Digital guide

You are here:

- Home

- Ics Triplex

- Ics triplex T8403

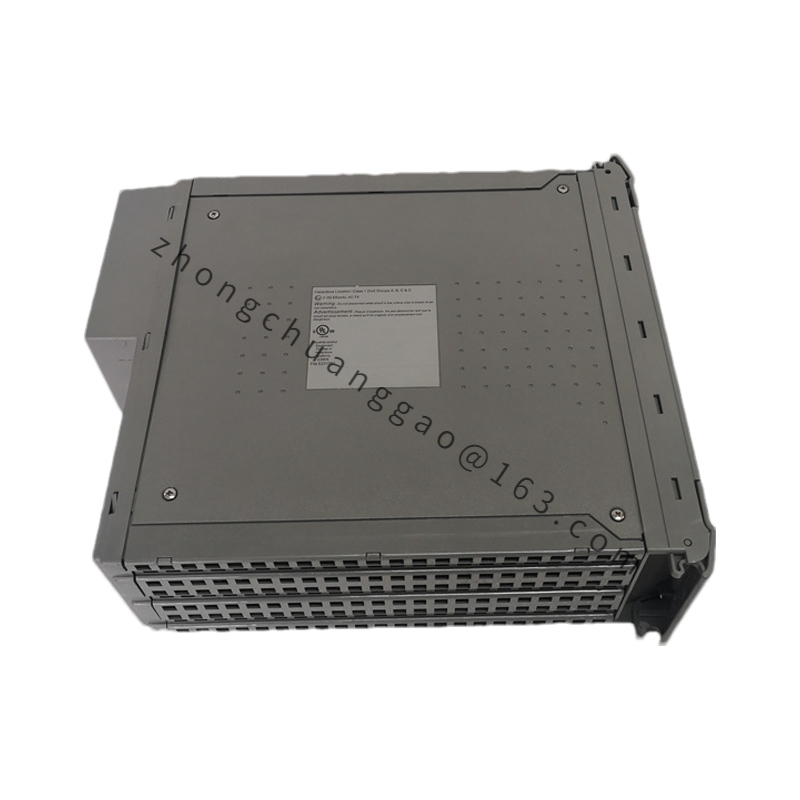

Ics triplex T8403

ICS TRIPLEX T8403 is an advanced automation control module designed for industrial automation and control systems. It is a key component in achieving various automation control tasks, leveraging cutting-edge technology to ensure efficient and reliable operation across diverse industrial applications.

Detailed content

Technical Specifications

- Input Voltage Range: DC 24V

- Output Voltage Range: DC 24V

- Operating Temperature Range: -20°C to +70°C

- Storage Temperature Range: -40°C to +85°C

- Humidity Range: 10% to 90% RH

- Dimensions: 112mm x 70mm x 123mm

- Weight: Approximately 0.5 kg

- Processor Type: Trustworthy TMR Processor

- Voltage Range for Operation: 20 to 32 V DC

- Maximum Load: 80 W

- Processor Clock Speed: 100 MHz

- I/O Interface: Triple Redundant Module Inter-bus

- SOE Buffer Size: 1000 events, transferable to a CI buffer of 4000 events

Functional Characteristics

- Programmability: The T8403 module allows for customization and configuration of control logic based on specific application requirements.

- Multi-channel Support: It provides multiple input and output channels for connecting sensors, actuators, and other devices, enabling simultaneous processing of multiple signals.

- High-performance Control: The module supports high-performance control, including fast response time, high-precision position control, and speed control.

- Communication Interfaces: Equipped with communication interfaces such as Ethernet and serial ports for data exchange and communication with other control and monitoring systems.

- Fault Detection and Diagnosis: Built-in fault detection and diagnosis functions monitor the module’s status and the health of control signals, providing alarms and notifications.

- Modular Design: Designed in a modular form for easy installation, maintenance, and expansion.

- Security: Complies with relevant safety standards and certification requirements to ensure secure operation.

- Flexibility: Adapts to different input and output signal types to meet varying application needs.

- Real-time Control: Provides real-time control functionality for applications requiring immediate response.

Application Scenarios

- Oil and Gas Industry: Used in well control, process control, and valve control to ensure the safety and stability of production processes.

- Chemical Industry: Plays a crucial role in controlling chemical reactors, collecting and monitoring sensor data, and regulating processes to ensure accuracy and reliability.

- Power Industry: Widely applied in power plants, substations, and distribution systems for control and protection, ensuring stable power system operation.

- Manufacturing: Essential for production line control, robot control, and process monitoring, enhancing production efficiency, quality, and automation levels.

- Process Control Applications: Suitable for various process control applications such as water treatment, food and beverage production, and pharmaceuticals, ensuring process stability and consistency.