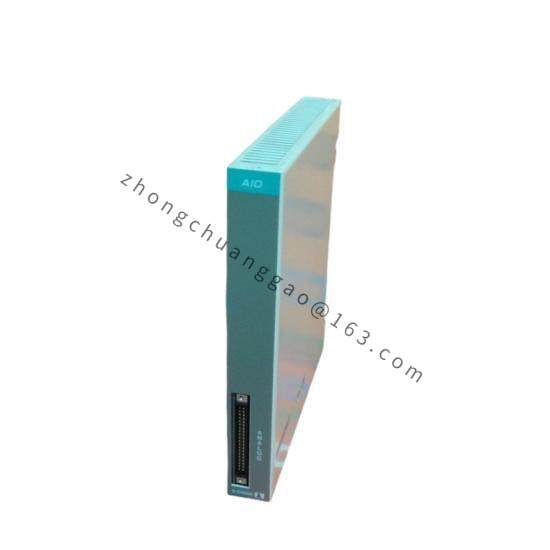

Charmilles 814061B: Advanced Industrial Control Module

The Charmilles 814061B is an advanced industrial control module designed for precision applications in various manufacturing sectors. It ensures high performance and reliability, facilitating seamless integration into complex automation systems.

Detailed content

Operating Voltage:DC 24V

Response Time:≤2ms

Operating Temperature:-20°C to +85°C

Load Capacity:1A @ 24VDC

Communication Interface:RS-485 Modbus RTU

Dimensions:50mm x 40mm x 20mm

Weight:50g

The Charmilles 814061B is a state-of-the-art CNC machining center that combines precision, speed, and versatility to deliver exceptional results for high-end manufacturing tasks. Its robust design and advanced features are tailored to meet the needs of industries requiring extreme accuracy, such as aerospace, medical, and precision tooling.

Equipped with a powerful 30 kW spindle capable of reaching up to 20,000 revolutions per minute, the Charmilles 814061B ensures rapid material removal and maintains high surface finish quality. The machine boasts a compact yet spacious work envelope of 400 x 400 mm in the X and Y axes, and 600 mm in the Z axis, allowing for the processing of large components with ease.

With a tool turret capacity of 24 tools, including options for multi-axis indexing and automatic tool changing, the Charmilles 814061B significantly enhances productivity by minimizing setup times and maximizing the number of operations performed in a single run. The rapid tool change feature reduces cycle times to just 3 seconds, further optimizing production efficiency.

Precision is at the heart of the Charmilles 814061B’s capabilities. Equipped with a linear encoder resolution of 1 micron, the machine ensures unparalleled accuracy in all movements. This level of detail is critical for applications where dimensional tolerances are paramount. Additionally, the machine is equipped with a spindle thermal compensation system, which uses temperature-controlled cooling to maintain consistent performance across a wide range of materials and temperatures.

To enhance flexibility and accommodate diverse manufacturing needs, the Charmilles 814061B comes standard with a versatile coolant system. It supports mist coolant delivery for general machining tasks and implements a 3-axis coolant-on-demand system, which can be selectively applied to specific areas of the workpiece to improve surface finish and tool life. This feature is particularly beneficial when dealing with intricate geometries or challenging materials.