Detailed content

Technical Specifications

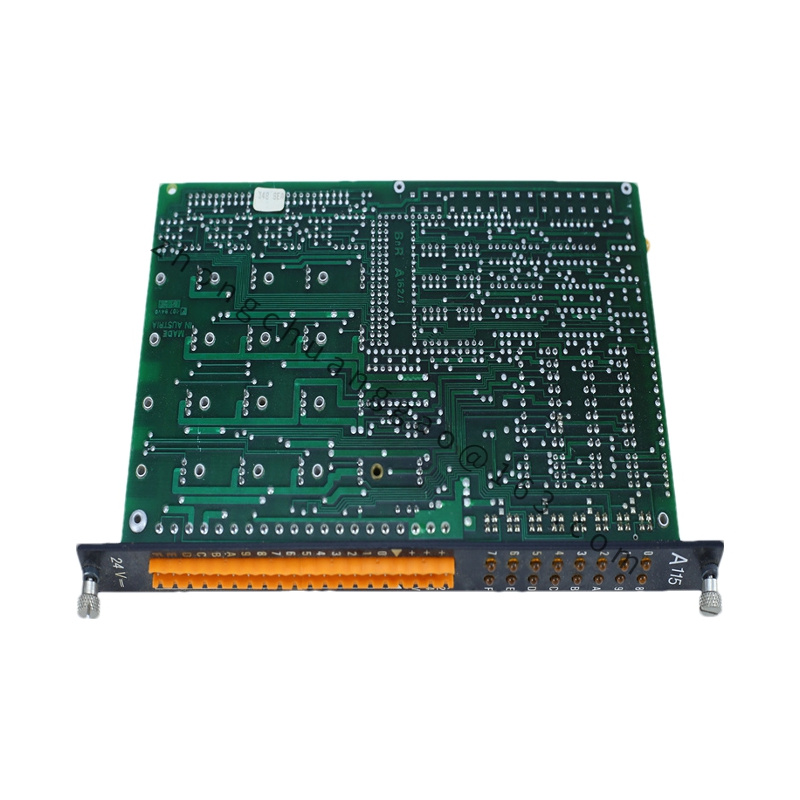

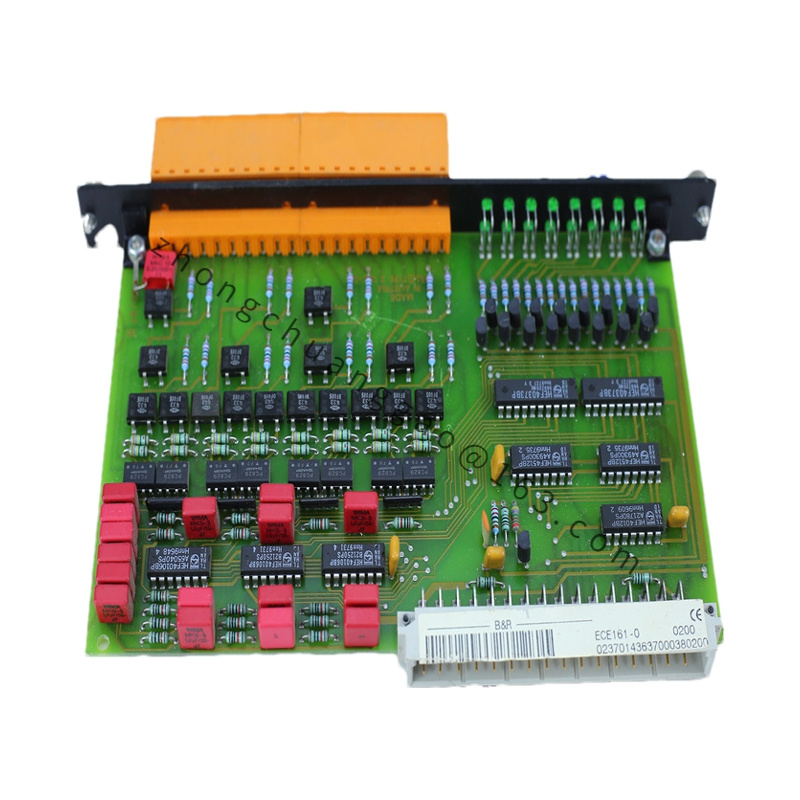

- Model: MDA115-0

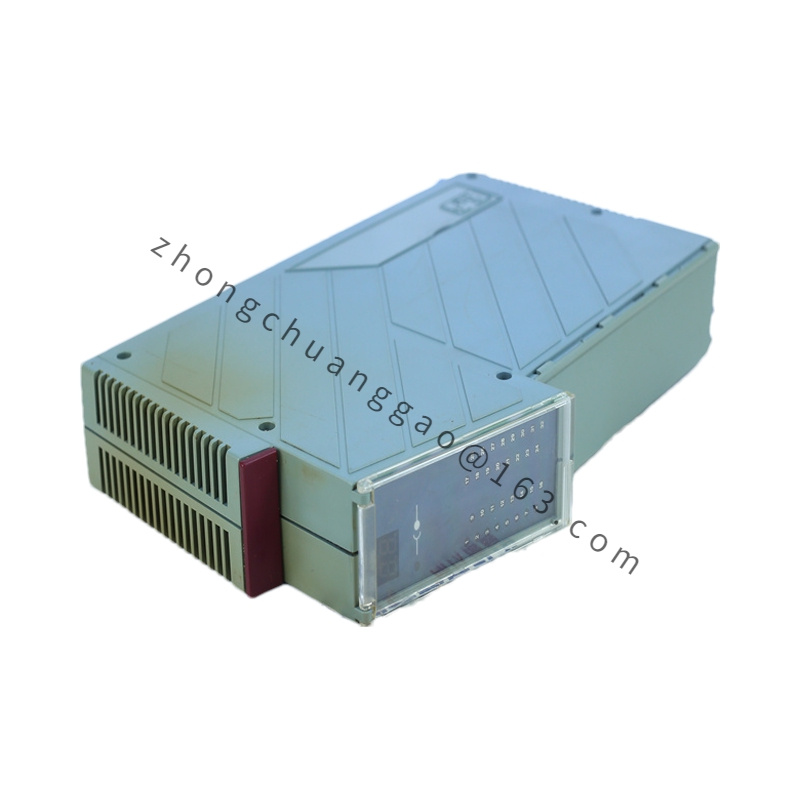

- Type: Motor Drive Module

- Power Supply:

- Voltage: Typically operates with a standard industrial supply voltage, often in the range of 24V DC or other specified ranges based on the exact module configuration.

- Current Rating: Specific current ratings depend on the module configuration and its application.

- Performance:

- Output Power: Output power will vary depending on the application and configuration. For precise details, refer to the product datasheet.

- Control Modes: Supports multiple control modes including velocity control, position control, and torque control.

Features

- Compact Design: The MDA115-0 is designed to be compact, which allows for easy integration into various automation systems and control cabinets.

- High Performance: Provides precise control over motor functions, ensuring smooth and efficient operation in industrial settings.

- Versatility: Capable of controlling a wide range of motors and applications, making it suitable for diverse industrial automation tasks.

- Integrated Diagnostics: Includes diagnostic features for monitoring and troubleshooting, helping to maintain optimal performance and reduce downtime.

- Flexible Connectivity: Supports standard industrial communication protocols, facilitating integration with other B&R automation components and systems.

Application Scenarios

- Industrial Automation: Used in automation systems to control electric motors with high precision, making it ideal for manufacturing and process control applications.

- Machine Tools: Suitable for applications in machine tools where precise motor control is critical for performance and quality.

- Packaging Machinery: Can be used in packaging machinery to control various motor-driven processes.

- Conveyor Systems: Effective in controlling motors within conveyor systems, ensuring smooth operation and synchronization.

Installation and Configuration

- Mounting: Typically installed in control cabinets or on DIN rails, depending on the specific design requirements of the automation system.

- Wiring: Requires standard industrial wiring practices for power and control connections. Detailed wiring diagrams are provided in the product manual.

- Configuration:

- Software Tools: Configuration and programming are generally carried out using B&R’s Automation Studio software, which provides tools for setting up, programming, and monitoring the drive module.

- Parameter Settings: Users can adjust various parameters related to motor control, including acceleration, deceleration, and torque limits, via the configuration software.

Important Notes

- Documentation: For the most detailed and accurate information, including installation instructions, technical specifications, and troubleshooting, consult the official product documentation provided by B&R.

- Compatibility: Ensure compatibility with existing systems and components by referring to the specifications and integration guidelines in the product manual.

- Technical Support: For any specific technical issues or further assistance, contact B&R’s customer support or technical service team.