Detailed content

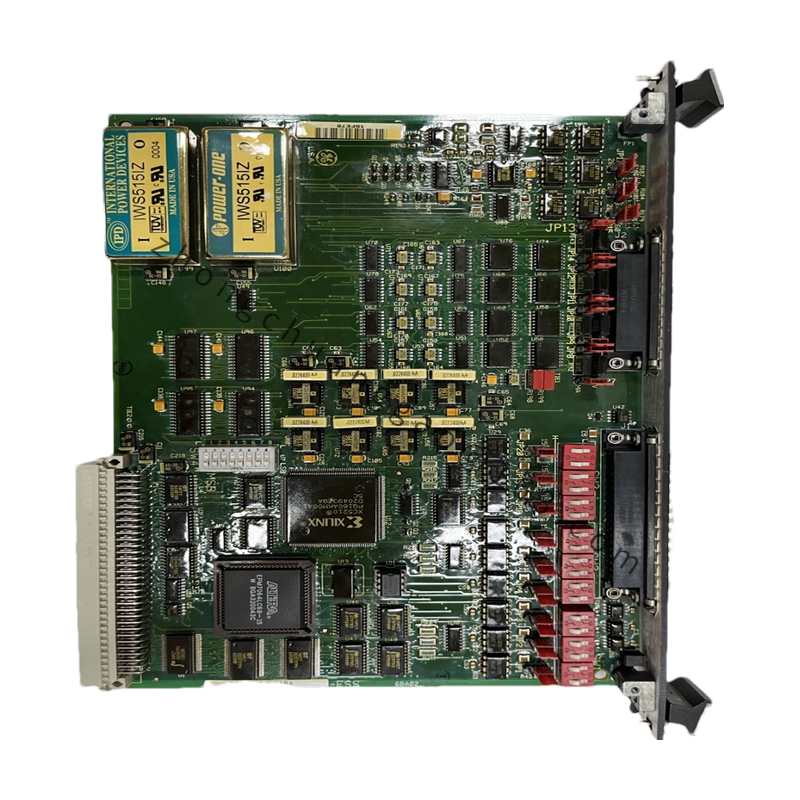

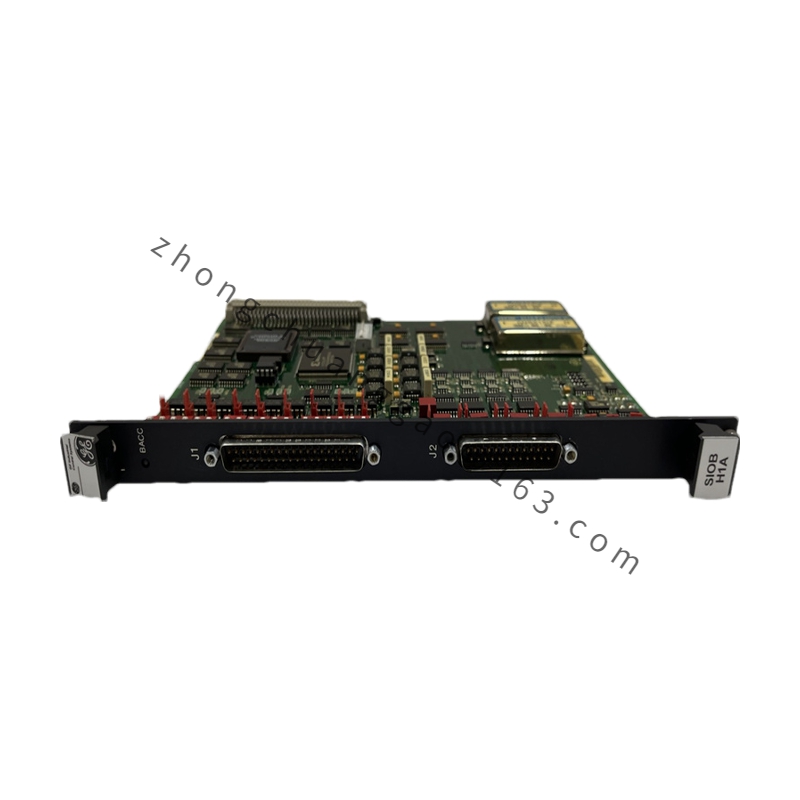

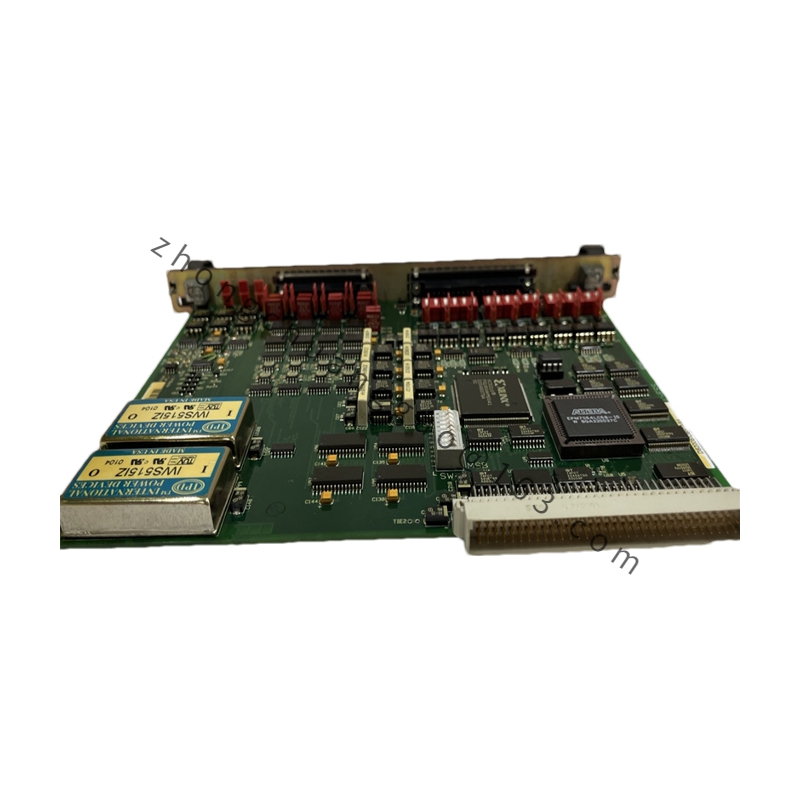

I/O Interfaces Supported:

Digital Input

Digital Output

Analog Input

Communication Interfaces: Supports multiple communication protocols and standards for seamless integration with other devices and systems.

Dimensions (Approximate): 30*20*22 mm (or specified as 5SHX2645L0004mm in some sources)

Current Rating: 5A

Voltage Rating: 220V

Resistance: 5Ω

Functional Characteristics

High Reliability: Manufactured with high-quality materials and undergoing rigorous quality control and testing, ensuring stable operation in harsh industrial environments.

Multiple I/O Interface Support: Provides flexibility to choose from various I/O interfaces, such as digital input, digital output, and analog input, catering to diverse application needs.

Easy Configuration and Maintenance: Offers a user-friendly interface and tools for convenient configuration and debugging. Includes self-diagnostic functionality for rapid fault detection and localization, facilitating maintenance and repairs.

Scalability: Seamlessly connects and integrates with other GE devices, enabling users to expand their systems as needed.

Multiple Communication Interfaces: Supports multiple communication protocols and standards, allowing for seamless communication with other devices and systems.

Application Scenarios

Industrial Automation: Widely used in various industrial automation systems that require precise control and data acquisition.

Process Control: Suitable for process control applications, where real-time monitoring and control of process variables are crucial.

Energy: Applied in energy-related systems for efficient monitoring and control of power generation, transmission, and distribution processes.

Manufacturing: Utilized in manufacturing industries for automated production lines, robotic systems, and other manufacturing processes.

Chemicals: Deployed in chemical processing plants for monitoring and controlling chemical reactions, mixing processes, and other critical operations.

Logistics: Assists in logistics automation, such as warehouse management, material handling, and shipping operations.