Detailed content

Technical Specifications

- Model:

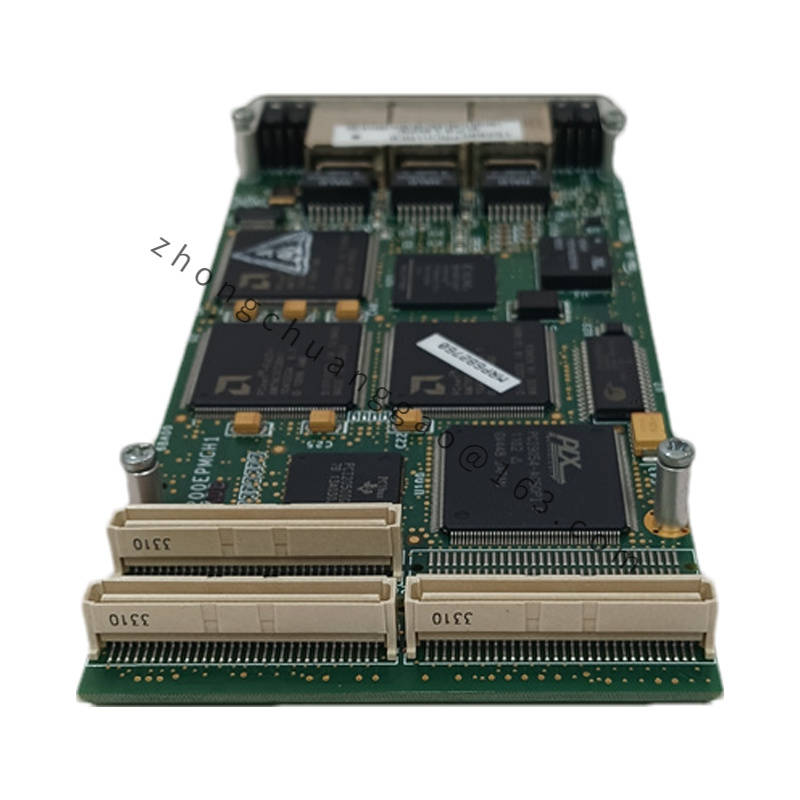

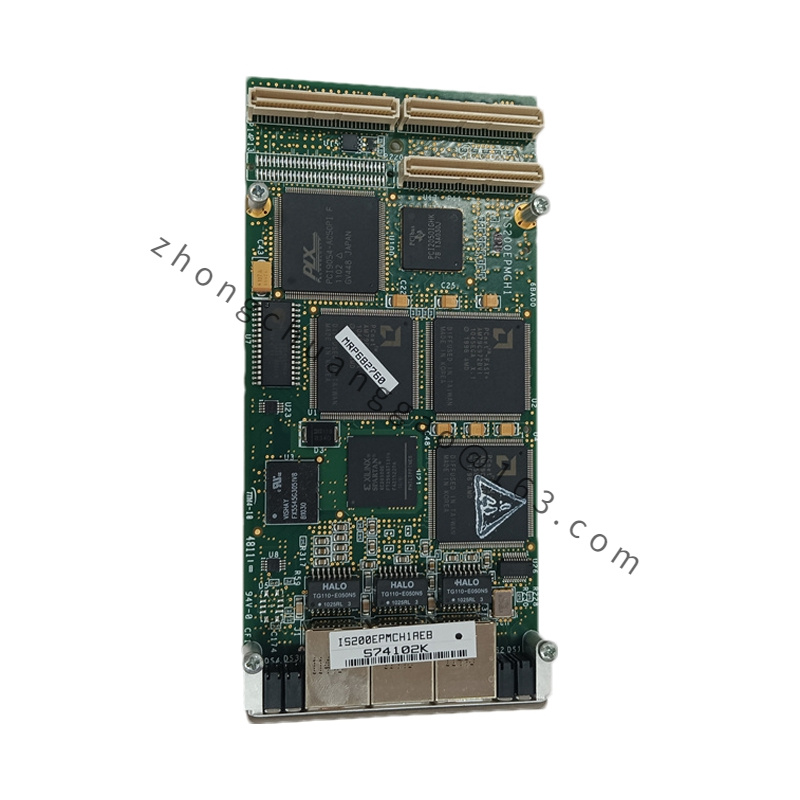

- Model Number: IS200EPMCH1

- Type:

- Category: Digital I/O Module (Part of the Mark VIe control system)

- Processor and Memory:

- Processor: Equipped with a high-performance processor to handle control and communication tasks.

- Memory: Includes memory for storing configuration data and system parameters.

- Input/Output:

- Inputs: Digital inputs for receiving signals from various sensors and field devices.

- Outputs: Digital outputs for controlling actuators and other external devices.

- Power Supply:

- Voltage: Typically operates on a 24V DC power supply, but specific requirements should be confirmed with the manufacturer’s documentation.

- Environmental Conditions:

- Operating Temperature: Designed to function within an industrial temperature range, often from -20°C to +60°C.

- Relative Humidity: Operates effectively in environments with 5% to 95% non-condensing relative humidity.

- Dimensions and Weight:

- Size: Compact design suitable for installation in control panels and industrial racks.

- Weight: Lightweight to facilitate easy installation and handling.

Features

- High-Performance Control:

- Processing Power: Capable of handling complex control algorithms and high-speed data processing.

- Reliability: Designed for high reliability in demanding industrial environments.

- Versatile I/O Capabilities:

- Digital Inputs: Accepts a variety of digital input signals for monitoring purposes.

- Digital Outputs: Provides digital output signals to drive and control external devices and actuators.

- Communication Interfaces:

- Communication Ports: Includes multiple communication interfaces for integration with other system components and networks.

- Protocols: Supports standard industrial communication protocols for seamless data exchange.

- User Interface:

- Configuration Tools: Provides configuration and diagnostic tools for setup and maintenance.

- Monitoring: Allows real-time monitoring of system performance and status.

- Industrial-Grade Design:

- Durability: Built to withstand harsh industrial conditions, including temperature fluctuations, vibrations, and electrical noise.

- Compliance: Meets industry standards for safety and performance.

Applications

- Industrial Automation:

- Usage: Used in industrial automation systems to monitor and control various processes and equipment.

- Application: Suitable for manufacturing, chemical processing, power generation, and other industrial sectors.

- Process Control:

- Role: Functions as a key component in process control systems, ensuring precise control and monitoring of industrial processes.

- Integration: Integrates with other control and monitoring devices for comprehensive process management.

- Data Acquisition:

- Purpose: Collects and processes digital data from field devices, supporting data-driven decision-making.

- Benefits: Enhances system visibility and operational efficiency through accurate data collection.

- SCADA Systems:

- Application: Used in SCADA (Supervisory Control and Data Acquisition) systems for remote monitoring and control of industrial processes.

- Features: Provides real-time data and control capabilities to operators and engineers.

- Building Automation:

- Usage: Applied in building management systems for controlling HVAC, lighting, and other building systems.

- Advantages: Improves building efficiency and occupant comfort through automated control.

Additional Considerations

- Installation and Maintenance: Follow the manufacturer’s installation guidelines for proper setup and ensure regular maintenance to keep the module operating effectively.

- Technical Support: For detailed specifications, configuration assistance, and troubleshooting, refer to GE’s official documentation or contact their technical support team.