Detailed content

2、 Functional characteristics

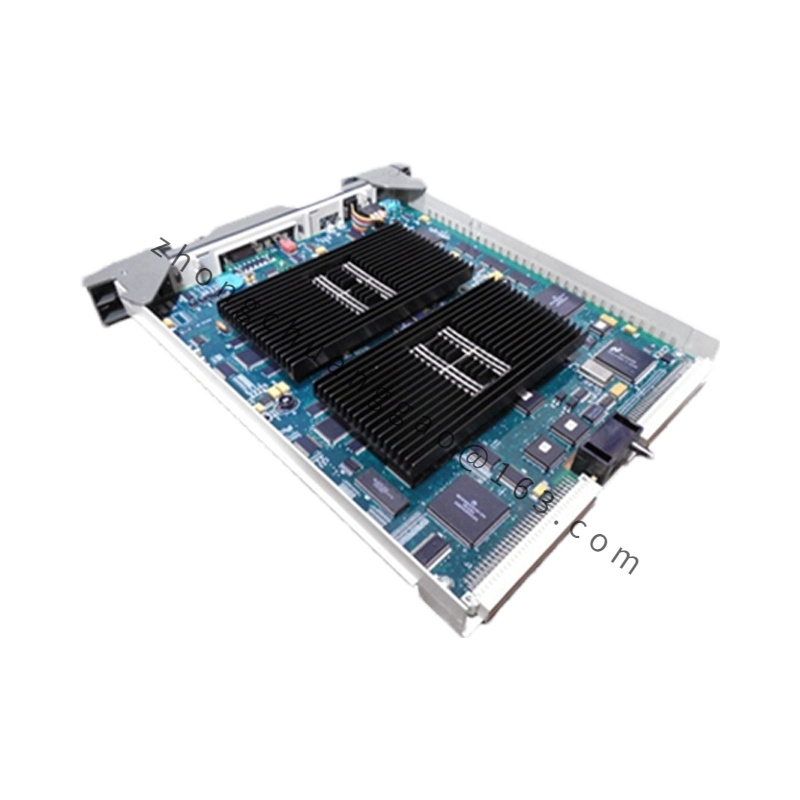

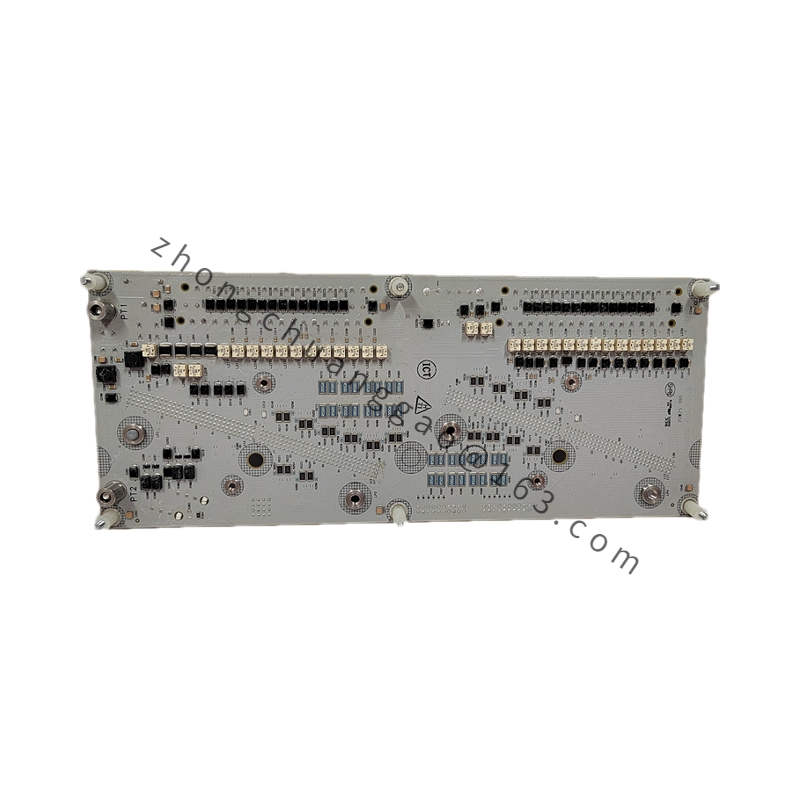

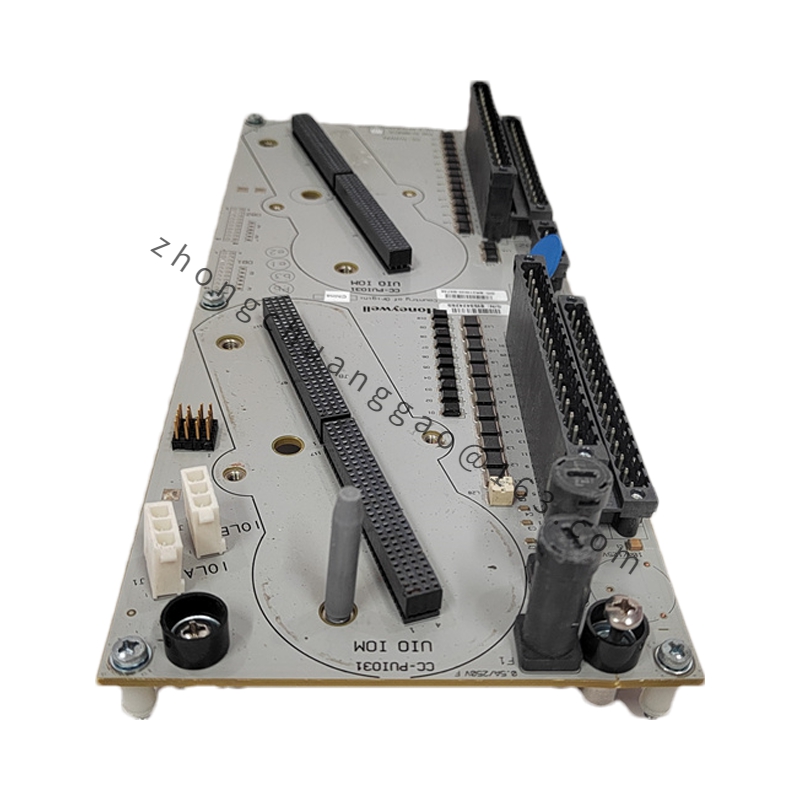

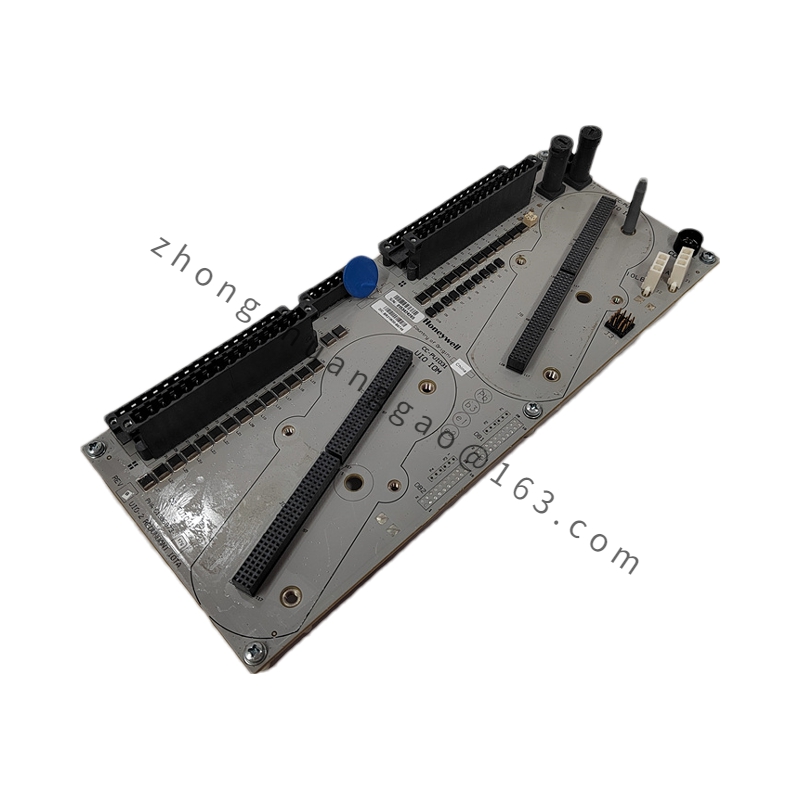

Data processing and control: Honeywell CC-PUIO31 can receive input signals from sensors, process them, and output control signals to control other devices or systems.

Communication Interface: This module is equipped with a communication interface that allows for data exchange and communication with other devices or systems, which may include serial communication, network communication, or other types of communication protocols.

Configuration and programming: Support configuration and programming through software or configuration tools to meet specific application requirements. Users can customize the behavior of modules, set parameters, or adjust control logic.

Monitoring and Diagnosis: With monitoring and diagnostic functions, it can detect its own status, performance or faults, and provide corresponding indications or alarms, which helps maintain the stability and reliability of the system.

Reliability and Stability: As a product from Honeywell, the CC-PUIO31 module inherits Honeywell’s reliability and stability in the field of industrial automation, enabling long-term stable operation in harsh industrial environments.

3、 Application scenarios

Honeywell CC-PUIO31 is widely used in various industrial fields due to its versatility and high reliability, including but not limited to:

Oil and natural gas: used to measure and control parameters such as pressure, temperature, flow rate, liquid level, etc. during the extraction, processing, and transportation of oil and natural gas.

Chemical industry: Accurate measurement and control of key parameters in the production, storage, and transportation of chemicals.

Power industry: Monitor and control the operation status of power equipment in power plants, substations and other power facilities.

Food and Beverage: Ensure that the temperature, pressure, and other parameters during the production process of food and beverage meet the standards to ensure product quality.

Pharmaceutical: In the production process of drugs, precise control of key parameters is carried out to ensure the quality and safety of drugs.

Metallurgy: In the metallurgical process, real-time measurement and control of parameters such as temperature, pressure, and flow rate are carried out to ensure the stability and efficiency of the production process.

.jpg)

.jpg)