Detailed content

Technical Specifications

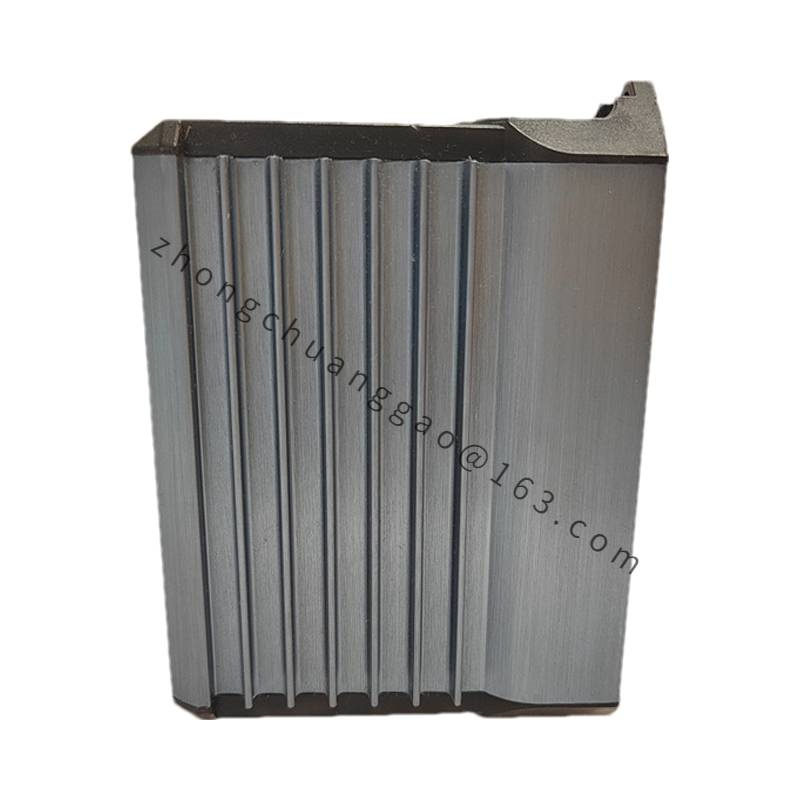

- Model: FBM233

- Type: Fieldbus Module

- System Compatibility: Part of the Foxboro I/A Series DCS.

- Function: Interfaces field devices with the control system using the FOUNDATION Fieldbus protocol. It allows for data communication between the fieldbus network and the DCS.

- Fieldbus Type: Supports FOUNDATION Fieldbus H1, which is commonly used for process automation and control.

- Communication Ports:

- Fieldbus Ports: Provides multiple fieldbus ports for connecting to the FOUNDATION Fieldbus network.

- Backplane Interface: Connects to the DCS system’s backplane for integration with other system components.

- Power Supply: Typically operates on 24V DC or a similar power supply sourced from the DCS system.

- Temperature Range: Operates within standard industrial temperature ranges, usually from 0°C to 60°C (32°F to 140°F).

Features

- Foundation Fieldbus Communication: Facilitates communication with field devices using the FOUNDATION Fieldbus H1 protocol, which supports digital communication and field device integration.

- Integrated Diagnostics: Provides diagnostic capabilities to monitor the health of the fieldbus communication, detect faults, and provide status information for maintenance.

- Real-Time Data Exchange: Supports real-time data exchange between the fieldbus network and the DCS, ensuring timely processing of field data.

- High Integration: Seamlessly integrates with Foxboro’s I/A Series control system, allowing centralized control and monitoring of field devices.

- Configurable: Configurable through Foxboro’s system configuration tools, enabling adaptation to specific application requirements.

- Redundancy: May include options for redundancy to ensure continuous operation and system reliability in case of module or communication failure.

Application Scenarios

- Process Control: Used in various industrial process control applications to interface with and control field devices such as sensors and actuators.

- Manufacturing Automation: Integrates with manufacturing systems to enable reliable communication between field devices and the control system.

- Oil and Gas: Employed in the oil and gas industry for process monitoring and control, including applications such as drilling, refining, and transportation.

- Chemical Processing: Used in chemical plants to interface with process control devices, ensuring accurate control of chemical processes.

- Power Generation: Provides essential communication capabilities for control systems in power plants, managing critical equipment like turbines, boilers, and generators.