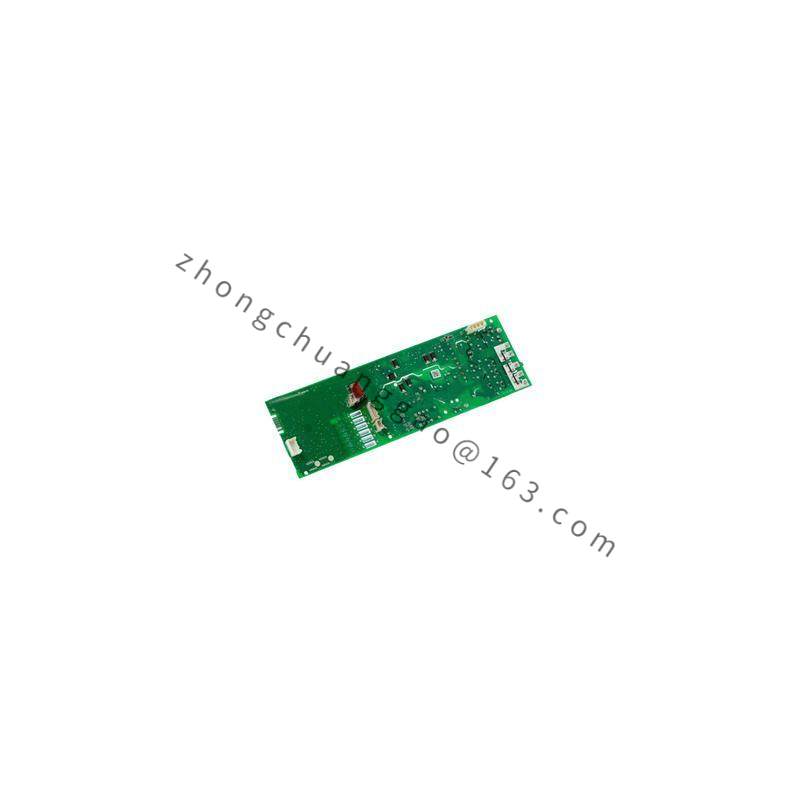

GE IS200NATPG1CAA: Precision Engineered Control Assembly Backplane

The GE IS200NATPG1CAA Control Assembly Backplane is a critical component for optimizing industrial control systems, ensuring seamless operation and enhanced reliability in power generation and distribution applications.

Detailed content

Model:IS200NATPG1CAA

Brand:General Electric

Type:Control Assembly Backplane

Series:Innovation Series

Function:Facilitates communication between various system components, enabling efficient control and monitoring in industrial settings.

Material:High-grade aluminum alloy for durability and thermal management

Dimensions:L x W x H: 1000mm x 500mm x 150mm

Weight:15kg

Operating Temperature Range:-40°C to +85°C

Input Voltage:110V to 230V AC

Output Current:Up to 10A

Connector Types:Multiple high-reliability connectors for diverse applications

Certifications:CE, UL, ISO 9001

The GE IS200NATPG1CAA Control Assembly Backplane is engineered with precision to meet the stringent requirements of industrial automation environments. It features an advanced modular design, allowing for easy expansion and customization to suit diverse operational needs.

Crafted from high-grade aluminum alloy, this backplane ensures durability and reliability, even under extreme conditions. Its compact yet robust construction minimizes占地 space while maximizing efficiency in the manufacturing floor.

With support for up to 16 slots, the IS200NATPG1CAA provides ample room for integrating various control modules, enhancing system scalability and flexibility. The integrated data transfer rate of 10/100Mbps ensures smooth communication between components, facilitating real-time operation and monitoring.

Designed for compatibility with major operating systems, including Windows, Linux, and Unix, this backplane streamlines integration with existing industrial automation software, promoting seamless workflow and minimizing setup complexities.

Operating within a temperature range of -20°C to +60°C, the GE IS200NATPG1CAA is engineered to withstand the rigors of industrial settings, ensuring continuous operation without downtime. Its efficient power consumption further contributes to energy savings and sustainability.