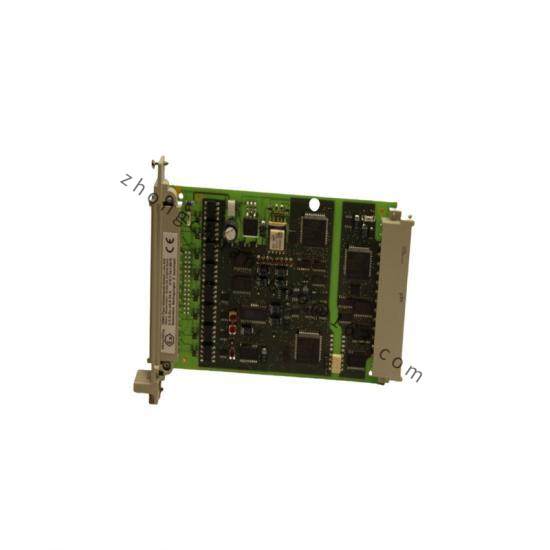

Hima F8627X

he HIMA F8627X is a vital component in safety and control systems, primarily utilized in industries requiring high safety standards, such as oil and gas, chemical processing, and power generation.

Technical Specifications

- Model: F8627X

- Type: Safety-Related Communication Module

- System Compatibility: This module is compatible with HIMA’s HIMax and HIQuad safety systems, specifically designed for use in safety-related applications.

- Function: The F8627X is used for communication between safety controllers and other system components. It ensures that the data transmitted is both reliable and secure, essential for maintaining system integrity in safety-critical environments.

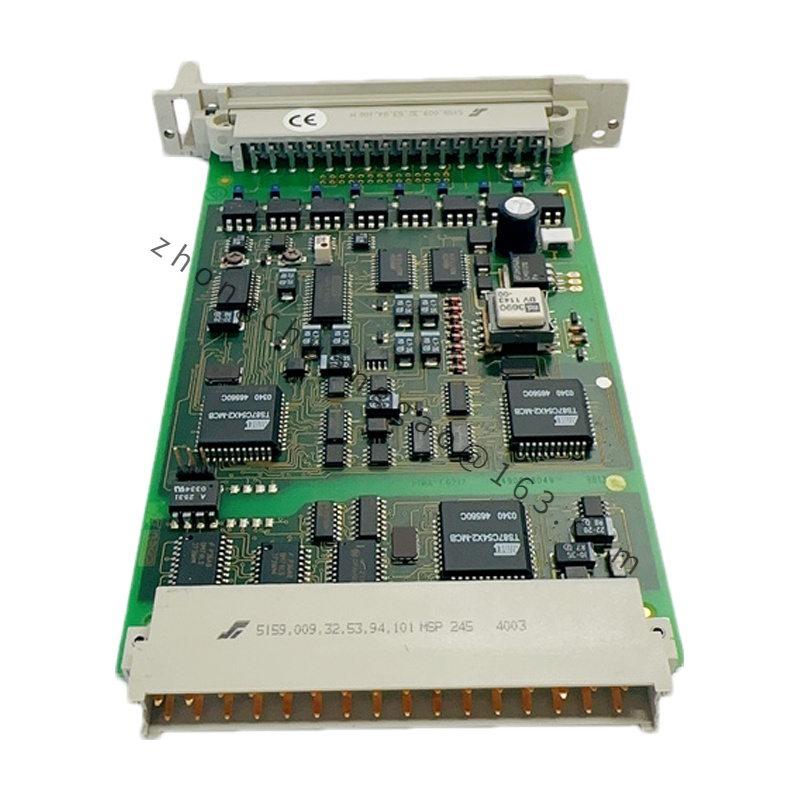

- Communication Protocols: The module typically supports various industrial communication protocols, such as Profibus, Modbus, or proprietary safety protocols designed for HIMA systems. This ensures compatibility with a wide range of devices and systems.

- Safety Integrity Level (SIL): Certified for use in SIL 3 applications according to IEC 61508 standards, making it suitable for the highest levels of safety-critical applications.

- Redundancy: The F8627X supports redundant configurations to ensure continuous operation even if one communication path fails, enhancing system reliability.

- Diagnostics: The module includes built-in diagnostics to monitor communication status, detect errors, and report any issues in real-time, facilitating quick troubleshooting and maintenance.

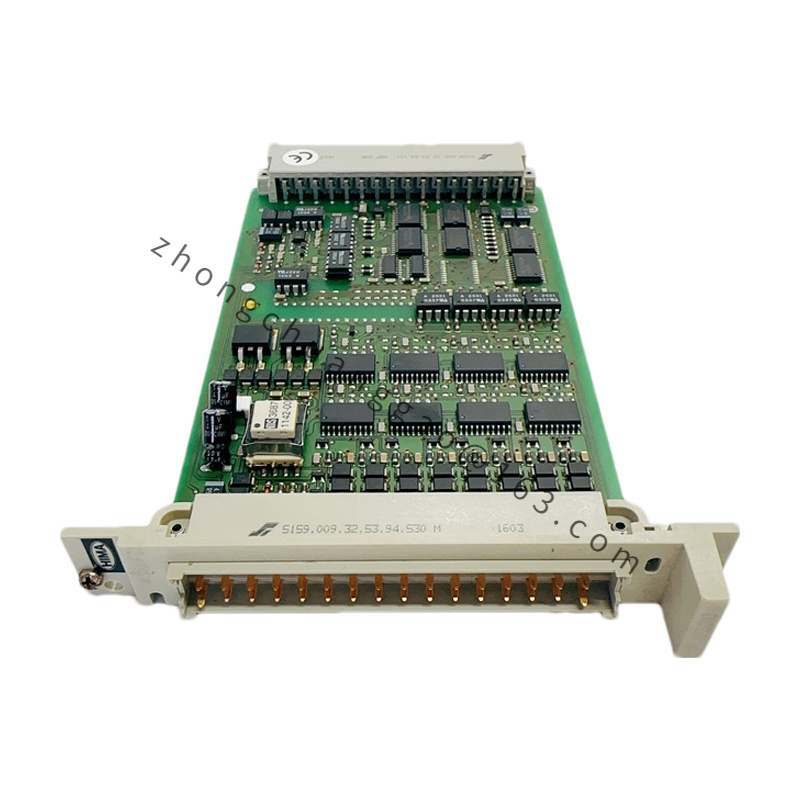

Features

- High Reliability: Designed for demanding industrial environments, the F8627X offers high reliability, ensuring that communication between safety controllers and other system components remains uninterrupted.

- Secure Communication: Implements robust security features to protect communication channels from unauthorized access or tampering, critical in maintaining the safety of the entire system.

- Real-Time Data Exchange: Capable of real-time data exchange, the module ensures that safety-related data is transmitted and processed without delay, enabling timely responses to potential hazards.

- Ease of Integration: The F8627X can be easily integrated into existing HIMA safety systems, as well as with third-party systems, providing flexibility in system design and expansion.

- Configurable: The module allows for configuration to meet specific application needs, including setting up communication parameters and defining redundancy paths.

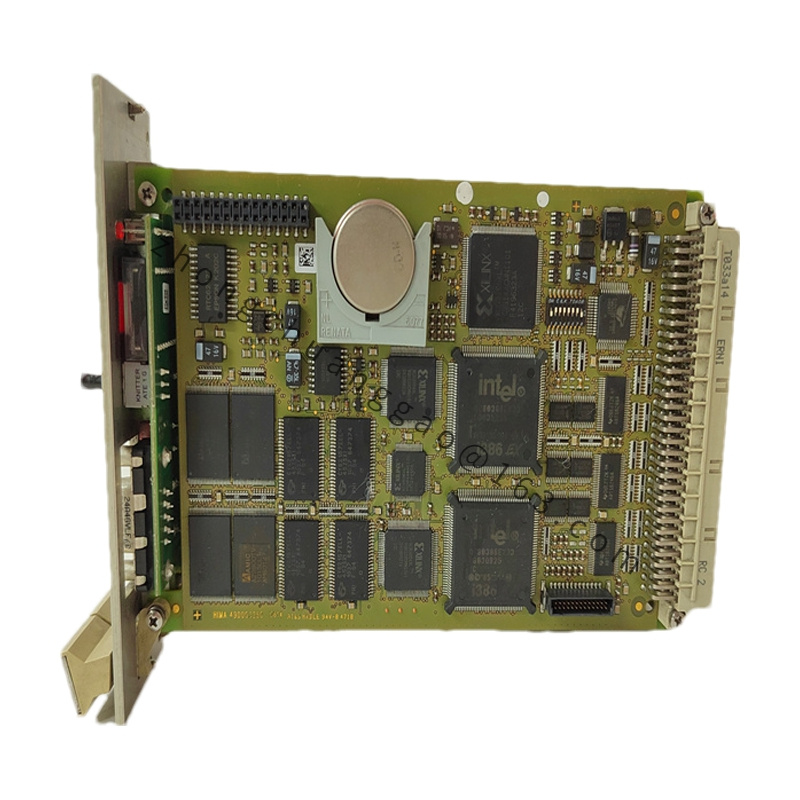

Application Scenarios

- Oil and Gas Industry: Used in offshore platforms and refineries where maintaining secure and reliable communication between safety systems is critical for preventing catastrophic failures.

- Chemical Processing: In chemical plants, the F8627X facilitates communication between controllers managing hazardous processes, ensuring that safety systems can respond swiftly to any anomalies.

- Power Generation: Employed in power plants for the safe operation of turbines, boilers, and other critical systems, where it ensures that safety controllers communicate effectively to prevent accidents.

- Emergency Shutdown Systems (ESD): Plays a crucial role in ESD systems, where it ensures that all parts of the safety system can communicate effectively during an emergency, enabling a coordinated shutdown.

- Fire and Gas Detection Systems: Used to link sensors and controllers in fire and gas detection systems, ensuring that alarms and mitigation measures are triggered quickly and reliably in case of an incident.

Additional Information

Detailed content

Technical Specifications

- Model: F8627X

- Type: Safety-Related Communication Module

- System Compatibility: This module is compatible with HIMA’s HIMax and HIQuad safety systems, specifically designed for use in safety-related applications.

- Function: The F8627X is used for communication between safety controllers and other system components. It ensures that the data transmitted is both reliable and secure, essential for maintaining system integrity in safety-critical environments.

- Communication Protocols: The module typically supports various industrial communication protocols, such as Profibus, Modbus, or proprietary safety protocols designed for HIMA systems. This ensures compatibility with a wide range of devices and systems.

- Safety Integrity Level (SIL): Certified for use in SIL 3 applications according to IEC 61508 standards, making it suitable for the highest levels of safety-critical applications.

- Redundancy: The F8627X supports redundant configurations to ensure continuous operation even if one communication path fails, enhancing system reliability.

- Diagnostics: The module includes built-in diagnostics to monitor communication status, detect errors, and report any issues in real-time, facilitating quick troubleshooting and maintenance.

Features

- High Reliability: Designed for demanding industrial environments, the F8627X offers high reliability, ensuring that communication between safety controllers and other system components remains uninterrupted.

- Secure Communication: Implements robust security features to protect communication channels from unauthorized access or tampering, critical in maintaining the safety of the entire system.

- Real-Time Data Exchange: Capable of real-time data exchange, the module ensures that safety-related data is transmitted and processed without delay, enabling timely responses to potential hazards.

- Ease of Integration: The F8627X can be easily integrated into existing HIMA safety systems, as well as with third-party systems, providing flexibility in system design and expansion.

- Configurable: The module allows for configuration to meet specific application needs, including setting up communication parameters and defining redundancy paths.

Application Scenarios

- Oil and Gas Industry: Used in offshore platforms and refineries where maintaining secure and reliable communication between safety systems is critical for preventing catastrophic failures.

- Chemical Processing: In chemical plants, the F8627X facilitates communication between controllers managing hazardous processes, ensuring that safety systems can respond swiftly to any anomalies.

- Power Generation: Employed in power plants for the safe operation of turbines, boilers, and other critical systems, where it ensures that safety controllers communicate effectively to prevent accidents.

- Emergency Shutdown Systems (ESD): Plays a crucial role in ESD systems, where it ensures that all parts of the safety system can communicate effectively during an emergency, enabling a coordinated shutdown.

- Fire and Gas Detection Systems: Used to link sensors and controllers in fire and gas detection systems, ensuring that alarms and mitigation measures are triggered quickly and reliably in case of an incident.