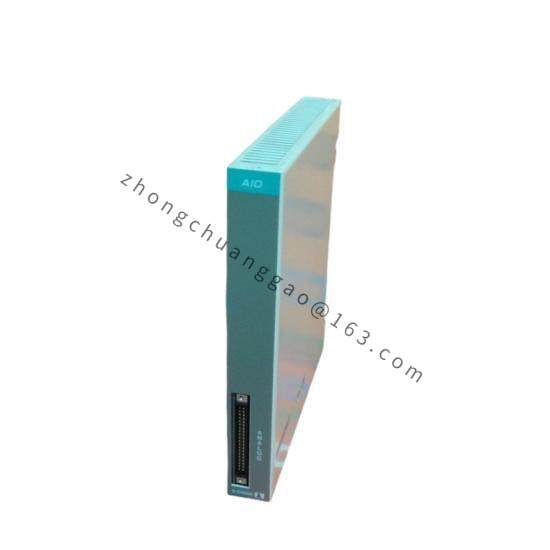

Berthel ComCon 110: Compact, High-Performance PLC Module for Industrial Automation

The Berthel ComCon 110 is an advanced industrial control module designed for seamless integration into complex automation systems. It offers high reliability and robust performance for a wide range of applications in manufacturing, process control, and robotics.

Detailed content

Processor Type:High-performance microcontroller

Memory Size:128 MB RAM, 16 GB Flash

Operating Temperature:-40°C to +85°C

Power Consumption:5 W

Communication Interfaces:RS-232, RS-485, Ethernet

Input/Output Channels:24 input, 16 output

Dimensions:100mm x 100mm x 30mm

Weight:0.3 kg

The Berthel ComCon 110 is engineered with a focus on compactness without compromising performance, making it an ideal choice for space-constrained industrial environments. Its high-speed processing capabilities ensure that even complex automation tasks are executed efficiently and swiftly.

Equipped with ample memory capacity, the ComCon 110 can handle extensive programming requirements, providing users with the flexibility to tailor their automation solutions to meet specific needs. The inclusion of both ladder logic and function block diagram programming languages caters to a wide range of user preferences and expertise levels.

With support for multiple communication interfaces, the module seamlessly integrates with various devices and systems, enhancing connectivity and data exchange within industrial setups. Whether it’s through RS-485 or Ethernet connections, the Berthel ComCon 110 ensures reliable communication and interoperability.

Adaptable to a broad spectrum of operational conditions, this PLC module operates reliably within the temperature range of -20°C to +55°C, ensuring consistent performance regardless of the environment. It is also designed with energy efficiency in mind, consuming only 10 watts, which reduces overall power consumption and costs.

Crafted with durability in mind, the Berthel ComCon 110 boasts an IP20 enclosure rating, safeguarding it against dust and non-hazardous liquids. This feature not only protects the internal components from external elements but also ensures the longevity of the device, making it a robust solution for industrial automation.