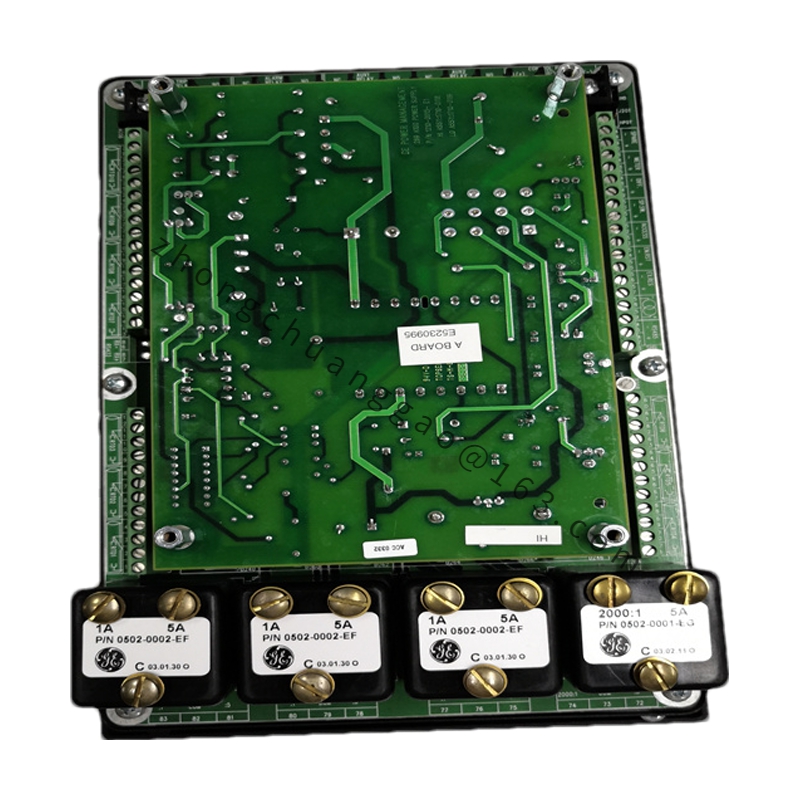

GE 269PLUS-100P-HI

Technical Specifications

Brand: GE

Model: 269PLUS-100P-HI

Type: Control Module

CPU Model: 350 (used as a controller, I/O system, and specialty module)

User Memory: 32KB

I/O Capacity: 4K I/O

Rack Capacity: 8 racks

Logic Execution Speed: 0.22msec/K

Voltage Rating: 120 V AC (as per some sources, but may vary depending on application)

Frequency: 47-63 Hz

Detailed content

Power Consumption: 2.6 W

Weight: 2.8 kg

Dimensions: 12 x 32 x 32 (as per some sources, but may vary)

Communication: Built-in Ethernet supporting SRTP and Modbus TCP/IP

Programming: Supports multiple programming languages such as Ladder Diagram (LDI), Instruction List (IL), Structured Text (ST), and C Blocks

Functional Characteristics

Flexible Industrial Solutions: Designed to meet the demands of flexible industrial solutions.

Scalable Processing Power: Allows users to create an ideal system today with the option to expand in the future without changing software.

Integrated Motion Control: Supports high-performance in point-to-point applications.

Multiple Fieldbus Interfaces: Supports distributed control and/or I/O with various fieldbus interface modules.

Real-Time Link: Provides a real-time link for connected systems through its built-in Ethernet communication.

Compatibility: Compatible with Ethernet, various bus modules, and control modules.

Application Scenarios

Complex Motion Control: Suitable for applications requiring precise and complex motion control.

Mining: Can be used in mining operations for controlling and monitoring various equipment.

Water Treatment: Ideal for water treatment plants, where precise control and monitoring are crucial.

Elevator Control: Suitable for elevator systems, ensuring safe and efficient operation.

High-Speed Packaging: Can be used in high-speed packaging lines for precise timing and control.

Injection Molding: Applicable in injection molding machines for precise temperature and pressure control.

Material Handling: Ideal for material handling systems, such as conveyor belts and robotic arms.

Food Processing: Suitable for food processing plants, where hygiene and precise control are essential.

Continuous Emission Monitoring: Can be used in industries requiring continuous emission monitoring for environmental compliance.

.jpg)