Digital guide

You are here:

- Home

- Other brands

- Reotron 567LH-DP24

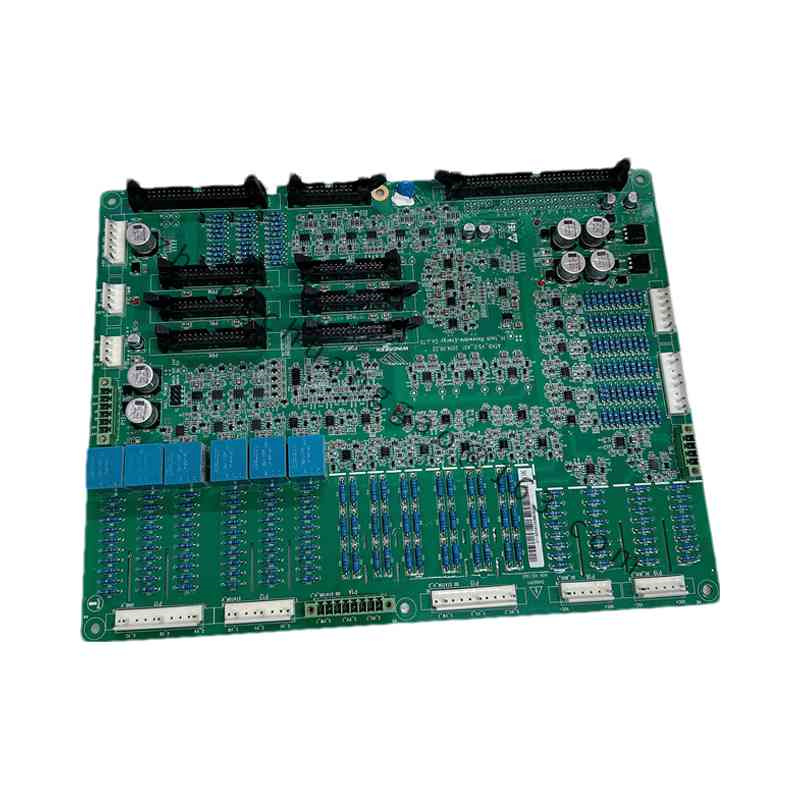

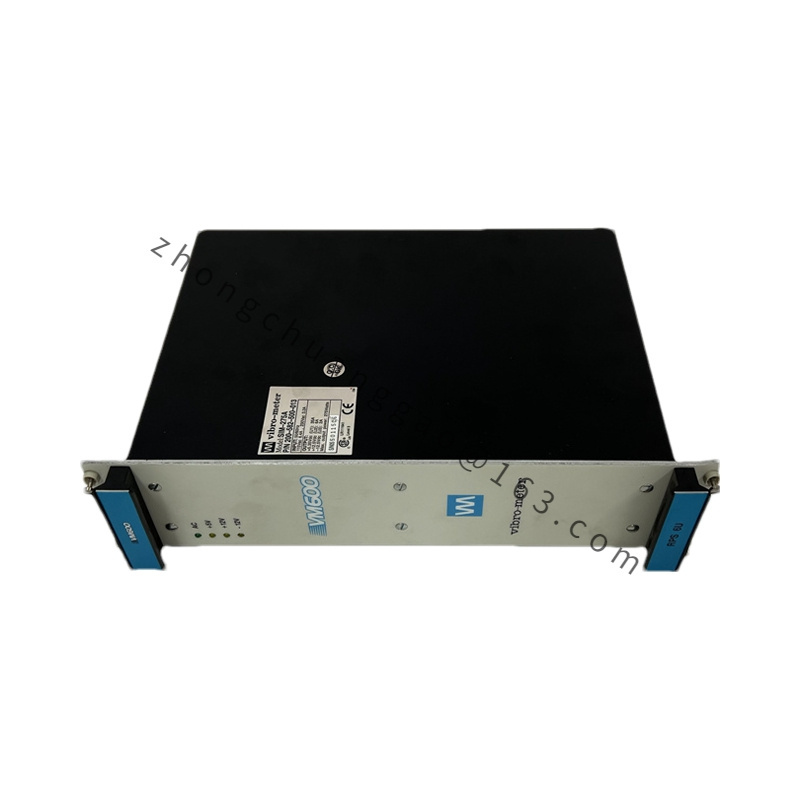

Reotron 567LH-DP24

Reotron 567LH-DP24 is a versatile and high-performance industrial automation component that offers a range of functionalities tailored for various industrial applications. It combines advanced technology with robust design to ensure reliability and precision in diverse environments.

Detailed content

Technical Specifications

- Model Number: Reotron 567LH-DP24

- Power Supply: Designed for connection to 3 x 400 V, 50/60 Hz three-phase power supply

- Communication Interfaces: Supports fieldbus interfaces such as Profibus-DP, DeviceNet, EtherCAT, EtherNet/IP, ProfiNet, or CAN-BUS protocols

- Operating Temperature: 0 to 85°C

- Humidity: 0-95%

- Dimensions (may vary by specific application and model): Approximately 16*25*12 (controller) or standard dimensions for other components like servo motor modules

- Customizability: Available in custom versions for specific applications

Functional Characteristics

- High Precision: Offers high-precision control for accurate manufacturing and processing.

- Versatility: Can be used as voltage, current, or power regulators, ensuring maximum versatility.

- User-Adjustable Parameters: Multiple user-adjustable parameters allow customization and optimization of control according to specific applications.

- Alarm Functionality: Provides alarms for out-of-range conditions and user power loss uncalibration.

Application Scenarios

- Industrial Automation: Used to control robotic arms, conveyor belts, hydraulic and pneumatic equipment, achieving high-precision production and manufacturing processes.

- CNC Machine Tools: Controls movements such as cutting, drilling, milling, and turning for precise part processing.

- Printing and Packaging Machinery: Enhances production efficiency and printing quality by controlling printing, cutting, packaging, and labeling applications.

- Food and Beverage Production: Ensures accurate filling and packaging of products on various equipment like filling machines, sealing machines, and packaging machines.

- Medical Equipment: Controls scanners, surgical robots, drug dispensing devices, and life support systems.

- Aerospace: Utilized in controlling aircraft rudders, landing gear, and gyroscopes.

- Robotics Technology: Widely used in industrial and service robots for highly accurate and programmable motion control.

- Laboratory Equipment: Controls the position and motion of experimental equipment in scientific laboratories and research fields.

- Testing and Measurement: Suitable for testing and measurement equipment such as spectrometers, microscopes, and precision instruments.

.jpg)

-1.jpg)