Detailed content

Technical Specifications

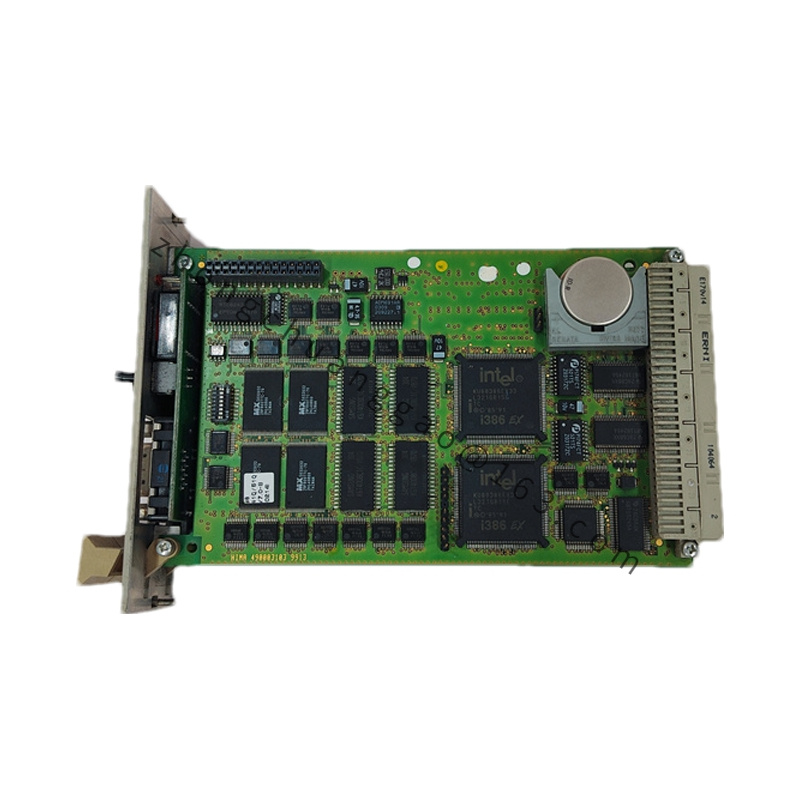

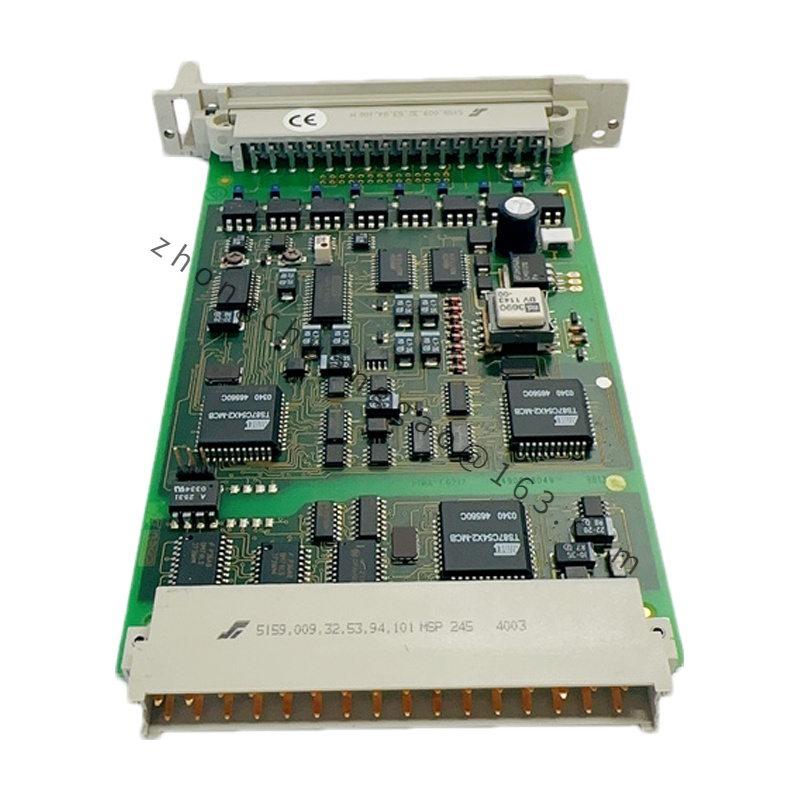

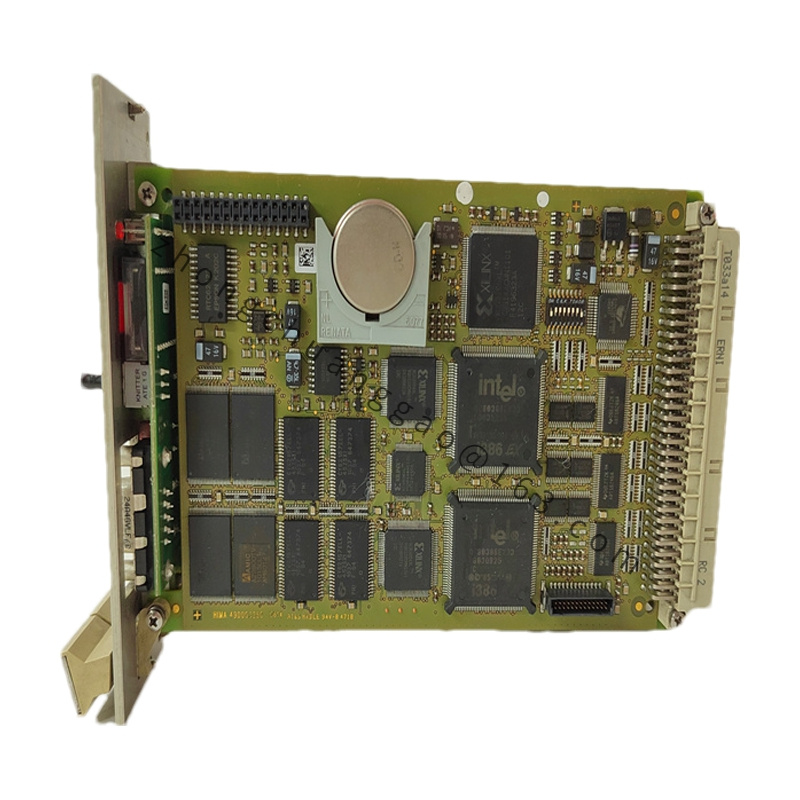

- Model: F8650X

- Type: Safety-Related Input/Output (I/O) Module

- System Compatibility: Compatible with HIMA’s HIMax and HIQuad safety systems.

- I/O Channels: The F8650X typically features multiple I/O channels for both digital and analog signals. The exact number and types of channels can vary based on the specific configuration of the module.

- Input/Output Types:

- Digital Inputs: Used to receive discrete signals from various field devices.

- Digital Outputs: Used to send discrete signals to actuators or alarms.

- Analog Inputs: Measure analog signals such as temperature, pressure, or flow.

- Analog Outputs: Send analog signals to control devices.

- Signal Range: Supports various signal ranges and types, including 0-20 mA, 4-20 mA, and voltage inputs/outputs, depending on the specific module configuration.

- Safety Integrity Level (SIL): Certified for SIL 3 applications according to IEC 61508, ensuring it meets the highest standards of safety integrity.

- Redundancy: Designed with redundancy options to enhance system reliability and ensure continuous operation in the event of a module or component failure.

- Isolation: Features galvanic isolation between channels to prevent interference and protect against electrical faults.

Features

- High Reliability: Engineered for use in safety-critical applications, offering high reliability and robustness in harsh industrial environments.

- Real-Time Processing: Provides real-time processing of inputs and outputs, ensuring that safety-related decisions and actions are executed without delay.

- Flexible Configuration: Supports flexible configuration of I/O channels, allowing the module to be tailored to specific application requirements.

- Integrated Diagnostics: Includes extensive diagnostic capabilities to monitor the status of I/O channels and detect potential issues, aiding in maintenance and troubleshooting.

- Compatibility: Easily integrates with existing HIMA safety systems and can also interface with other systems through standard communication protocols.

Application Scenarios

- Oil and Gas Industry: Used in exploration, drilling, and refining operations where precise control and monitoring of equipment are crucial for safety and operational efficiency.

- Chemical Processing: Employed in chemical plants to monitor and control hazardous processes, ensuring that safety systems can respond effectively to any deviations.

- Power Generation: Utilized in power plants to manage and control critical systems such as turbines, boilers, and generators, where safety and reliability are essential.

- Emergency Shutdown Systems (ESD): Plays a key role in ESD systems, providing reliable input and output channels for emergency shutdown procedures.

- Fire and Gas Detection Systems: Used in fire and gas detection systems to process signals from detectors and initiate appropriate safety measures.

.jpg)