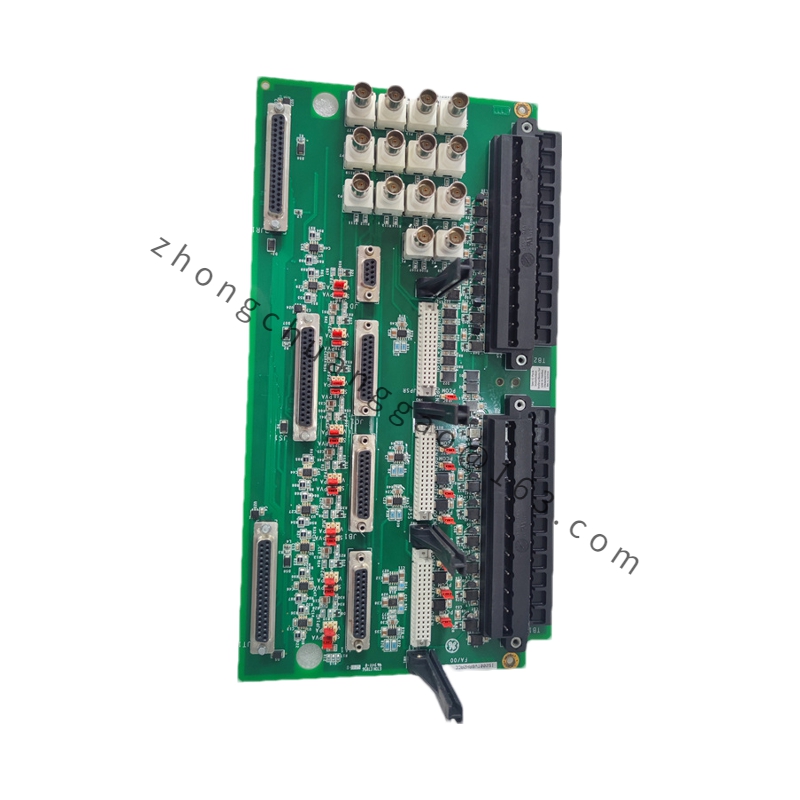

GE IS200TVBAH2ACC

Application Scenarios:

- Industrial Automation and Control Systems: Used widely in industries such as manufacturing, power generation, chemicals, oil and gas, water treatment, and environmental monitoring, where precise control and monitoring of physical parameters are crucial.

- Turbine Equipment Control: Specifically designed for controlling turbine-based machinery, including turbine generators and compressors, in various industrial settings.

- Power Distribution: As a transformer, it finds application in scenarios requiring voltage conversion, such as powering electrical equipment, tools, and machinery that operate on 240VAC.

Detailed content

Technical Specifications:

- Manufacturer: General Electric (GE)

- Model: IS200TVBAH2ACC

- Input Voltage: 120VAC (in cases where it functions as a transformer)

- Output Voltage: 240VAC (as a transformer)

- Power Capacity: 2000 Watts (as a transformer)

- Efficiency: 98% (as a transformer)

- Frequency: 50/60 Hz

- Dimensions: 229 x 127 x 64 mm (9 x 5 x 2.5 inches)

- Weight: 5.4 kg (12 lbs)

Functionality and Features:

-

Multiple Use Cases: Depending on the context, GE IS200TVBAH2ACC can function as a transformer, analog input module, or turbine control module.

- Transformer: Converts 120VAC to 240VAC, commonly used to power equipment requiring higher voltage.

- Analog Input Module: Receives, measures, and processes continuous analog signals such as temperature, pressure, flow, and voltage, essential for industrial automation and control systems.

- Turbine Control Module: Provides high-performance control functions for turbine equipment like turbine generators and compressors, ensuring optimal operation and safety.

-

High-Performance Control: Accurately controls the operational status and performance of turbine equipment.

-

Multiple Input/Output Interfaces: Facilitates connectivity and communication with turbine equipment and other control systems.

-

Real-Time Monitoring and Adjustment: Supports real-time monitoring of turbine equipment status and allows for dynamic adjustment of control parameters.

-

Safety Protection: Incorporates safety features to detect and respond to abnormal operating conditions, ensuring equipment and personnel safety.

-

Flexibility and Configurability: Offers customizable settings to meet various application requirements.

-

Reliability and Stability: Ensures stable operation in harsh environments.

-

Easy Integration: Facilitates seamless integration with existing turbine equipment and control systems.

- Remote Monitoring and Control: Enables remote monitoring and operation of turbine equipment through a network

Application Scenarios:

- Industrial Automation and Control Systems: Used widely in industries such as manufacturing, power generation, chemicals, oil and gas, water treatment, and environmental monitoring, where precise control and monitoring of physical parameters are crucial.

- Turbine Equipment Control: Specifically designed for controlling turbine-based machinery, including turbine generators and compressors, in various industrial settings.

- Power Distribution: As a transformer, it finds application in scenarios requiring voltage conversion, such as powering electrical equipment, tools, and machinery that operate on 240VAC.