Detailed content

Technical Specifications

- Sensor Type: Vibration Sensor

- Model Number: PR6426/010-140

- Measurement Range: Typically used for measuring vibration in machinery, with sensitivity and range suitable for monitoring various types of industrial equipment.

- Frequency Range: The sensor is designed to cover a wide frequency range, making it capable of detecting a broad spectrum of vibration conditions, including low-frequency structural vibrations and high-frequency mechanical faults.

- Output Signal: The sensor outputs an analog signal proportional to the vibration level, which is then processed by the connected module.

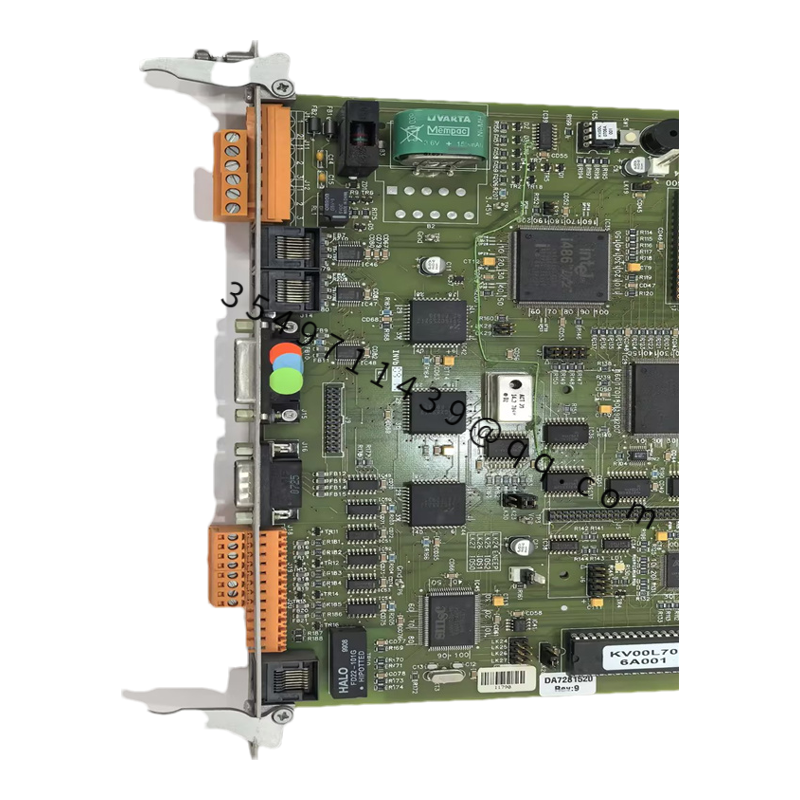

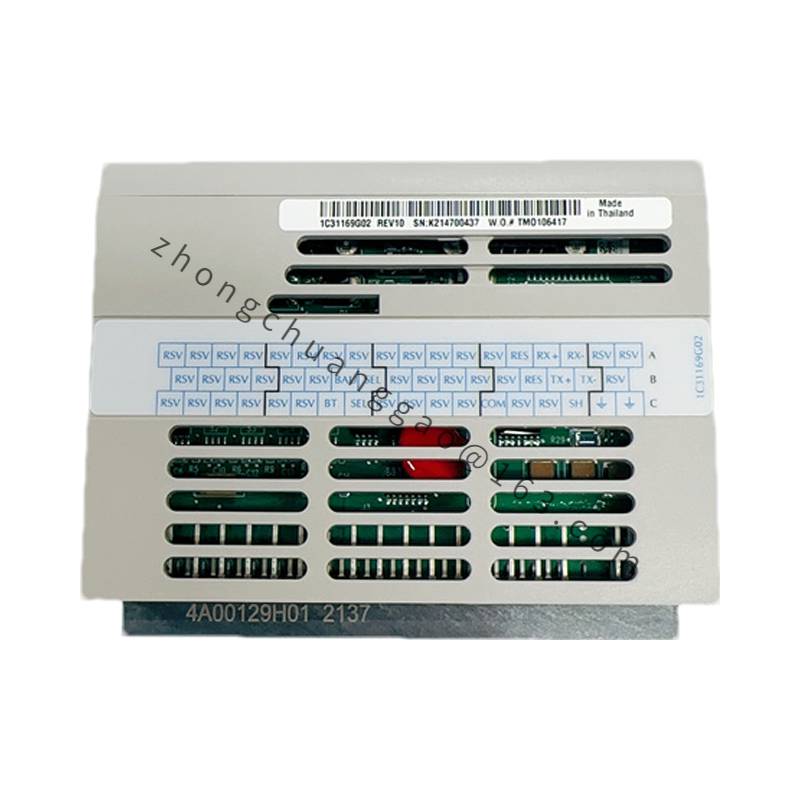

- Connection Module: CON021/916-200

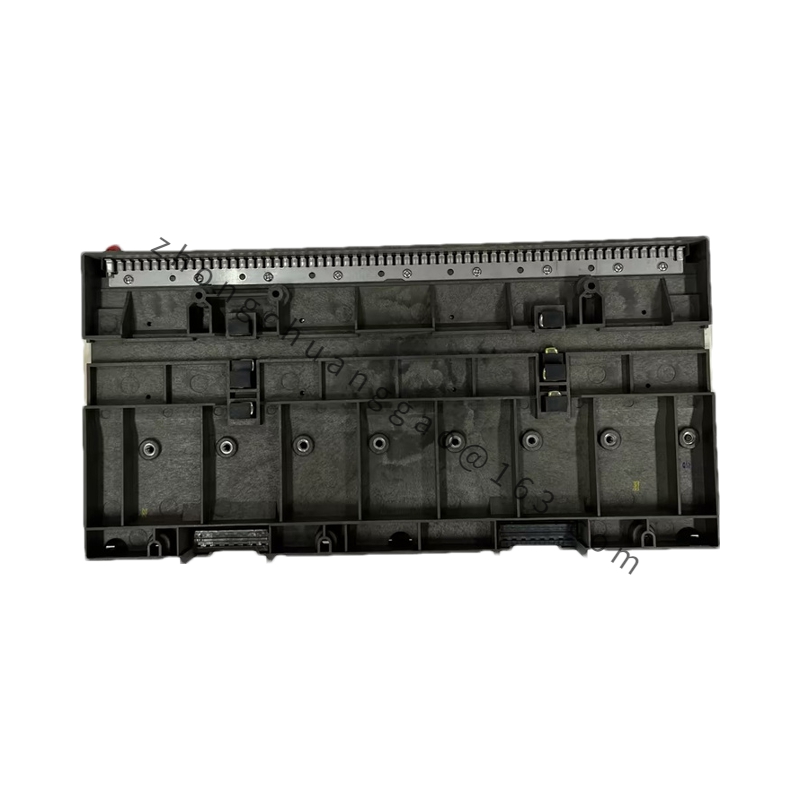

- Interface Type: The CON021 module is used to interface the vibration sensor with the monitoring system. It provides signal conditioning and ensures the integrity of the signal over longer cable runs.

- Power Supply: The module typically requires a low voltage power supply, often in the range of 24V DC, to operate both the sensor and the signal processing circuitry.

- Signal Processing: This module may include basic signal processing features such as filtering and amplification, preparing the signal for analysis by the main monitoring system.

- Connectivity: The CON021 module usually has terminals or connectors to link the sensor output to the condition monitoring system or data acquisition system.

Features

- High Sensitivity: The sensor is designed for high sensitivity, capable of detecting even minor vibrations that could indicate the early stages of machinery failure.

- Robust Construction: Both the sensor and the connecting module are built to withstand harsh industrial environments, including exposure to high temperatures, dust, moisture, and mechanical shocks.

- Versatile Mounting Options: The sensor can be mounted directly on various types of machinery, including motors, pumps, turbines, and compressors, using different mounting options (e.g., studs, adhesives, or magnetic bases).

- Integrated System Compatibility: The PR6426 sensor and CON021 module are designed to integrate seamlessly with Emerson’s condition monitoring systems, such as the CSI 6500, providing a unified platform for machinery health monitoring.

Application Scenarios

- Rotating Machinery Monitoring: Commonly used in industries such as power generation, oil and gas, and manufacturing, where monitoring the health of rotating equipment like turbines, motors, and compressors is critical for operational reliability.

- Predictive Maintenance: The combination of PR6426 and CON021 is ideal for predictive maintenance programs, helping to detect early signs of mechanical wear, imbalance, misalignment, and other issues before they lead to costly downtime.

- Condition Monitoring Systems: Integrated into broader condition monitoring systems, the sensor-module combination helps in continuous online monitoring, enabling real-time decision-making based on machinery health data.

- Safety-Critical Environments: Utilized in environments where equipment failure could lead to hazardous situations, such as chemical plants or refineries, ensuring that machinery operates within safe parameters.