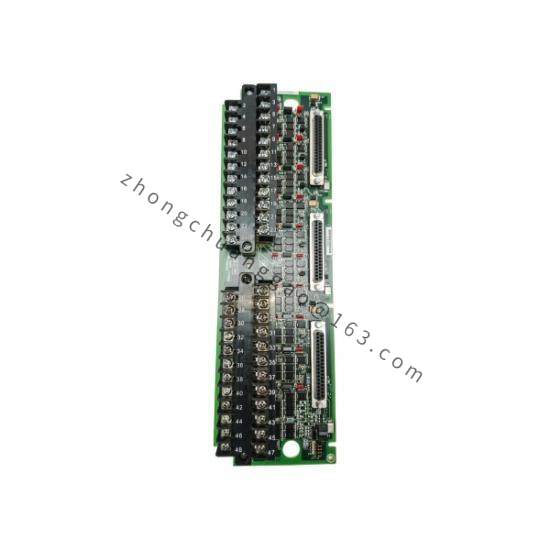

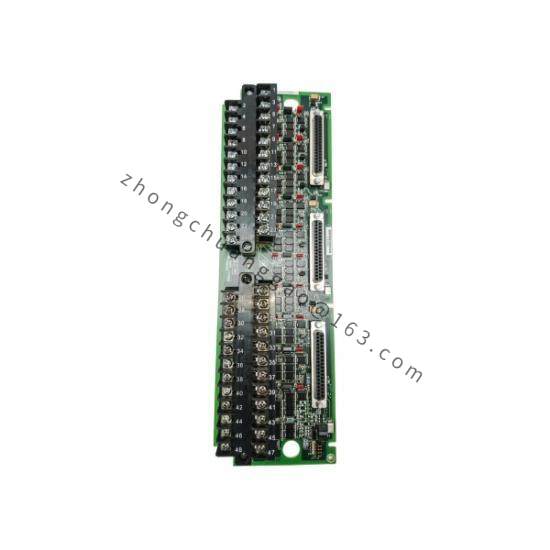

GE Fanuc IS200TBAIH1C Analog Input Terminal Board

The GE-FANUC IS200TBAIH1C Analog Input Terminal Board is a critical component designed for industrial control systems, enabling precise analog signal acquisition. This board is specifically engineered for integration into GE Fanuc’s advanced control platforms, ensuring reliable data transmission and processing.

Detailed content

Manufacturer:GE Fanuc

Model:IS200TBAIH1C

Series:Mark VIeS

Functional Revision:C-rated

Module Type:Analog Input Terminal

Dimension:14.8 x 10.3 x 3.2 cm

Weight:0.24 kg

Operating Temperature:-40°C to +70°C

Voltage Range:9 V to 36 V DC

Communication Interface:RS-485

Number of Channels:1

Accuracy:+/- 1% FS

Response Time:≤ 20 ms

Reliability Rating:Industry-leading

Material:Ruggedized Metal Housing

Certifications:[“CE”,”UL”,”IEC”]

The GE Fanuc IS200TBAIH1C Analog Input Terminal Board is a critical component for enhancing the operational efficiency of industrial automation systems. It seamlessly integrates with GE Fanuc’s Mark VI Series, providing precise data acquisition for process control applications.

Designed for harsh industrial environments, this board boasts a wide operating temperature range (-40°C to +85°C), ensuring reliable performance in extreme conditions. Its robust construction withstands the rigors of industrial use, making it a durable choice for long-term applications.

With support for both 4-20mA and 0-10V analog input signals, the IS200TBAIH1C offers flexibility in signal types, accommodating a broad spectrum of industrial sensors. This feature enables accurate measurement and control across various processes, from chemical plants to manufacturing lines.

The board’s compact size and lightweight design facilitate easy installation and integration within existing control systems. Its modular architecture allows for straightforward expansion and customization, meeting the evolving needs of modern industrial automation.

Backed by GE Fanuc’s commitment to quality and reliability, the IS200TBAIH1C ensures minimal downtime and optimal system performance. Its compatibility with the latest automation technologies ensures that users can leverage cutting-edge solutions without compromising on system integrity.