Detailed content

Technical Specifications:

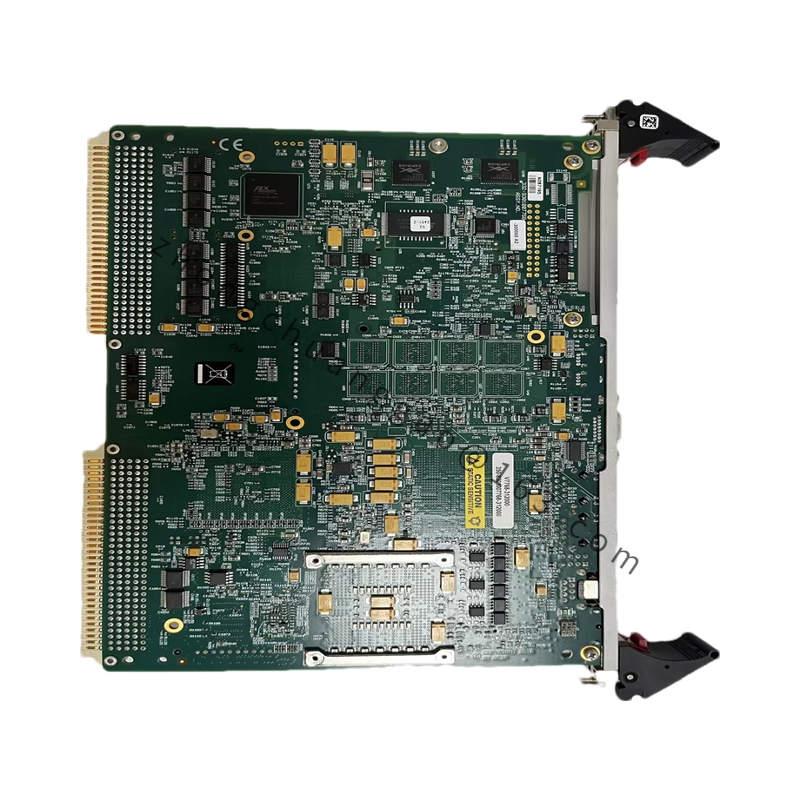

- Model: V7768-312000

- Type: Vibration Sensor / Transmitter

- Power Supply:

- Voltage: Typically operates with a standard power supply, usually within the range of 24V DC. The exact specifications should be verified with the datasheet.

- Measurement Range:

- Vibration Range: The sensor is designed to measure a specific range of vibration frequencies, typically from a few Hz up to several kHz. The exact measurement range should be detailed in the datasheet.

- Output Signals:

- Analog Output: Provides an analog signal proportional to the measured vibration. Common outputs include 4-20 mA or 0-10V. Exact output details should be confirmed with the datasheet.

- Digital Output: Some models may offer digital communication options for integration with control systems.

- Accuracy:

- Measurement Accuracy: Designed for precise vibration measurement, with accuracy details specified in the datasheet.

Functional Features:

- Vibration Measurement:

- Sensor Type: Typically utilizes accelerometer technology to measure vibration levels.

- Frequency Response: Capable of detecting vibrations across a broad frequency range, suitable for monitoring various types of machinery.

- Durability:

- Construction: Built to withstand harsh industrial environments. Features rugged construction for durability and long-term reliability.

- Temperature Range: Operates effectively in a wide temperature range. Specific temperature limits should be confirmed with the datasheet.

- Signal Conditioning:

- Filtering: Includes built-in filtering options to reduce noise and enhance measurement accuracy.

- Calibration: May offer calibration options to ensure accurate and consistent measurements over time.

- Integration:

- Compatibility: Designed to integrate with industrial monitoring and control systems for real-time vibration analysis.

- Mounting: Typically comes with mounting options for easy installation on machinery or equipment.

Applications:

- Industrial Machinery:

- Condition Monitoring: Used for monitoring the condition of industrial machinery to detect early signs of wear or malfunction.

- Preventive Maintenance: Helps in scheduling preventive maintenance activities by providing real-time vibration data.

- Manufacturing Equipment:

- Performance Monitoring: Monitors the performance of manufacturing equipment to ensure smooth operation and minimize downtime.

- Quality Control: Assists in maintaining equipment quality by detecting abnormal vibrations that may affect product quality.

- Power Generation:

- Turbine Monitoring: Used to monitor vibrations in turbines and generators, ensuring reliable operation and preventing failures.

- Transportation:

- Vehicle Systems: Monitors vibrations in transportation vehicles such as trains and trucks to ensure safety and performance.

Additional Information:

- Software Compatibility: May be compatible with various industrial monitoring and control software for enhanced data analysis and visualization.

- Installation: Designed for straightforward installation with clear mounting instructions and options provided in the product manual.

- Certification and Compliance: Adheres to industry standards for safety, performance, and electromagnetic compatibility (EMC). Certification details should be checked with the datasheet.