Detailed content

Technical Specifications

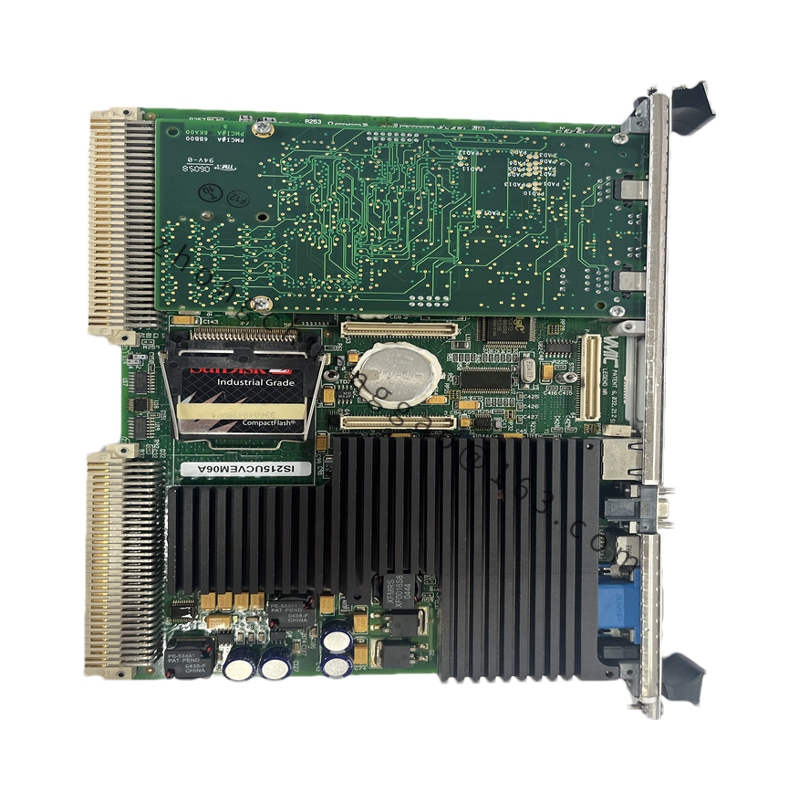

- Brand: GE

- Model: IS215UCVEM06A

- Type: Analog Input Module

- Input Signals: Voltage or Current, representing various physical quantities such as temperature, pressure, and flow

- Channels: Multi-channel, allowing simultaneous monitoring of multiple analog input sources

- Signal Range: Configurable, enabling users to set the input signal range according to application requirements

- Communication Interfaces: Ethernet, Modbus, Profibus, DeviceNet, among others, for data exchange and integration with other automation equipment, control systems, sensors, and actuators

- Power Supply: Typically 220V, but may vary depending on specific configurations

- Protection Rating: High-level protection against dust and moisture, suitable for industrial environments

- Operating Temperature: -40°C to +85°C

- Storage Temperature: -55°C to +95°C

- Size: Approximately 19 cm x 19 cm

- Weight: Approximately 1 kg

- Installation Method: Slide-in installation

Functional Characteristics

- Analog Input Processing: Capable of receiving and processing analog input signals, converting them into digital values for further processing and control

- Multi-Channel Capability: Provides multiple input channels, enabling simultaneous monitoring of various parameters

- Configurable Signal Range: Allows users to set the input signal range, ensuring accurate signal acquisition and measurement

- Communication Flexibility: Equipped with various communication interfaces for seamless integration with other systems

- Real-Time Performance: Responds to input signal changes within milliseconds, ensuring timely data acquisition and control

- Industrial-Grade Design: High reliability, anti-interference, and protection features, suitable for harsh industrial environments

Application Scenarios

- Industrial Automation: Used in controlling and monitoring industrial production processes, including manufacturing, assembly, and packaging

- Process Control: In industries such as chemicals, oil and gas, and pharmaceuticals, it monitors and regulates production process parameters

- Power System Control: Involved in power generation, transmission, and distribution processes, ensuring efficient and safe operation

- Equipment Control: Controls and coordinates various industrial equipment, including motors, valves, pumps, and more

- Data Acquisition and Communication: Collects and transmits device status and data to other systems, facilitating centralized monitoring and management

- Safety Systems: Involved in monitoring and responding to abnormal conditions in equipment or processes, enhancing overall system safety

- Automation System Integration: Integrates different types of equipment and systems into a unified automation control system, improving overall operational efficiency