Detailed content

Technical Specifications

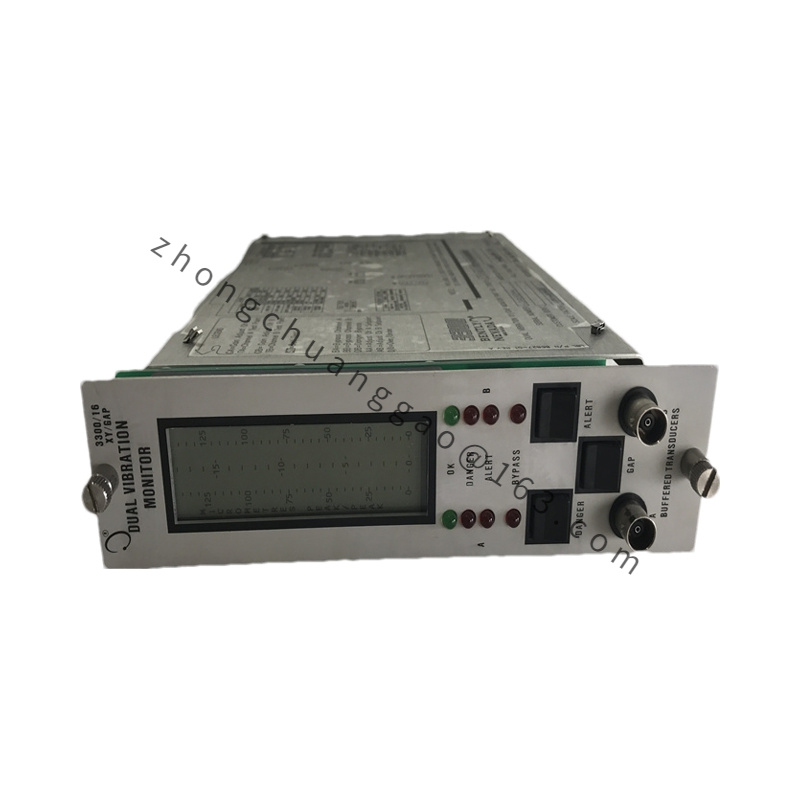

- Model: Bently 330130-080-00-00

- Type: Vibration Sensor (also known as an accelerometer or vibration monitoring sensor)

- Measurement Range: Measures vibration in terms of acceleration, typically in units like g (gravitational acceleration) or m/s². The exact range can vary based on sensor configuration.

- Output Signal: Generally provides an analog output, such as 4-20 mA or 0-10 V, or digital output signals depending on the sensor configuration.

- Sensitivity: Sensitivity refers to the sensor’s response to vibration, commonly expressed in mV/g or mV/(in/s).

- Frequency Response: The frequency range the sensor can accurately measure, which usually spans from low to high frequencies to accommodate various vibration monitoring needs.

- Operating Temperature Range: Typically ranges from -40°C to +85°C (-40°F to +185°F), depending on the sensor’s design and application requirements.

- Protection Rating: Often includes a protection rating like IP67 to guard against dust and water ingress.

Features

- High Precision: Provides accurate vibration measurements to detect even small changes in vibration levels.

- Durability: Designed to withstand harsh industrial environments, offering long-term reliability.

- Stability: Known for high stability and consistent performance over time.

- Compatibility: Compatible with various vibration monitoring systems, facilitating integration into existing setups.

Application Scenarios

- Machinery Monitoring: Used for monitoring the vibration of various machinery such as motors, pumps, and fans to detect potential faults or anomalies.

- Predictive Maintenance: Plays a crucial role in predictive maintenance programs by analyzing vibration data to assess equipment health.

- Industrial Automation: Employed in industrial automation systems to provide real-time monitoring of equipment status, ensuring smooth operation of production lines.

- Power Plants and Oil & Gas: Utilized in critical equipment monitoring in power generation facilities and the oil & gas industry to prevent equipment failures and unplanned downtime.

Usage Considerations

- Installation Position: Proper installation location is essential to obtain accurate vibration data. Ensure that the sensor is installed in a position where it can effectively measure the vibrations of interest.

- Calibration: Regular calibration is necessary to maintain measurement accuracy.

- Maintenance: Periodic checks and maintenance of the sensor are important to ensure its proper functioning and to clean or replace components if needed.

.jpg)