Detailed content

Technical Specifications

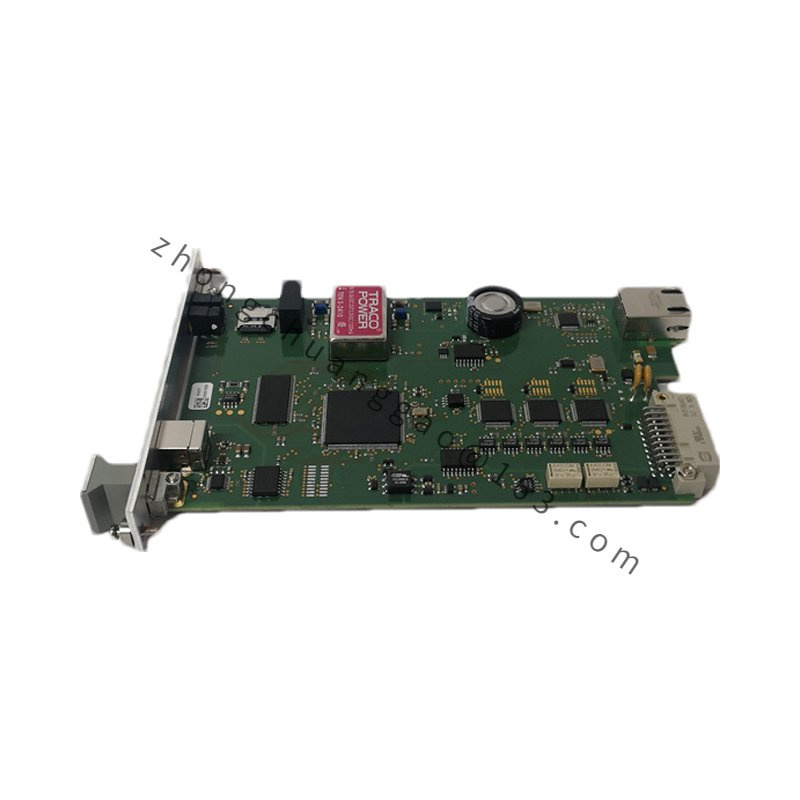

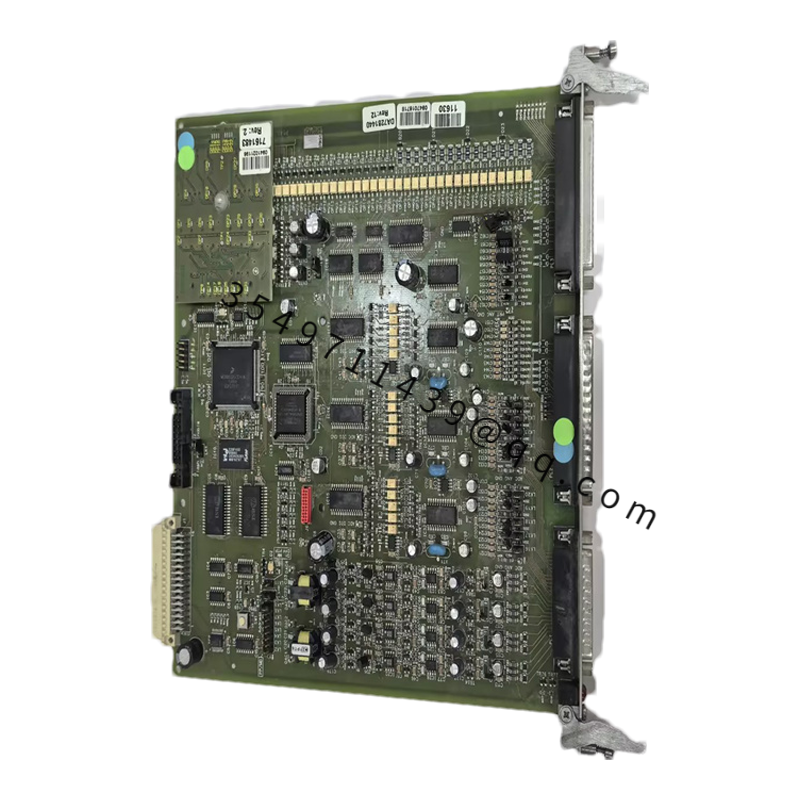

- Type: Machinery Protection System Module (Condition Monitoring)

- Model Number: A6500-CC 9199-00120

- Input:

- Sensor Inputs: The module supports multiple sensor inputs, typically including vibration sensors, temperature sensors, and other transducers used to monitor the condition of rotating machinery.

- Analog Inputs: It features analog input channels to receive signals from various sensors.

- Output:

- Relay Outputs: Includes programmable relay outputs for triggering alarms, shutdowns, or other control actions based on monitored conditions.

- Analog Outputs: May include analog outputs for interfacing with other monitoring systems or control systems.

- Communication:

- Modbus: Supports Modbus communication protocol, allowing for integration with distributed control systems (DCS) or other plant management systems.

- Ethernet: Typically includes an Ethernet port for network communication, facilitating remote monitoring and configuration.

- RS485: Includes RS485 communication for connecting to other modules or systems within the protection system network.

Features

- Vibration Monitoring: Provides advanced vibration monitoring to detect issues such as imbalance, misalignment, bearing wear, and other mechanical faults in rotating equipment.

- Temperature Monitoring: Capable of monitoring temperature to identify overheating issues in critical machinery components.

- Alarming and Shutdown: Configurable alarms and automatic shutdown features help protect equipment by responding quickly to dangerous conditions.

- Data Logging: Includes data logging capabilities for recording historical data, which is essential for trend analysis and predictive maintenance.

- Remote Access: Allows for remote access and monitoring, enabling users to oversee the condition of equipment from a distance, which is particularly useful in large facilities or in multi-site operations.

- System Integration: Designed to integrate seamlessly with other Emerson control and monitoring systems, offering a cohesive solution for plant-wide condition monitoring.

- User Interface: The module typically includes a user-friendly interface for configuration and real-time monitoring, often accessible through a connected computer or control panel.

Application Scenarios

- Rotating Equipment Monitoring: Used extensively in industries such as oil and gas, power generation, and manufacturing, where monitoring the condition of turbines, compressors, pumps, and motors is critical to maintaining operational reliability and safety.

- Predictive Maintenance: The A6500-CC is ideal for predictive maintenance programs, where it helps in early detection of potential failures, allowing for planned maintenance before catastrophic failures occur.

- Industrial Automation: Can be integrated into broader industrial automation systems to provide real-time condition monitoring data, contributing to overall process efficiency and safety.

- Energy Sector: Commonly used in power plants, refineries, and other energy sector facilities where the reliability of rotating machinery is vital to continuous operations.