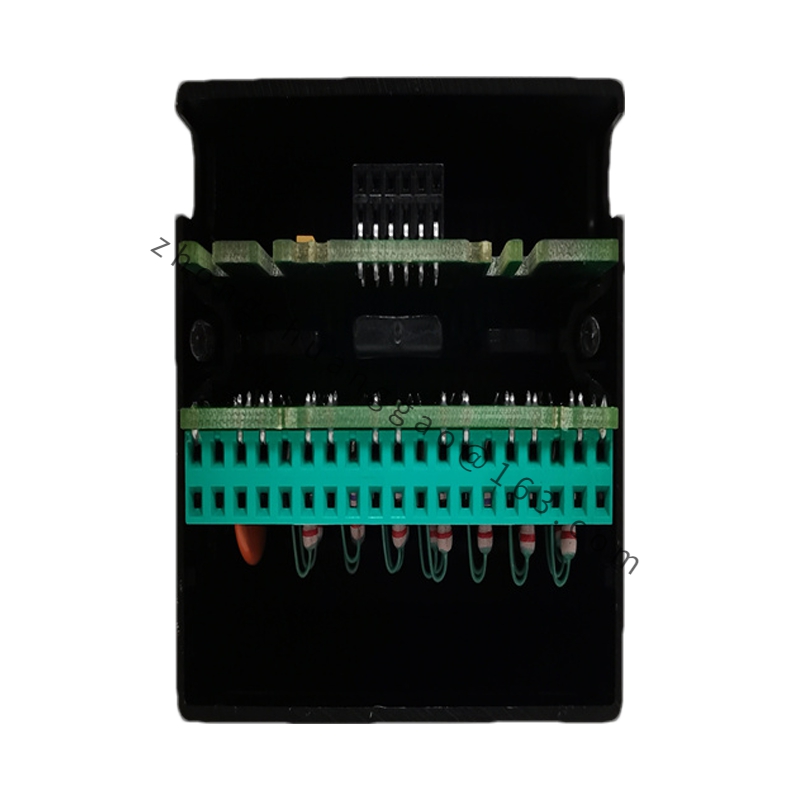

GE IC670MDL640

Compliance and Standards:

- The GE IC670MDL640 is manufactured to meet CE and UL standards, ensuring compliance with international safety and quality requirements.

- Designed specifically for use in standard industrial environments, but not suitable for hazardous locations.

Detailed content

Technical Specifications:

- Input Channels: 16 discrete input channels with positive/negative logic capability

- Input Voltage Range: 0-30 VDC, nominal voltage of 24 VDC

- User Input Current per Point: 7.5 mA

- Power Consumption: 75 mA typical from Bus Interface Unit (BIU) power supply, up to 83 mA maximum with all inputs active

- Logic Ratings:

- Positive Logic:

- Rated ON voltage: +15 VDC to +30 VDC

- Rated OFF voltage: 0 to +5 VDC

- Negative Logic:

- Rated ON voltage: -15 VDC to -30 VDC

- Rated OFF voltage: 0 to -5 VDC

- Positive Logic:

- On-State Current: 3.0 mA to 8 mA

- Off-State Current: Essentially zero

- Response Time: 6 ms typical, 10 ms maximum

- Input Impedance: 3K ohms

- Operating Voltage: Designed for 0 to 30 VDC, with a rated voltage of 24 VDC

Functional Characteristics:

- Versatile Logic Support: Supports both positive and negative logic configurations, allowing for flexibility in different application scenarios.

- Compatibility: Compatible with various programmable logic controllers (PLCs) and is part of the IC670 and IC670MDL series.

- Special Keying Function: The discrete input module supports special keying features, enhancing security and ensuring proper connection.

- Efficient Power Usage: Designed to minimize power consumption, with typical and maximum values clearly defined.

- Fast Response Time: Ensures timely and accurate detection of input signals, critical for many industrial automation applications.

Application Scenarios:

- Industrial Automation: GE IC670MDL640 is an ideal solution for industrial automation systems requiring a high number of discrete inputs.

- Process Control: Used in process control applications where real-time monitoring of multiple input signals is crucial.

- Machine Control: Integrated into machine control systems to detect and respond to various machine statuses and operator inputs.

- Remote Monitoring: Suitable for remote monitoring applications where signals from various sensors need to be captured and transmitted.

- Factory Automation: A vital component in factory automation systems, facilitating the seamless integration of various machines and devices.

.jpg)