Detailed content

Technical Specifications

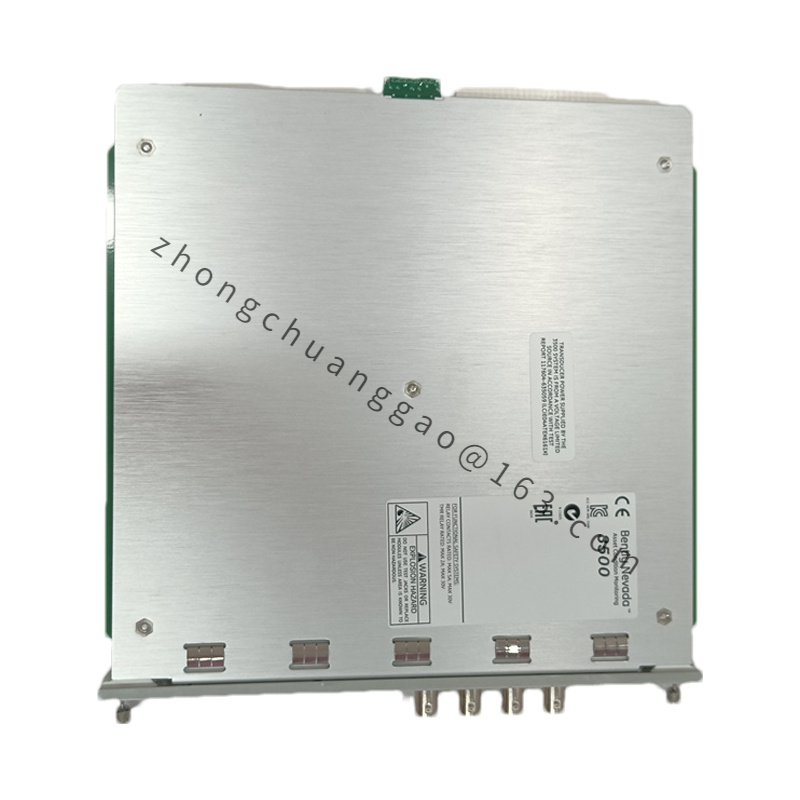

- Type:

- Category: Vibration Monitoring Module

- Measurement Channels:

- Number of Channels: Typically supports up to 4 channels of vibration monitoring.

- Input Type:

- Sensors: Compatible with a range of vibration sensors including accelerometers and velocity sensors.

- Signal Type: Accepts analog signals from various types of vibration sensors.

- Frequency Range:

- Measurement Range: Covers a broad frequency range suitable for monitoring a wide variety of equipment.

- Power Requirements:

- Supply Voltage: Typically requires 24V DC, but specific requirements should be confirmed with the manual.

- Output Signals:

- Outputs: Provides analog outputs, typically 4-20mA, for real-time data monitoring.

- Communication: Supports communication protocols like Modbus or other standard protocols for integration with control systems.

- Environmental Conditions:

- Operating Temperature: Generally operates between -20°C to +60°C.

- Relative Humidity: Designed to work in environments with 5% to 95% relative humidity (non-condensing).

Functional Features

- Real-Time Vibration Monitoring:

- Precision: Provides accurate real-time measurement of vibration levels, crucial for detecting and diagnosing mechanical issues.

- Data Analysis: Capable of advanced analysis such as vibration frequency spectrum to assess equipment condition.

- Alarm and Alert Functions:

- Alarms: Configurable alarms that trigger when vibration exceeds predefined thresholds, alerting operators to potential issues.

- Thresholds: Customizable alarm settings to suit different equipment and operational requirements.

- Diagnostics and Reporting:

- Diagnostics: Offers diagnostic capabilities to assist in identifying and troubleshooting problems with machinery.

- Reporting: Generates reports and trends to aid in predictive maintenance and performance assessment.

- Integration and Compatibility:

- Control Systems: Integrates seamlessly with Bently Nevada’s 3500 Series machinery protection systems and other industrial control systems.

- Compatibility: Designed to be compatible with various vibration sensors and data acquisition systems.

- User Interface:

- Configuration: Configured via a user-friendly interface, typically through the 3500 Series System Manager software or other compatible tools.

Application Scenarios

- Industrial Machinery Monitoring:

- Applications: Used in monitoring the vibration of rotating machinery such as pumps, compressors, turbines, and motors.

- Objective: Aims to prevent unexpected equipment failures by providing early warning signs of potential issues.

- Process Industries:

- Industries: Commonly used in industries such as oil and gas, chemical processing, and power generation.

- Purpose: Ensures the reliability and safety of critical equipment in these sectors.

- Predictive Maintenance:

- Maintenance Strategy: Supports predictive maintenance strategies by providing actionable insights into equipment health.

- Benefits: Helps reduce downtime and maintenance costs through early detection of potential problems.

- Condition Monitoring:

- Monitoring: Employed as part of a broader condition monitoring system to continuously assess machinery performance.

- Advantage: Enhances operational efficiency and reliability by monitoring vibration patterns and trends.

Additional Considerations

- Installation and Maintenance: Follow Bently Nevada’s installation guidelines to ensure proper setup and integration. Regular maintenance and calibration are recommended for optimal performance.

- Technical Support: For further technical details, configuration guidance, and support, consult Bently Nevada’s official documentation or contact their technical support team.