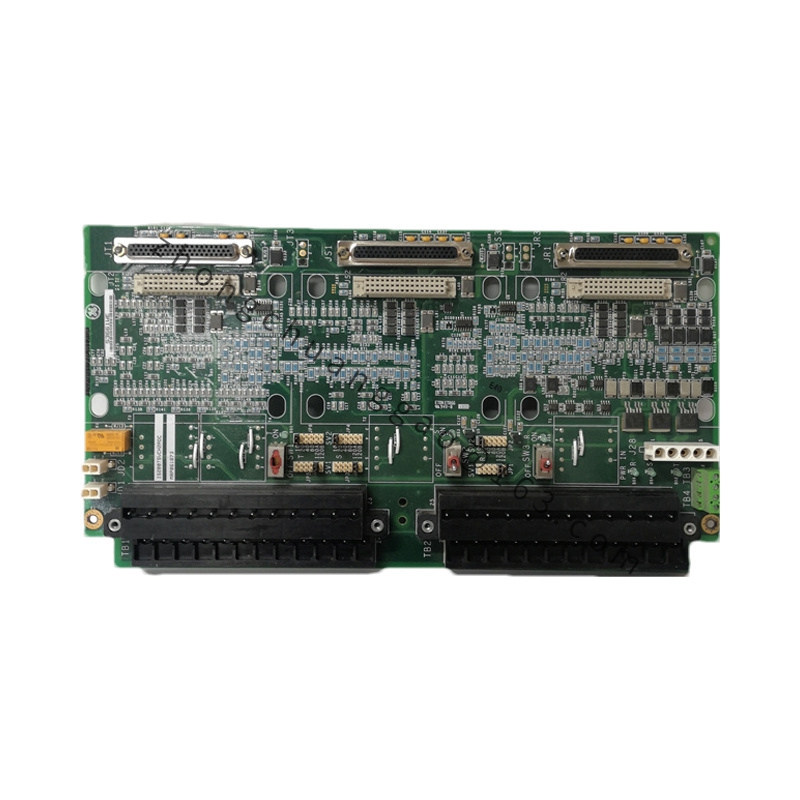

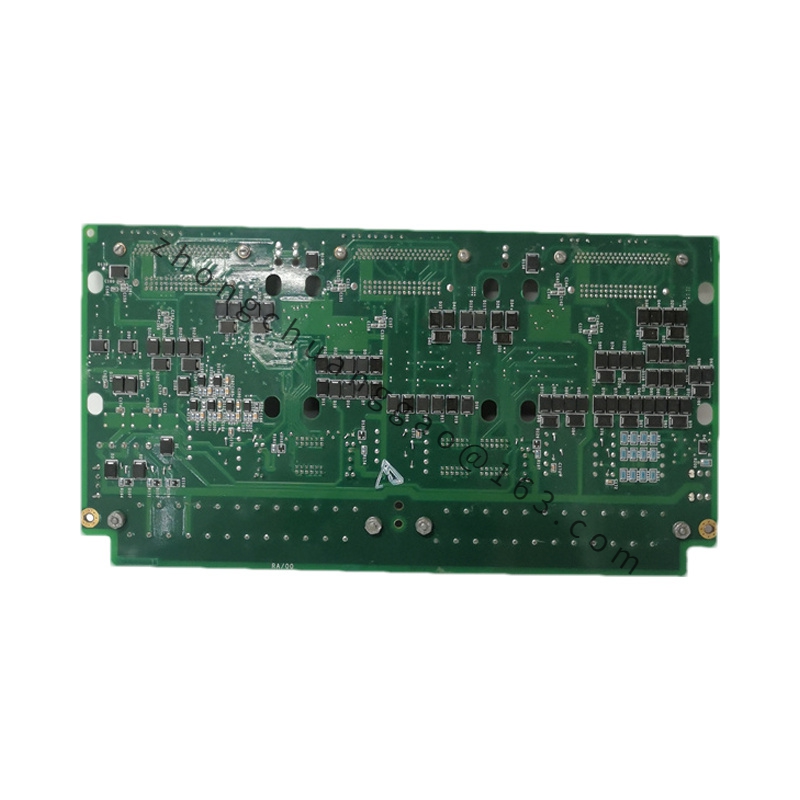

GE IS200TSVCH2ADC MRP061873

The GE IS200TSVCH2ADC MRP061873 is a specialized optical isolation transformer designed to cater to the needs of Opto 22 customers in the energy management market. Below is a comprehensive overview of its technical specifications, functional characteristics, and application scenarios.

Detailed content

Technical Specifications

Temperature Measurement Accuracy:

Resolution: 0.017°C

Accuracy: ±0.8°C

Sensitivity: 1.0 mA/°C

Input Channels:

Eight analog temperature input channels for standard Integrated Circuit Temperature Devices (ICTD)

Up to 128 analog input channels available for various applications

Isolation:

Optical isolation from connected devices and other modules residing on shared I/O racks, preventing electrical interference and fault propagation

Connectivity:

Field device wiring is done through 8-pin connections on two pluggable terminal blocks at the top of the module, facilitating easy installation and maintenance

Functional Characteristics

Multi-Channel Design:

Provides eight dedicated analog temperature input channels and scalability up to 128 channels, making it suitable for both small and large-scale applications

High Precision:

Ensures accuracy and reliability in temperature measurements with precise specifications

Optical Isolation:

Enhances system stability and reliability by isolating the transformer from potential electrical interference

Flexibility and Reliability:

Built upon the 1900 series platform, inheriting the strengths of previous generations while introducing new and enhanced operational features

Remote Communication:

Supports Modbus protocol for remote communication and device interrogation via RS485, with an optional Ethernet connection for integration into larger industrial automation systems

NAMUR-Compliant Relay Function:

Provides relay functionality that allows remote transmission of two concentration alarm levels, maintenance requests, ongoing services, and instrument fault messages

Application Scenarios

The IS200TSVCH2ADC MRP061873 is an ideal choice for a wide range of industrial applications, including but not limited to:

Thermal Forming: Precise temperature control for plastic or metal forming processes

Water Treatment: Monitoring and controlling water temperature in treatment facilities

Refrigeration: Temperature regulation in cold storage and refrigeration systems

Curing: Temperature control during the curing process of materials like concrete or resins

Refining: Temperature monitoring in oil and gas refining processes

PID Loop Control: Closed-loop control systems requiring accurate temperature feedback

Additionally, it can be effectively deployed in OEM applications such as high-pressure sterilizers, HVAC systems, molding machines, and test benches, where cost and space savings are crucial.