Detailed content

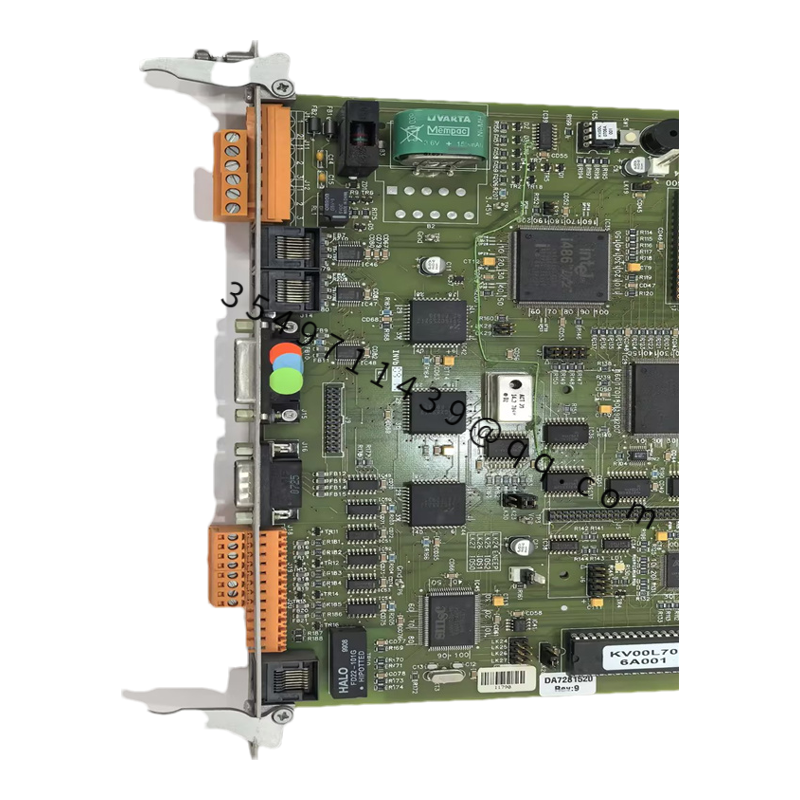

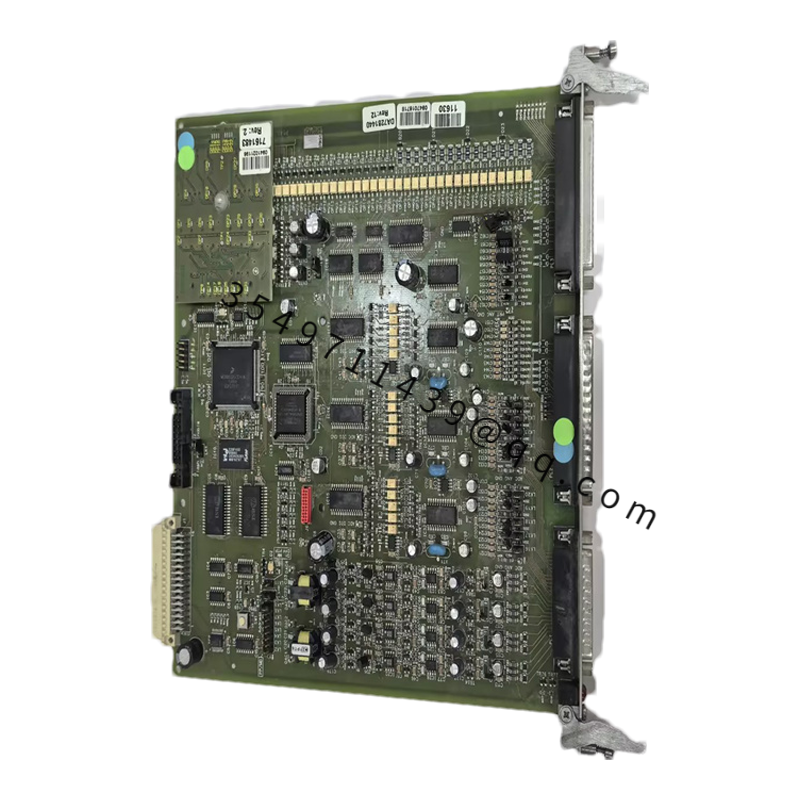

Technical Specifications

- Type:

- Category: Flow Monitor and Data Recorder

- Measurement Range:

- Flow Measurement: Supports a wide range of flow measurement sensors, including electromagnetic and turbine flowmeters.

- Flow Rate Range: Varies based on the connected flowmeter and sensor specifications.

- Input Signals:

- Input Types: Supports various types of input signals including pulse, analog (4-20 mA), and digital signals.

- Channels: Typically accommodates multiple input channels for monitoring different flow meters simultaneously.

- Output Signals:

- Outputs: Provides analog outputs (e.g., 4-20 mA), digital outputs, and alarm signals.

- Communication Interfaces: Includes support for communication protocols such as HART, Modbus, and Profibus for integration with other systems.

- Display and Interface:

- Display: Equipped with a high-resolution LCD display for real-time data visualization and configuration.

- User Interface: Offers a user-friendly interface for configuring settings, viewing data, and performing diagnostics.

- Power Requirements:

- Power Supply: Typically operates on 24V DC; verify with specific model documentation for exact requirements.

- Environmental Conditions:

- Operating Temperature: Usually ranges from -20°C to +60°C.

- Relative Humidity: Operates within 5% to 95% relative humidity (non-condensing).

- Housing:

- Enclosure: Designed for industrial environments with a rugged housing suitable for DIN rail or panel mounting.

Functional Features

- Accurate Flow Measurement:

- Precision: Provides high-accuracy flow measurement and data recording for various types of flow meters.

- Real-Time Monitoring: Offers real-time monitoring and recording of flow data for improved operational oversight.

- Data Recording and Storage:

- Recording: Capable of logging flow data, including historical trends and event logs.

- Storage: Stores significant amounts of historical data for analysis and reporting purposes.

- Alarm and Notification:

- Alarms: Configurable alarms for flow rate deviations, sensor faults, and other critical conditions.

- Notifications: Provides alerts through visual indicators and output signals when alarms are triggered.

- Diagnostic and Maintenance Tools:

- Diagnostics: Includes diagnostic functions to help troubleshoot and resolve issues with flow measurement.

- Maintenance: Facilitates predictive maintenance by providing detailed flow data and trends.

- Integration and Communication:

- Integration: Easily integrates with SCADA systems and other process control systems for comprehensive monitoring and control.

- Communication: Supports multiple communication protocols for data exchange and system integration.

- User-Friendly Operation:

- Configuration: Simplifies setup and configuration through an intuitive interface and menu-driven navigation.

- Ease of Use: Designed for ease of use in both configuration and day-to-day operation.

Application Scenarios

- Industrial Flow Monitoring:

- Usage: Ideal for monitoring flow in various industrial applications such as chemical processing, water treatment, and oil and gas.

- Purpose: Ensures accurate flow measurement and monitoring for process control and optimization.

- Process Control:

- Application: Used in process control systems to manage flow rates and maintain process stability.

- Benefit: Provides accurate flow data to help maintain optimal process conditions and efficiency.

- Energy Management:

- Application: Applied in energy management systems for monitoring and controlling the flow of utilities such as steam and water.

- Advantage: Helps optimize energy use and reduce operational costs by providing detailed flow information.

- Water and Wastewater Management:

- Usage: Employed in water and wastewater treatment facilities to monitor and control flow rates of water and effluents.

- Benefit: Supports effective management of water resources and treatment processes.

- Facility Management:

- Application: Used in building management systems for monitoring and controlling flow in HVAC systems and other utilities.

- Purpose: Enhances facility management by providing real-time flow data and control.

Additional Considerations

- Installation and Calibration: Follow Emerson’s installation guidelines for proper setup and calibration of the FLOBOSS S600.

- Technical Support: For detailed technical documentation, configuration assistance, and troubleshooting, consult Emerson’s official resources or contact their technical support team.