Digital guide

You are here:

- Home

- Ics Triplex

- Ics triplex T9402

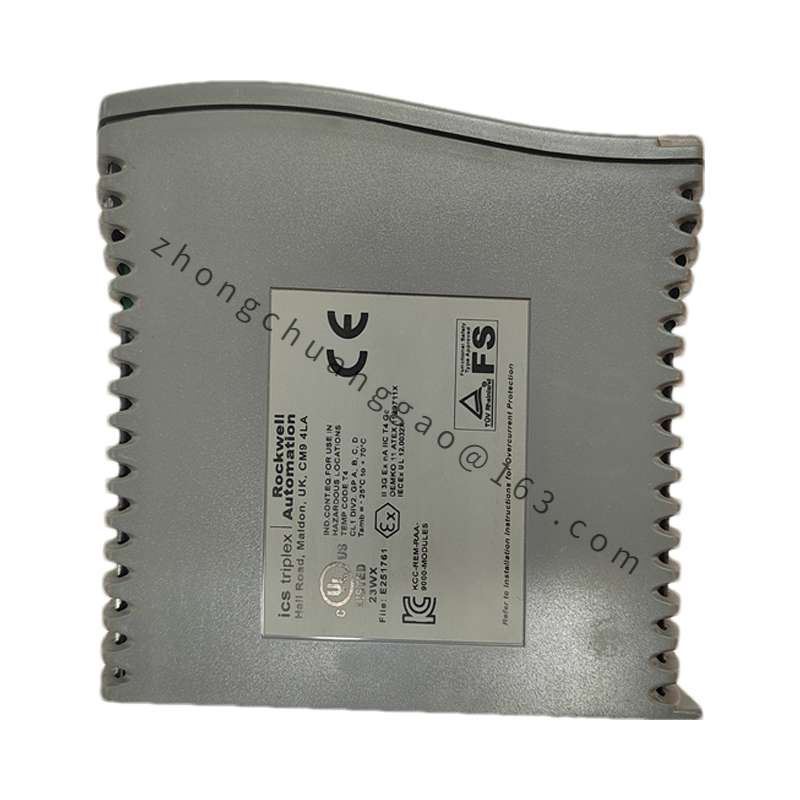

Ics triplex T9402

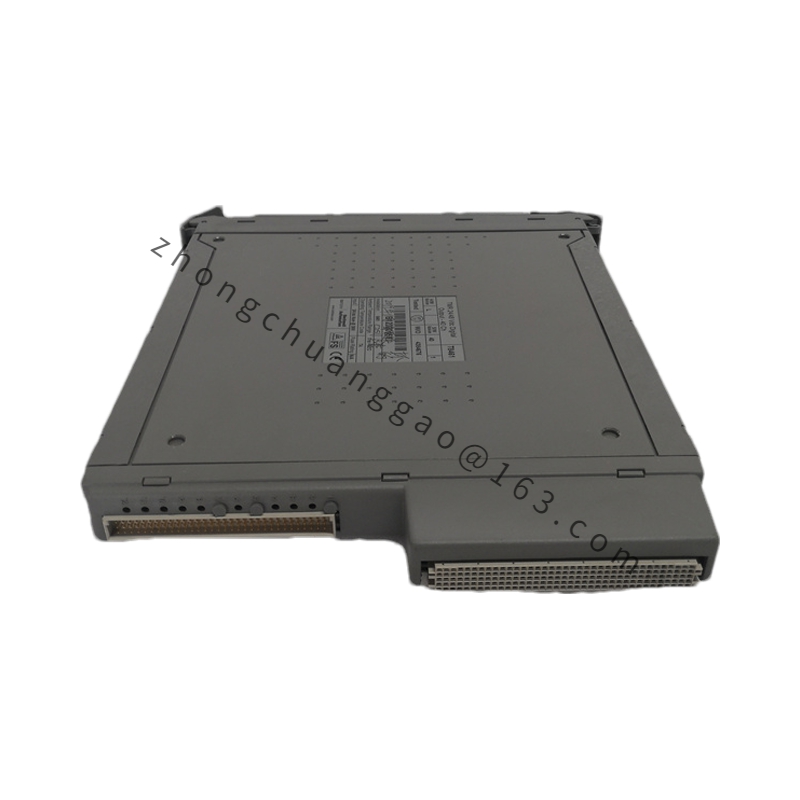

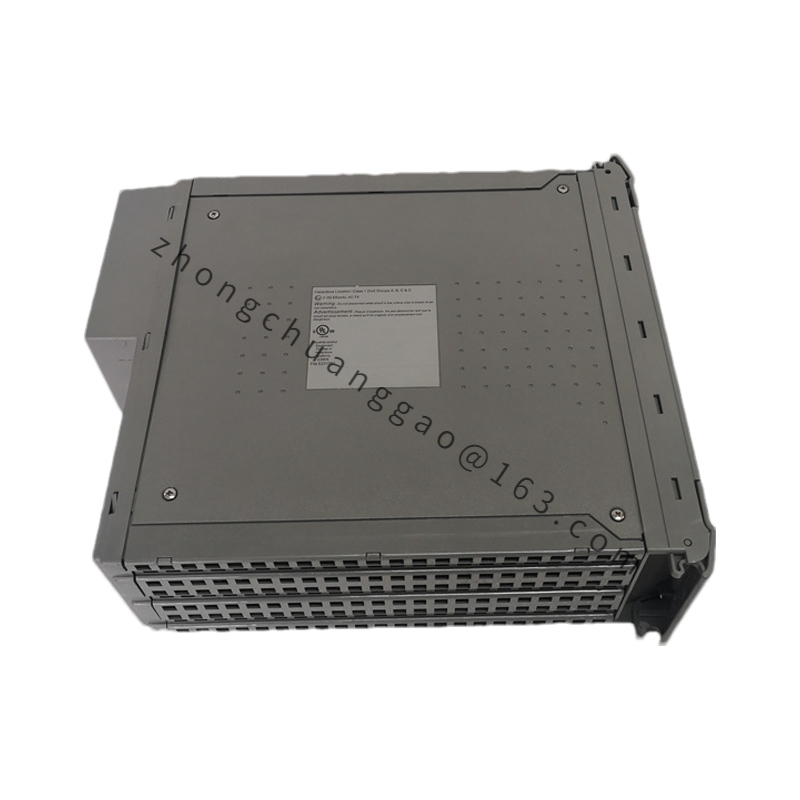

ICS TRIPLEX T9402 is an automation control module designed for industrial automation and control systems. It is a robust and high-performance device that excels in monitoring, controlling, and automating various industrial processes. With its advanced features, the T9402 module is suitable for applications in various industries such as chemicals, power, oil and gas, manufacturing, and water treatment.

Detailed content

Technical Specifications

- Processor: Equipped with powerful processors capable of handling large amounts of data and complex control algorithms.

- Memory: Features sufficient memory to support efficient operation and data storage.

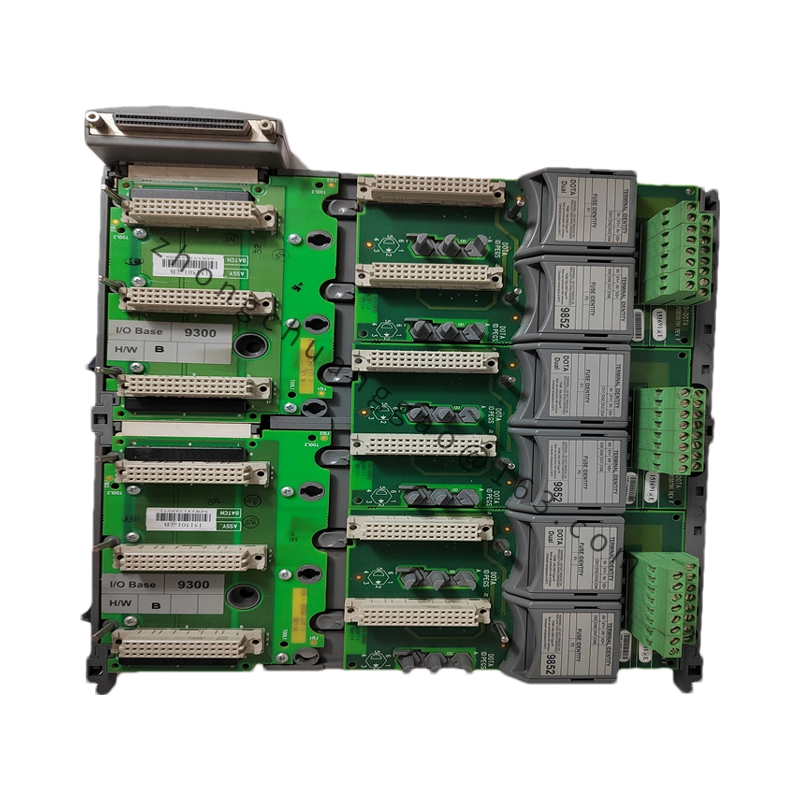

- Input/Output Channels: Supports multiple input and output channels for connecting sensors, actuators, and other external devices.

- Communication Interfaces: Supports various communication interfaces and protocols for seamless data exchange with other systems.

- Operating Temperature: Designed to operate within a wide temperature range, ensuring stability in harsh industrial environments.

- Power Supply: Accepts a standard industrial power supply range.

- Safety Features: Incorporates safety functions to protect the system from unauthorized access and attacks.

Functional Characteristics

- High Reliability: The T9402 module is designed with advanced reliability technology, ensuring stable system operation even in harsh industrial environments.

- High-performance Processing Capability: Equipped with powerful processors to handle large data volumes and complex control algorithms.

- Multi-channel Input/Output: Supports multiple input and output channels, enabling connection and monitoring of multiple sensors, actuators, and other devices.

- Communication Interfaces: Supports various communication interfaces and protocols for data exchange with other control systems, monitoring systems, and host computers.

- Real-time Control: Provides real-time control capabilities to respond to rapidly changing industrial process requirements.

- Programmability: The module is programmable, allowing users to customize control logic and algorithms to meet different application needs.

- Self-diagnosis and Alarm: Features self-diagnosis functions to monitor device status and generate alarms when issues are detected.

- Data Recording and Analysis: Supports data recording and analysis functions, enabling performance analysis and optimization.

- Scalability: Supports scalability, allowing users to add more input/output channels or extended functions as needed.

Application Scenarios

- Chemical Industry: Used in process control, monitoring reaction conditions, and ensuring safe and efficient production.

- Power Industry: Applied in power plants, substations, and power distribution systems for monitoring and control of various equipment.

- Oil and Gas Industry: Utilized in monitoring and controlling complex production processes to ensure efficient and safe operations.

- Manufacturing: Employed in controlling production lines, machinery, and processes to improve production efficiency and quality.

- Water Treatment: Used in monitoring and adjusting parameters in water treatment processes to ensure water quality standards are met.