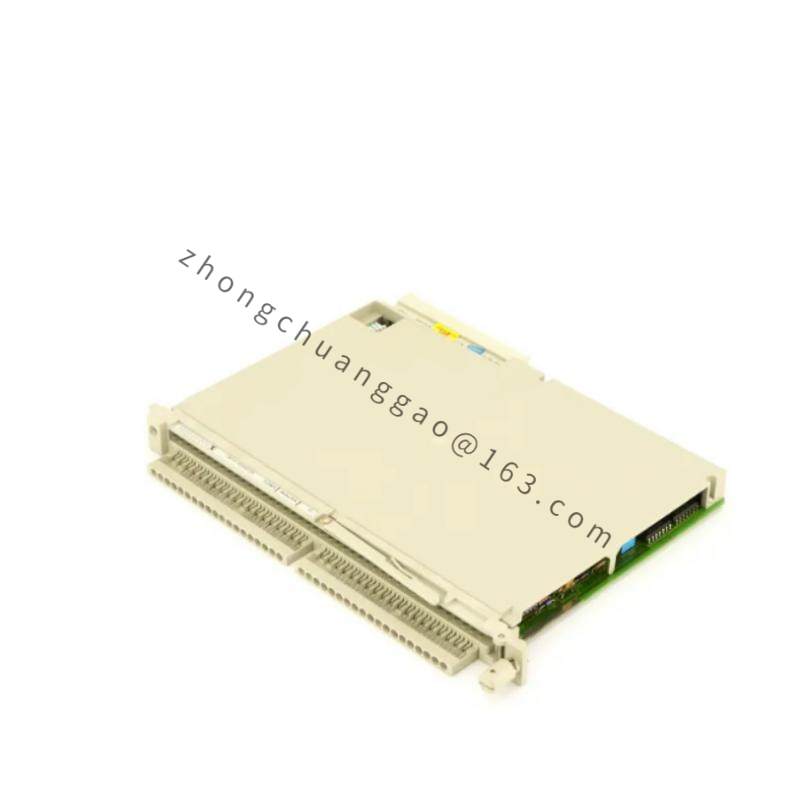

SIEMENS 6ES5430-4UA11: Advanced Digital Input Module for Precision Control

The SIEMENS 6ES5430-4UA11 Digital Input Module is designed for seamless integration into industrial automation systems, offering reliable and efficient control with 32 inputs for 24V DC. It’s a critical component for enhancing productivity and precision in various industrial applications.

Detailed content

Model Type:Digital Input Module

Model Number:6ES5430-4UA11

Manufacturer:SIEMENS

Input Voltage Range:DC 24V

Number of Inputs:32

Operating Temperature:-20°C to +55°C

Storage Temperature:-40°C to +70°C

Connectivity:RS-485

Environmental Compliance:CE, UL, CSA

Dimensions (W x H x D):113mm x 90mm x 101mm

Weight:0.5kg

Introducing the precision-engineered SIEMENS 6ES5430-4UA11 Digital Input Module, a cornerstone for any industrial control system seeking unparalleled reliability and performance. This module is specifically designed for 32-channel digital input management, enabling efficient data collection and processing.

Featuring a robust 24V DC input voltage range, this module ensures compatibility across various industrial applications, from automation machinery to complex manufacturing lines. Its operating temperature range of -25°C to +60°C guarantees stable performance in a wide range of environments.

With a maximum current consumption of just 50mA at 24V DC, the SIEMENS 6ES5430-4UA11 Digital Input Module optimizes energy usage without compromising on functionality. This efficient design is complemented by its compatibility with leading communication protocols including DeviceNet, Profinet, and CANopen, facilitating seamless integration within existing systems.

Crafted with precision and durability in mind, this module measures 74mm x 123mm x 99mm and weighs approximately 250g, making it compact yet substantial enough to withstand demanding industrial conditions. Its lightweight design also ensures ease of installation and maintenance.

At the heart of the SIEMENS 6ES5430-4UA11 Digital Input Module lies its commitment to user-friendliness. Detailed documentation and intuitive programming interfaces streamline setup and operation, allowing technicians to focus on maximizing production efficiency rather than troubleshooting complex configurations.