Detailed content

Technical Specifications

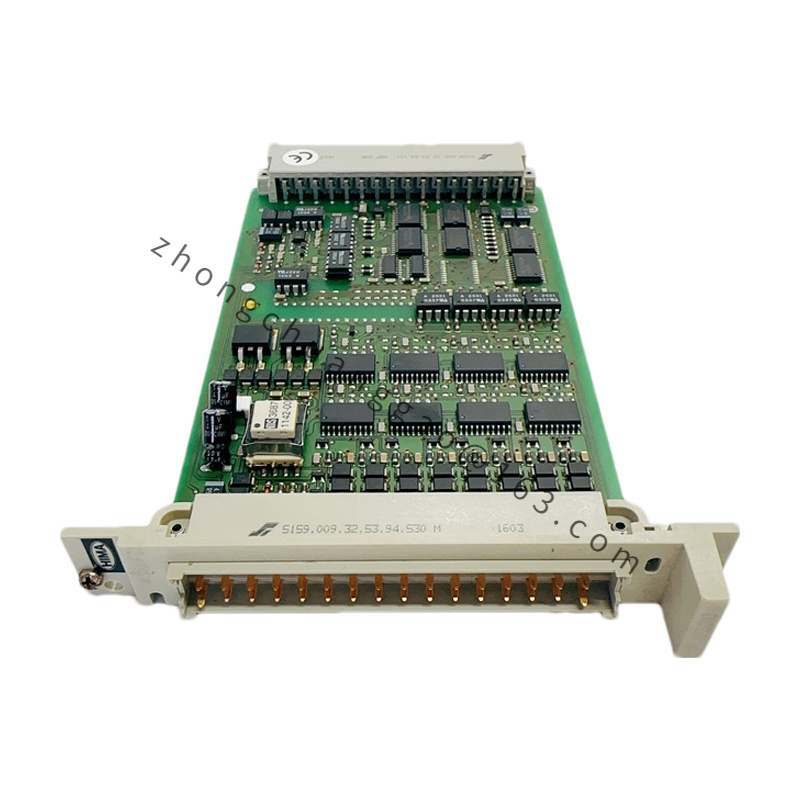

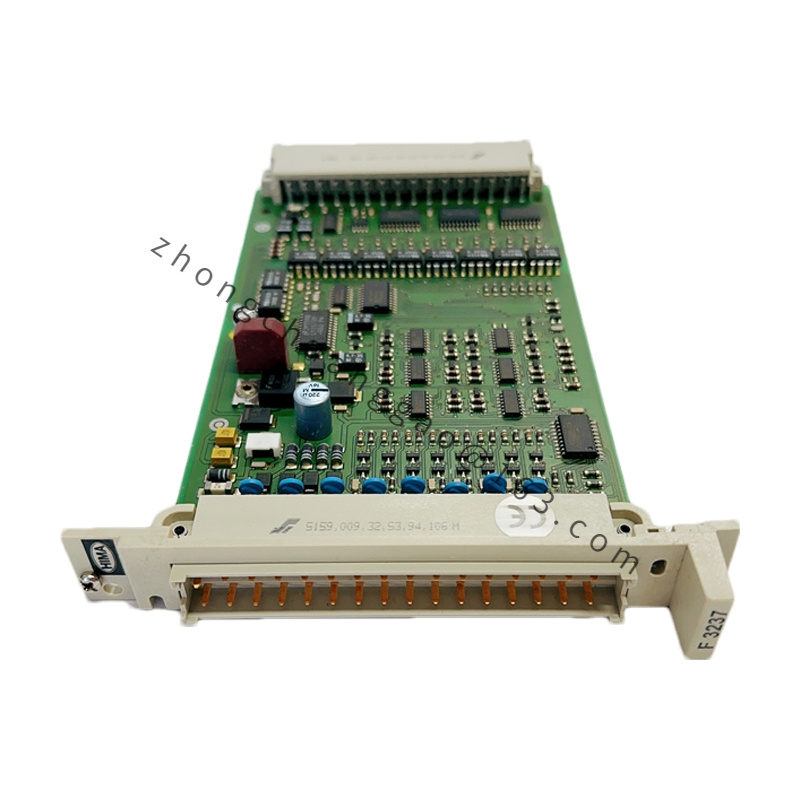

- Model: F8621A

- Type: Central Processing Unit (CPU) Module

- System Compatibility: Compatible with HIMA’s HIMax and HIQuad safety systems, designed for use in safety-related applications.

- Processor: The F8621A typically features a high-performance processor capable of handling complex safety logic and control tasks.

- Memory: Includes both volatile and non-volatile memory for storing the program code, system configuration, and operational data. The non-volatile memory ensures that critical data is retained even during power failures.

- Communication Ports: The module is equipped with multiple communication interfaces, such as Ethernet, serial, and fieldbus connections, allowing it to integrate with various network configurations and other system components.

- Safety Integrity Level (SIL): Certified for use in SIL 3 applications according to IEC 61508 standards, making it suitable for high-risk industrial environments where safety is paramount.

- Redundancy: Supports various levels of redundancy, including processor redundancy, to ensure continuous operation in the event of a hardware failure.

- Diagnostics: Built-in diagnostics for monitoring the health and status of the CPU, including self-tests, error detection, and status indicators.

Features

- High Reliability: Designed to operate in harsh industrial environments, the F8621A is built for long-term reliability and stability, crucial for safety-critical applications.

- Real-Time Processing: Capable of executing safety-related functions in real-time, ensuring that the system can respond promptly to any hazardous situations.

- Configurable Logic: Supports complex safety logic, allowing users to configure the CPU to meet specific application requirements, such as emergency shutdown systems, fire and gas detection, or turbine control.

- Integrated Safety and Control: The F8621A can handle both safety and control functions within the same system, streamlining the architecture and reducing the need for separate systems.

- Extensive Diagnostics: Comprehensive diagnostics help in early detection of faults, enabling preventive maintenance and reducing unplanned downtime.

Application Scenarios

- Emergency Shutdown Systems (ESD): The F8621A is commonly used in ESD applications, where it monitors critical process parameters and initiates shutdown procedures to prevent accidents.

- Fire and Gas Detection Systems: In environments with a high risk of fire or gas leaks, the module processes inputs from sensors and triggers alarms or mitigation measures to protect personnel and equipment.

- Turbine Control Systems: Ensures safe and efficient operation of turbines in power plants by managing control loops and safety interlocks.

- Chemical Processing: Used in chemical plants for managing safety interlocks, controlling hazardous reactions, and ensuring compliance with safety regulations.

- Oil and Gas Industry: Deployed in offshore and onshore facilities for safety instrumented systems (SIS) that protect against catastrophic failures in drilling, refining, and distribution operations.

.jpg)