Detailed content

Memory:

10 Megabytes (MB) of battery-backed RAM for user memory

10 MB of non-volatile memory (flash memory)

Supports up to 512 program blocks, each with a size of 128 Kilobytes (KB)

I/O Capacity:

Up to 32K discrete inputs and outputs

Up to 32K words of analog inputs and outputs

Communication Interfaces:

Ethernet port supporting 10/100 Mbps data rates with RJ45 physical interface

Three embedded serial ports: RS-232, RS-485, and RS-232 Ethernet Site Manager port

Ethernet port supports automatic negotiation and can be connected to a GPS clock for time synchronization

Physical Characteristics:

Weight: 1.2 kg

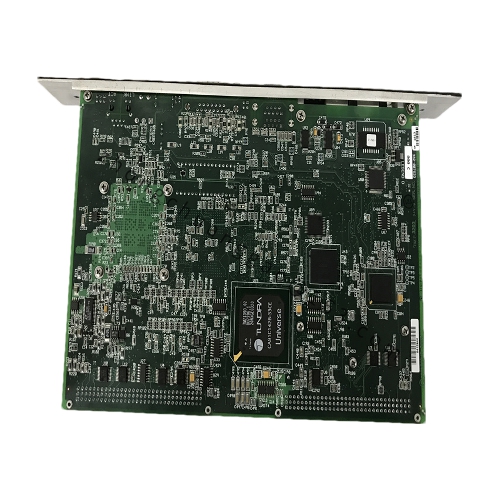

Designed for installation on the VME64 backplane of the RX7i system

Functional Characteristics

Powerful Processing: The 300 MHz Celeron microprocessor enables the IC698CPE010-AA to handle complex control logic and data processing tasks, meeting the high-performance requirements of industrial automation systems.

Versatile Communication: With multiple communication interfaces, including Ethernet and serial ports, the CPU module can seamlessly integrate with other devices and systems, facilitating data exchange and control.

Programming Flexibility: Supports various programming languages such as C, Ladder Diagram (LD), Instruction List (IL), Structured Text (ST), and Function Block Diagram (FBD), allowing users to choose the most suitable language for their applications.

Real-Time Control: Provides real-time control and response, making it suitable for applications requiring high performance and immediate reaction.

Scalability: As part of the RX7i platform, the IC698CPE010-AA can be expanded and upgraded as needed, supporting modular design and integration with various VME-based modules, 90-70 series modules, communication modules, and HMI devices.

Application Scenarios

Industrial Automation: Used in various industrial automation applications, controlling production lines, machinery, and processes.

Process Control: Ideal for monitoring and controlling industrial processes, ensuring smooth and efficient operations.

Energy Management: Deployed in the power industry for power system control and monitoring, including generation, transmission, and distribution.

Pharmaceutical and Chemical: Utilized in the monitoring and control of chemical processes, ensuring production accuracy and consistency.

Water Treatment and Environmental Protection: Used in water treatment facilities to monitor and control water treatment processes, ensuring water quality standards are met.

Transportation Systems: Employed in traffic signal control and intelligent transportation systems, coordinating and optimizing traffic flow.

.jpg)