Detailed content

Technical Specifications

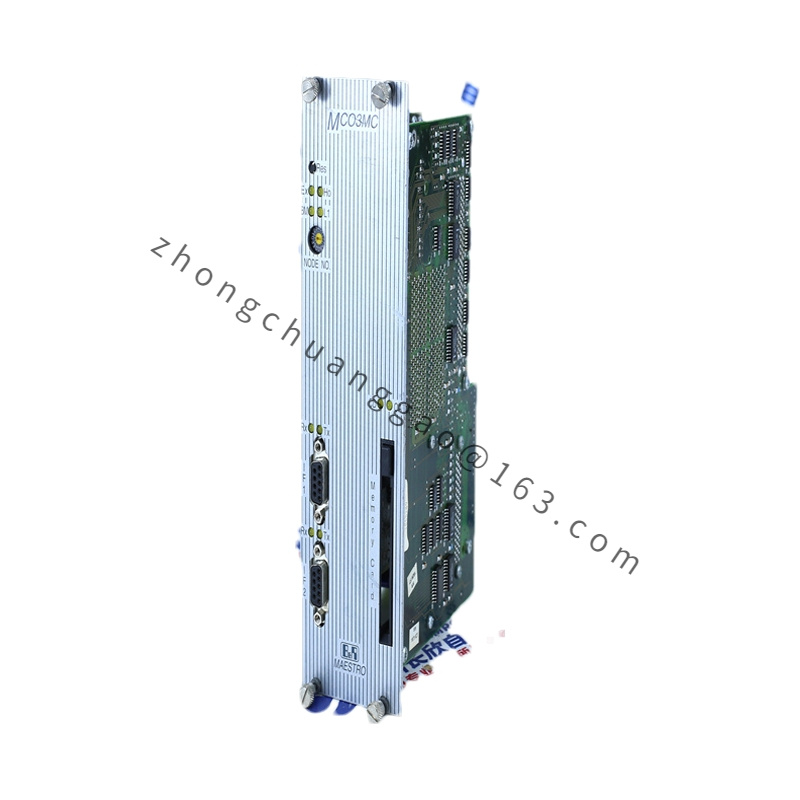

- Model: HCMCO3MC-1A

- Type: I/O Module or Controller Module (Depending on the specific configuration and application)

- Power Supply:

- Voltage: Typically operates on a standard industrial voltage such as 24V DC.

- Communication Interface:

- Ethernet-based Communication: Supports communication protocols such as EtherCAT or other Ethernet-based networks, enabling high-speed and reliable data transfer.

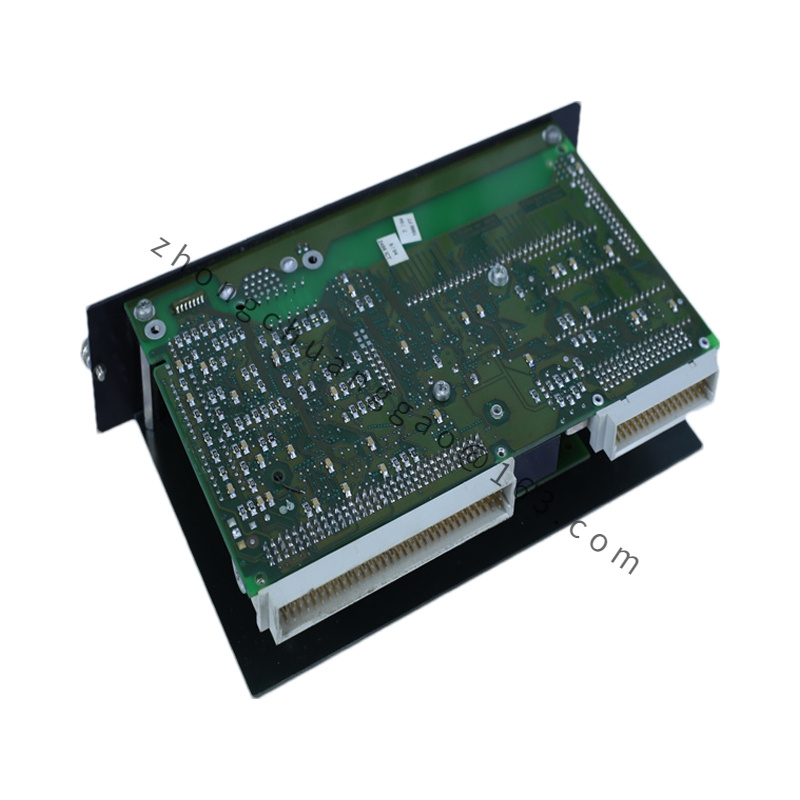

- Dimensions and Mounting:

- Form Factor: Modular design for easy integration into existing automation systems.

- Mounting: Usually DIN rail mounted or panel mounted, based on system requirements.

Features

- Modular Design: Offers flexibility and scalability for different automation needs, allowing integration with B&R’s modular systems.

- Real-Time Data Processing: Capable of handling real-time data for precise control and monitoring, crucial for dynamic industrial environments.

- High Durability: Built to withstand harsh industrial conditions, ensuring reliability and long-term operation.

- Compatibility: Designed to work seamlessly with other B&R automation components and systems, facilitating easy system integration.

- Versatile I/O Capabilities: May include a range of digital and analog I/O options, depending on the configuration.

Application Scenarios

- Industrial Automation: Ideal for use in manufacturing and process automation systems where reliable data acquisition and control are required.

- Machine Control: Suitable for controlling various machinery and equipment, including both small and large-scale operations.

- Energy Management: Useful in systems for monitoring and controlling energy usage and distribution.

- Transport and Logistics: Can be applied in systems for managing and monitoring transport equipment and logistics operations.

Installation and Configuration

- Installation:

- Mounting: Typically installed on a DIN rail or panel mounted, depending on system requirements.

- Wiring: Standard industrial wiring practices should be followed, ensuring proper connection and safety.

- Configuration:

- Software Tools: Configuration and programming are generally done using B&R’s Automation Studio software, which allows for easy setup and management of the module.

- Diagnostics and Monitoring: Provides real-time diagnostics and monitoring capabilities to ensure optimal performance.