Digital guide

You are here:

- Home

- Ics Triplex

- Ics triplex T8310

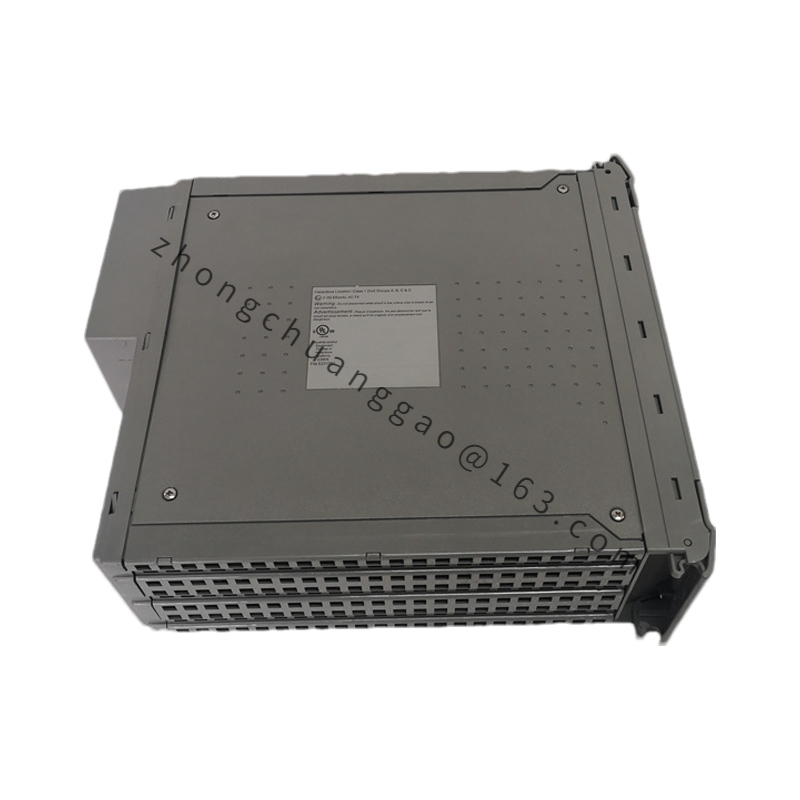

Ics triplex T8310

ICS TRIPLEX T8310 is a high-performance control module that is widely used in various industrial automation and control systems. It is part of the Triple Modular Redundant (TMR) system, ensuring high redundancy and reliability. Provided by ICS Triplex (now part of Schneider Electric or Emerson, depending on the source), this module combines hardware and software to provide an integrated control solution.

Detailed content

Technical Specifications

- Operating Voltage: May vary depending on the application. In some communication card applications, the operating voltage is 265V. For ICS TRIPLEX branded control system modules, other voltages such as 180V may apply.

- Output Frequency: In certain applications, such as communication cards, the output frequency ranges from 70-275Hz.

- Certifications: The product has passed multiple test certifications, such as the IEC61000 series standards, ensuring its stability and reliability in electromagnetic environments.

- Environmental Adaptability: It has a wide operating temperature range, such as -10-70°C (with an optional wide temperature range of -40~+85°C). The relative humidity should be ≤90% (non-condensing).

- Dimensions and Weight: Dimensions may vary depending on the specific application. For example, in some communication card or controller applications, the dimensions may be 234mm (length) × (width range 421-1060mm) × (height not specified). In other applications, such as mechanical characteristic descriptions, the dimensions may be 132mm × 105mm × 52mm. The weight also varies, ranging from 800g to 2-7kg depending on the product type and configuration.

Functional Characteristics

- High Performance: Equipped with advanced hardware and software design, it has excellent processing capabilities and control accuracy.

- Reliability: After strict quality control and environmental adaptability testing, it has high reliability and stability, capable of operating in harsh industrial environments for extended periods.

- Flexibility: Supports multiple communication protocols and interface standards, allowing seamless connection and communication with different types of devices and systems.

- Ease of Programming and Maintenance: Provides rich programming interfaces and development tools, as well as comprehensive fault diagnosis and remote maintenance functions.

- Redundancy: As part of a TMR system, it ensures stable operation of the system in case of failures.

- Programmability: Can be programmed to adapt to different applications and industrial needs.

- Safety: Incorporates safety features to ensure system stability and reliability.

Application Scenarios

- Oil and Gas: Used in automation control for processes such as oil drilling, refining, and natural gas processing.

- Chemicals: Used for process control and automation in chemical plants.

- Electricity: Used for automation control in power generation units and grid scheduling.

- Water Treatment: Used for automation management in water treatment facilities, including tap water and wastewater treatment.

- Pharmaceuticals: Used for automation control of pharmaceutical production lines and monitoring of product quality.

- Manufacturing: Used for automation control of various production lines to improve production efficiency and product quality.

- Aerospace: Used in flight control and navigation systems.

- Railway and Transportation Systems: Used for signal control and traffic management.

- Marine and Maritime: Used for control and monitoring in marine and maritime applications.