Detailed content

MVI56-MBP (2)

Technical Specifications

- Compatibility:

- Designed for use with Rockwell Automation ControlLogix series PLCs.

- Fits into a 1756 I/O chassis slot.

- Communication Protocols:

- Modbus TCP/IP: Provides Ethernet-based Modbus communication.

- Modbus RTU: Supports serial Modbus communication (additional serial communication cards may be required).

- Port and Connections:

- Ethernet Port: For Modbus TCP/IP communication.

- Serial Ports: For Modbus RTU communication (typically through serial communication expansion cards).

- Power Supply:

- Requires 24V DC power, commonly supplied by the ControlLogix system power supply.

- Dimensions:

- Standard 1756 module size, designed for DIN rail mounting within the ControlLogix chassis.

Functional Features

- Flexible Configuration:

- Configuration is facilitated through ProSoft Configuration Builder (PCB) software.

- Allows for setting Modbus addresses, register mappings, and other communication parameters.

- Data Exchange:

- Supports both Modbus master and slave functions.

- Capable of managing high-speed data transfers between Modbus devices and the ControlLogix PLC.

- High Performance:

- Designed to handle high-throughput data communication with minimal latency.

- Suitable for real-time applications requiring reliable and fast data exchange.

- Diagnostics and Monitoring:

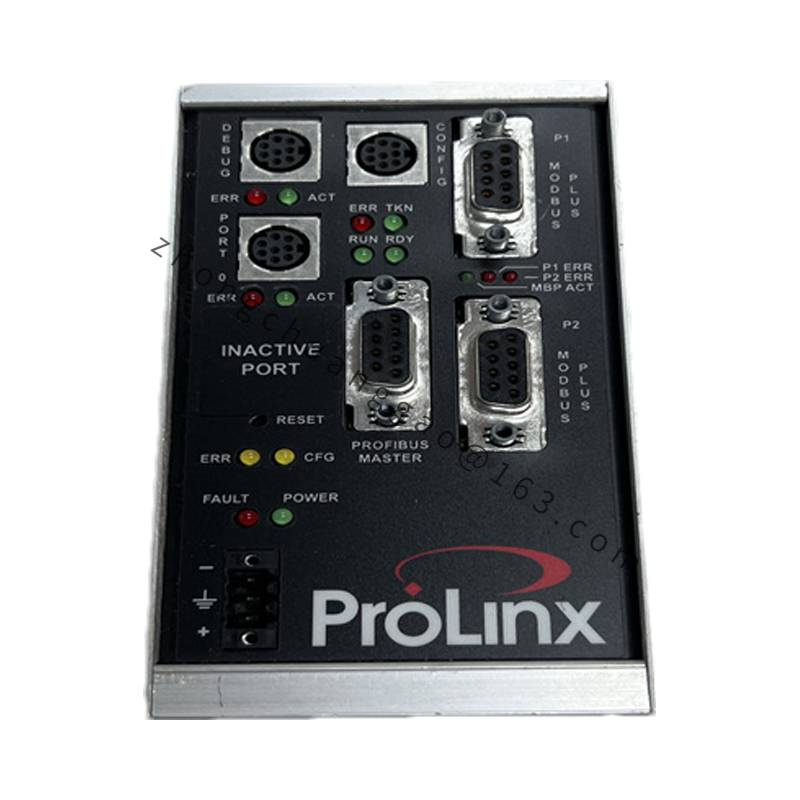

- Includes diagnostic LEDs to indicate module status, communication activity, and errors.

- PCB software provides advanced diagnostic tools and status monitoring.

- Easy Integration:

- Simplifies the integration of Modbus devices into a ControlLogix system.

- Supports a wide range of Modbus devices, enhancing system flexibility.

Application Scenarios

- Industrial Automation:

- Ideal for integrating Modbus devices (such as sensors, actuators, and other peripherals) into a ControlLogix-based automation system.

- Useful in applications requiring centralized control and monitoring of Modbus-based equipment.

- Process Control:

- Facilitates communication in process control systems, where Modbus devices need to interact with ControlLogix PLCs for monitoring and control.

- Data Acquisition:

- Employs in systems where data from Modbus devices needs to be collected and processed by a ControlLogix controller for analysis or further action.

- Device Integration:

- Effective for integrating existing Modbus networks with newer ControlLogix systems, enabling system upgrades and expansions without extensive redesigns.

Additional Considerations

- Software Support: ProSoft Configuration Builder (PCB) software simplifies setup and configuration, allowing users to define communication parameters and manage data mapping.

- Technical Support: For detailed installation instructions, technical support, and troubleshooting, consult ProSoft Technology or authorized distributors.

.jpg)