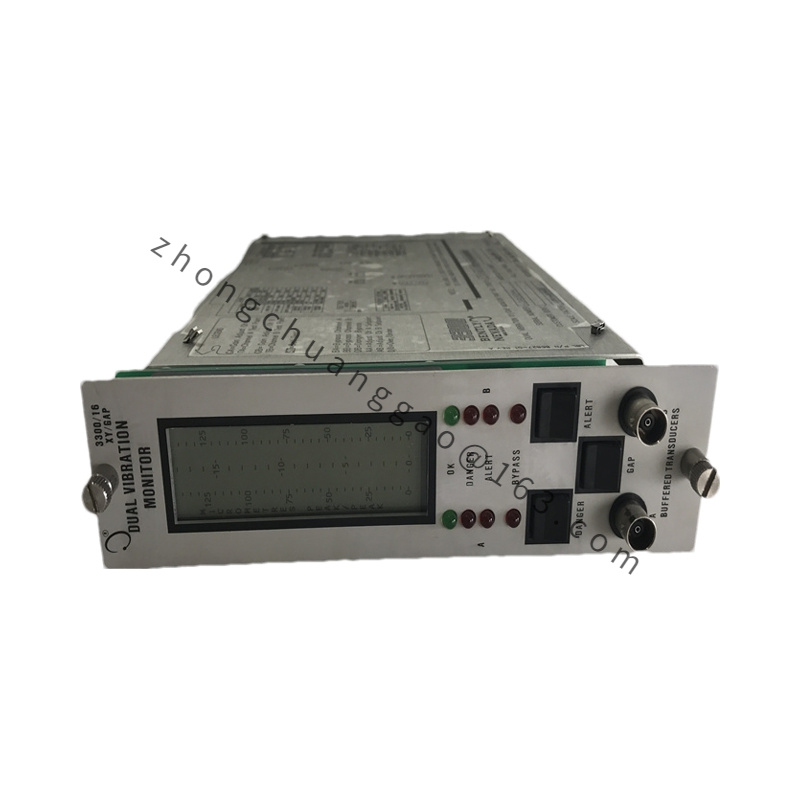

Bently Nevada 990-05-50-01-00 Vibration Transmitter Module

The Bently Nevada 990-05-50-01-00 Vibration Transmitter Modules are designed for precise monitoring and analysis of machinery health, providing real-time data on vibrations to optimize maintenance schedules and enhance operational efficiency in industrial control systems.

Detailed content

Operating Frequency:50 kHz

Material Coding:990-05-50-01-00

Place of Origin:Farley

Output Type:Voltage

Certified Product:Yes

Series:990-05-50-01-00

Module Design:Advanced

Temperature Resistance:High

Termination Type:Gold Connector

Installation Type:Non-contact

Sensing Range:Customizable

Sensitivity:Enhanced

Package/Casing:Injection Molding

This advanced vibration transmitter module is engineered to withstand harsh industrial environments, providing unparalleled accuracy and reliability. It utilizes cutting-edge technology to monitor vibrations within machinery, enabling early detection of potential issues before they escalate into costly failures.

Featuring an injection-molded casing for enhanced durability and a non-contact installation method, this module ensures minimal interference with operational equipment. Its robust design allows it to operate efficiently in temperatures ranging from -40°C to +120°C, making it suitable for a wide array of industrial applications.

With its 50 kHz frequency response and sensitivity of 1 μm, the module offers precise measurement capabilities, essential for predictive maintenance strategies. This precision ensures that maintenance actions are scheduled proactively, reducing downtime and maintenance costs.

Equipped with a gold connector for reliable signal transmission, the module ensures seamless integration with existing monitoring systems. The inclusion of CE and UL certifications guarantees safety and compliance with international standards, further enhancing its credibility in the industrial sector.

Designed for power generation, oil & gas, and chemical processing industries, this vibration transmitter module is a key component in maintaining the reliability and efficiency of critical machinery. Its ability to provide real-time data on machinery health supports informed decision-making, leading to optimized operations and reduced maintenance costs.

.jpg)