Detailed content

1. Technical Specifications

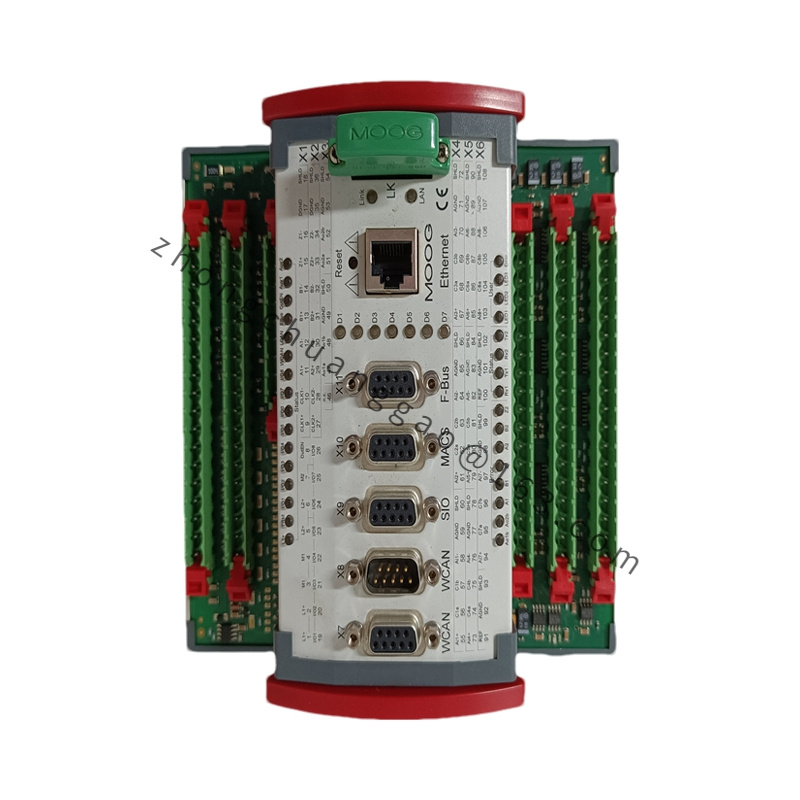

- Model: Moog D136-001-007

- Type: Servo Valve

- Function: Controls the flow of hydraulic fluid to regulate the movement of hydraulic actuators based on electrical input signals.

- Pressure Rating: Typically operates within a specific pressure range suitable for various hydraulic systems. Exact pressure ratings should be checked in the datasheet.

- Flow Rate: Handles specific flow rates as indicated in the datasheet, which are crucial for its application in controlling hydraulic fluid flow.

- Input Signal: Receives electrical control signals (e.g., 0-10V, 4-20mA) to adjust hydraulic flow accurately.

- Response Time: Features rapid response times for quick adjustments and precise control.

2. Key Features

- Precision Control: Provides high accuracy in modulating hydraulic fluid flow, which translates into precise control of hydraulic actuators.

- Durable Construction: Designed to withstand harsh industrial environments with protection against dust, moisture, and vibrations.

- Versatile Applications: Suitable for a wide range of hydraulic systems, offering flexibility in various industrial and aerospace applications.

- Low Hysteresis: Engineered to minimize hysteresis, improving the accuracy and stability of hydraulic control.

3. Application Scenarios

- Industrial Automation: Used in manufacturing and automation systems where precise control of hydraulic actuators is necessary for machinery and equipment.

- Aerospace: Integrated into aerospace systems for controlling hydraulic actuators in aircraft and spacecraft, ensuring reliable performance in critical applications.

- Heavy Machinery: Applied in heavy machinery where precise hydraulic control is essential for optimal performance and safety.

- Test Equipment: Utilized in test rigs and equipment where accurate hydraulic control is needed for performance evaluation and validation.

4. Additional Information

- Installation and Maintenance: Requires proper installation to ensure optimal performance and reliability. Regular maintenance according to Moog’s guidelines will help extend the valve’s operational life.

- Technical Support: Supported by Moog’s technical documentation and customer support services. For detailed installation instructions, troubleshooting, and technical queries, Moog’s support team can provide assistance.