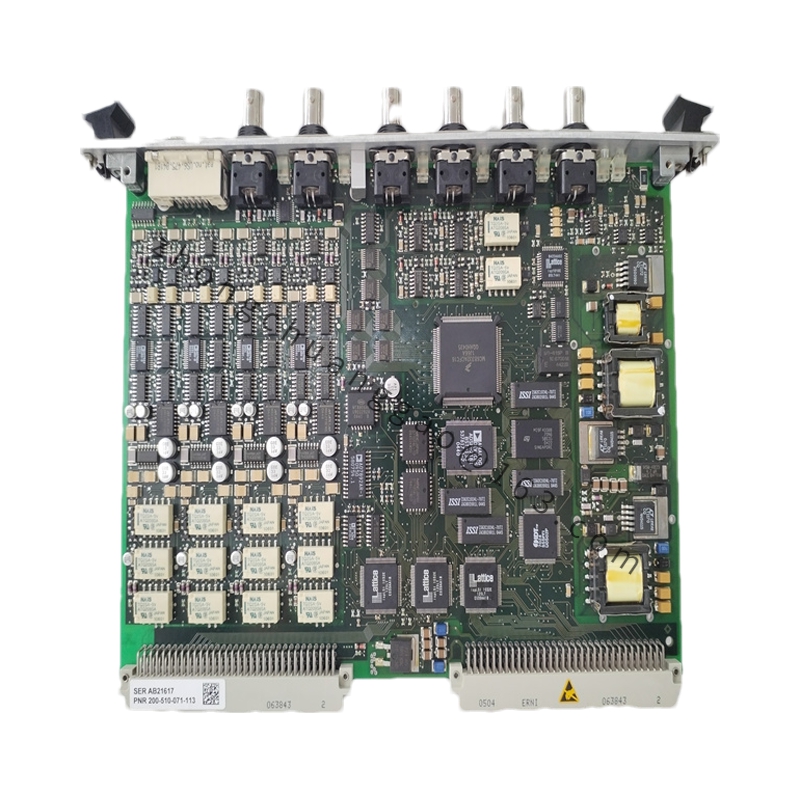

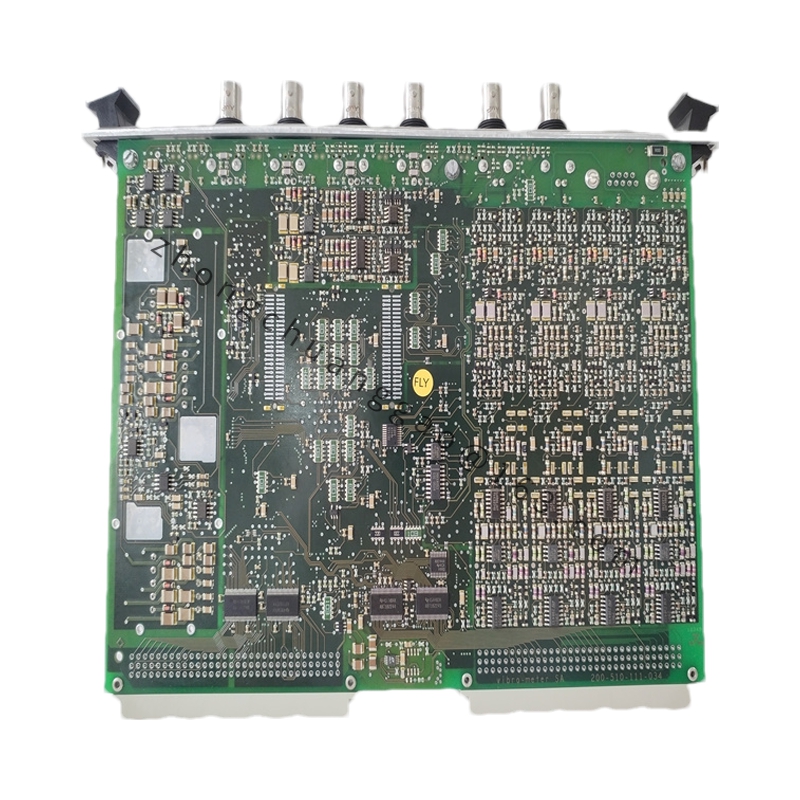

GE VM600 MPC4

The GE VM600 MPC4 is part of General Electric’s VM600 series, known for its advanced capabilities in monitoring and protection systems. The VM600 MPC4 (Monitor and Protection Control 4) is designed for critical applications in various industries, offering sophisticated monitoring and control functionalities.

Detailed content

Technical Specifications:

- Model: VM600 MPC4

- Type: Monitor and Protection Control Module

- Power Supply:

- Voltage: Typically operates with a power supply ranging from 24V DC to 48V DC. Specific voltage requirements should be verified with the datasheet.

- Inputs and Outputs:

- Analog Inputs: Accepts multiple analog inputs for monitoring various parameters (e.g., voltage, current, temperature). The number and type of inputs should be confirmed with the datasheet.

- Digital Inputs/Outputs: Includes digital I/O for interfacing with control and monitoring systems. The exact configuration and number of I/O points should be detailed in the datasheet.

- Communication Ports: Equipped with communication ports for integration with other control systems. Common ports include Ethernet, RS-232, and RS-485. Verify specific ports and protocols with the datasheet.

- Processing and Memory:

- Processing Power: Features a high-performance processor capable of handling complex monitoring and control tasks. Specific processor details are provided in the datasheet.

- Memory: Includes sufficient memory for data storage and processing. Details on RAM and storage capacity should be confirmed with the datasheet.

- Display and Interface:

- User Interface: May include a local display for configuration and monitoring. The type and size of the display should be specified in the datasheet.

- Software: Compatible with GE’s configuration and monitoring software for detailed analysis and system management.

Functional Features:

- Monitoring Capabilities:

- Parameter Monitoring: Monitors various electrical and mechanical parameters, including voltage, current, frequency, and temperature.

- Real-Time Data: Provides real-time data on system performance and health, enabling immediate response to issues.

- Protection Functions:

- Fault Detection: Detects and responds to electrical faults, such as overcurrent, undervoltage, and short circuits.

- Alarm Management: Configurable alarms and notifications for different fault conditions and system anomalies.

- Automatic Protection: Includes automatic protection features to isolate faults and prevent damage to equipment.

- Control Functions:

- Automated Control: Supports automated control functions based on predefined parameters and conditions.

- Programmable Logic: Allows for programmable logic to customize protection schemes and control strategies.

- Data Logging and Analysis:

- Event Logging: Logs critical events, alarms, and system status for analysis and troubleshooting.

- Historical Data: Provides access to historical data for performance analysis and trend monitoring.

- Integration and Communication:

- Network Integration: Integrates with other control and monitoring systems via standard communication protocols.

- Remote Access: Supports remote access for configuration, monitoring, and diagnostics through network connectivity.

Applications:

- Industrial Processes:

- Condition Monitoring: Used in industrial processes for monitoring and protecting critical equipment and systems.

- Process Control: Facilitates advanced process control by providing real-time data and automated responses.

- Power Generation:

- Generator Monitoring: Monitors and protects generators in power generation facilities.

- Substation Protection: Used in substations for monitoring and protecting electrical distribution equipment.

- Utilities:

- Grid Management: Supports grid management by providing real-time monitoring and control of electrical distribution systems.

- Fault Analysis: Helps in analyzing and responding to faults within utility networks.

- Manufacturing:

- Equipment Protection: Monitors and protects manufacturing equipment to ensure reliable operation and prevent failures.

- Quality Control: Assists in maintaining equipment quality and performance in manufacturing environments.

Additional Information:

- Software Compatibility: Integrates with GE’s VM600 configuration and monitoring software for comprehensive system management.

- Installation: Designed for easy installation with standard mounting options and clear instructions provided in the user manual.

- Certification and Compliance: Adheres to industry standards for safety, performance, and electromagnetic compatibility (EMC). Certification details should be confirmed with the datasheet.