GE 22A-D2P3N104 – Advanced Automation Variable Frequency Drives for Industry 4.0 Solutions

The ABB 22A-D2P3N104 Automation Variable Frequency Drives are engineered for precision control and energy efficiency in industrial applications, offering seamless integration into complex machinery systems.

Detailed content

Brand:General Electric

Model Number:22A-D2P3N104

Drive Type:Variable Frequency Drive

Power Rating:104kW

Operating Voltage:480V AC

Current:65A

Motor Speed Control:PWM

Communication Interface:Ethernet/IP

Network Compatibility:DevNet, Profinet

Protection Class:IP 54

Enclosure Type:Enclosed Cabinet

Control Module:Full Numeric LCD

Braking System:Internal Resistor

Motor Protection:Overload, Overcurrent

Modular Design:Yes

Dimensions:485mm x 485mm x 900mm

Weight:120kg

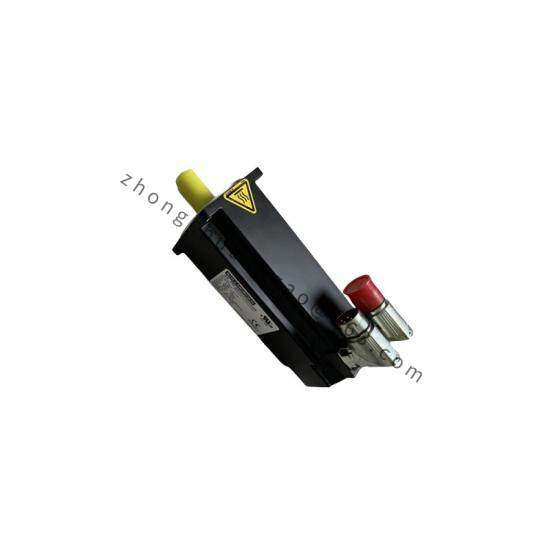

The GE Automation 22A-D2P3N104 Variable Frequency Drive is a testament to cutting-edge technology, designed with precision to handle a wide range of industrial applications efficiently. It seamlessly integrates with modern automation systems, ensuring optimal performance under various operational conditions.

Featuring a compact panel-mount design, this drive minimizes space requirements, making it an ideal solution for retrofitting existing machinery or for new installations where space optimization is crucial. Its robust construction and high-end components ensure durability and reliability, reducing maintenance needs and downtime.

With advanced vector control capabilities, the 22A-D2P3N104 delivers precise speed regulation, enhancing process accuracy and efficiency. Its ability to adapt to changing loads and conditions makes it particularly suitable for processes requiring variable speed control, such as pumps, fans, and conveyor systems.

Equipped with a comprehensive set of safety features, this drive ensures workplace safety by promptly detecting and addressing potential issues like overloads, overcurrent, and short-circuits. This proactive approach minimizes risks and maximizes equipment uptime.

The GE Automation 22A-D2P3N104 is designed with environmental considerations in mind. Its high-efficiency inverter minimizes energy consumption, contributing to sustainable operations and reduced carbon footprints. Additionally, its compliance with industry standards ensures compatibility with a wide range of automation systems and future-proofing for technological advancements.