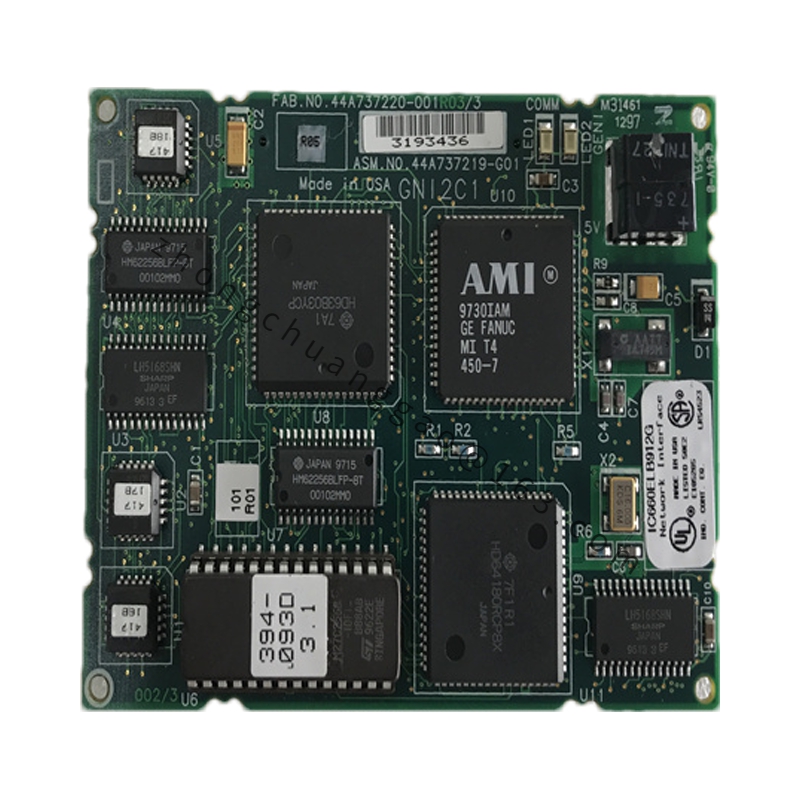

GE IC660ELB912G

Technical Specifications:

I/O Channels: 16 channels, configurable as digital input, digital output, analog input, or analog output.

Digital Input/Output Voltage Range: 24 VDC

Digital Input/Output Current: 5 A

Analog Input Range: 0-10 V or 4-20 mA

Analog Input Resolution: 12-bit

Analog Input Accuracy: ±0.1%

Analog Output Range: 0-10 V or 4-20 mA

Analog Output Accuracy: ±0.1%

Power Supply Voltage: 24 VDC

Operating Temperature Range: -40°C to 70°C

Dimensions: 140mm x 30mm x 25mm

Weight: 200 grams

Enclosure Material: ABS plastic

Connection Type: Terminal block

Detailed content

Functional Characteristics:

High-Speed I/O Response: Provides fast response times for digital and analog signals.

High Reliability: Manufactured with high-quality components and rigorously tested for long-term reliability.

Scalability: Seamlessly connects with other modules in the GE 90-30 PLC series to expand I/O capabilities.

Versatile Configuration: Configurable as digital or analog I/O, offering flexibility in various industrial applications.

Application Scenarios:

Automation Testing: Used in automated test systems for detecting and controlling digital signals.

Data Acquisition and Monitoring: Monitors and records digital input signal states, providing reliable data recording and monitoring capabilities.

Mechanical Control: Controls and monitors the status of mechanical equipment, communicating with sensors and actuators.

Process Control: Controls and monitors digital signals such as switch states and alarm signals in process control applications.

Laboratory Research: Utilized in data acquisition and control applications in laboratory settings, connecting with experimental equipment and sensors.

Industry Applications:

Power: Applicable in power generation and distribution systems.

Oil and Gas: Used in monitoring and control of oil and gas processing facilities.

Chemicals: Suitable for chemical process control and automation.

Water Treatment: Controls and monitors water treatment processes.

Metallurgy: Applied in metallurgical processes for precise control and monitoring.

Pulp and Paper: Utilized in pulp and paper manufacturing processes.

Textiles: Controls machinery and equipment in textile production lines.

Rubber and Plastics: Suitable for automation and control in rubber and plastic processing plants.