Detailed content

Technical Specifications

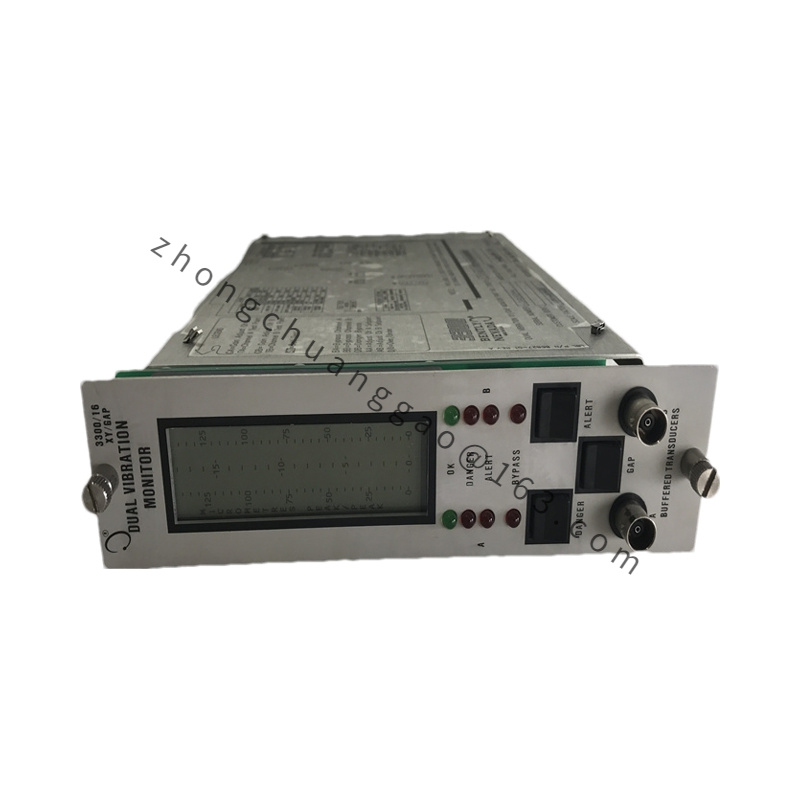

- Model: 350005

- Type: Shaft Vibration Module

- Function: Designed to measure shaft vibration and provide data to monitoring systems for machinery protection and condition assessment.

- Input Specifications:

- Input Type: Compatible with proximity probes and other vibration sensors.

- Number of Channels: Typically, the 350005 module supports multiple channels for simultaneous measurement of shaft vibration.

- Output Specifications:

- Signal Output: Provides processed vibration data to the monitoring system. Outputs are usually designed to integrate seamlessly with Bently Nevada’s 3500 Series system.

- Communication: Communicates with the central monitoring system through standard industrial communication protocols supported by the 3500 Series.

- Environmental Conditions:

- Temperature Range: Operates effectively in industrial environments, typically from -40°C to +85°C (-40°F to +185°F).

- Relative Humidity: Suitable for environments with relative humidity up to 95% (non-condensing).

Features

- High Accuracy: Provides precise measurements of shaft vibration, which is critical for accurate machinery condition monitoring and protection.

- Durable Construction: Built to withstand harsh industrial conditions, including high temperatures, vibrations, and mechanical stress.

- Advanced Signal Processing: Includes sophisticated signal processing capabilities to ensure accurate measurement and interpretation of vibration data.

- Modular Design: Part of the Bently Nevada 3500 Series, allowing for easy integration with other modules and systems for comprehensive machinery monitoring.

- Real-Time Monitoring: Provides real-time data on shaft vibration, enabling prompt detection of potential issues such as misalignment or imbalance.

Application Scenarios

- Machinery Protection: Used in systems designed to protect rotating machinery, such as turbines, generators, and motors, by monitoring shaft vibration and detecting potential issues.

- Condition Monitoring: Essential for continuous monitoring of machinery health, enabling early detection of problems and reducing downtime.

- Industrial Automation: Applied in industrial automation systems where accurate vibration measurement is crucial for maintaining system performance and safety.

- Process Control: Useful in process control environments to ensure stable operation of machinery by providing real-time vibration data and analysis.

Installation and Configuration

- Mounting:

- Form Factor: Typically mounted in a control panel or enclosure as part of the 3500 Series monitoring system.

- Installation: Installation involves connecting the module to proximity probes and integrating it with the central monitoring system. Detailed installation instructions are provided in the product manual.

- Wiring:

- Connections: Connects to vibration sensors and the central monitoring system using standard industrial wiring practices. Wiring diagrams and instructions are included in the product documentation.

- Configuration:

- Calibration: Requires proper calibration to ensure accurate measurements. Calibration procedures are detailed in the product manual.

- Integration: Configure the module within the 3500 Series system for optimal performance and integration with other monitoring components.

.jpg)