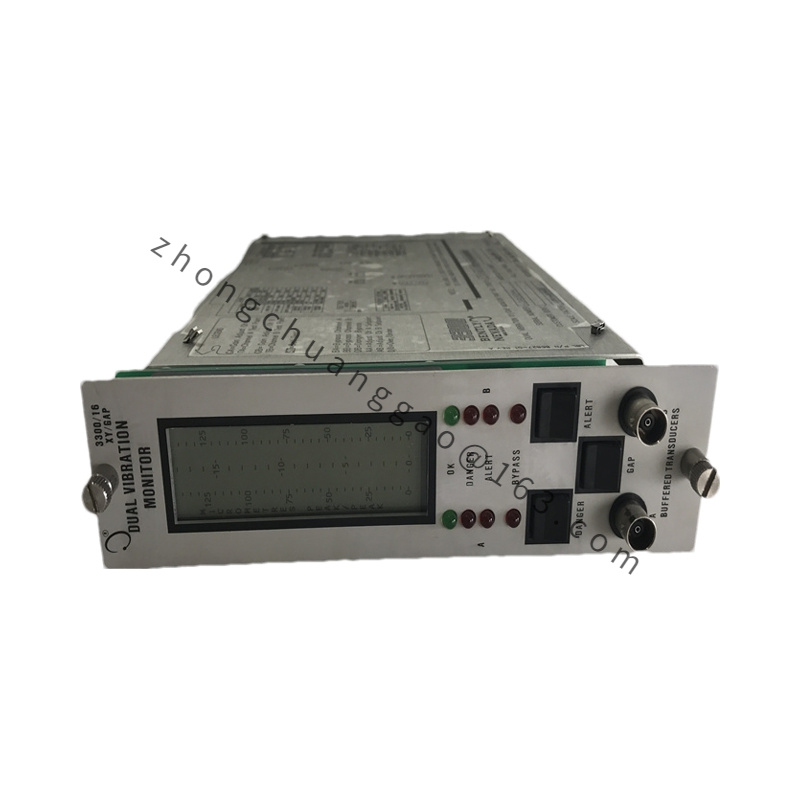

Bently 3500/22M 138607-01

The Bently 3500/22M 138607-01 is part of Bently Nevada’s 3500 Series, which is renowned for its comprehensive machinery protection and condition monitoring solutions. The 3500/22M model is specifically designed for monitoring machinery vibration and temperature to ensure the reliability and efficiency of critical industrial equipment.

Detailed content

Technical Specifications

- Type: Machinery Monitoring System.

- Model: 3500/22M.

- Part Number: 138607-01.

- Inputs:

- Vibration: Accepts inputs from various types of vibration sensors, such as accelerometers.

- Temperature: Can interface with temperature sensors for integrated condition monitoring.

- Measurement Range: Capable of measuring a broad range of vibration frequencies and amplitudes, and temperature ranges.

- Output Type: Provides analog and digital outputs that are compatible with industrial control and monitoring systems.

- Power Supply: Operates on standard industrial power supplies; specific details are provided in the product datasheet.

- Temperature Range: Designed to operate within industrial temperature ranges; details available in datasheet.

- Communication: Features communication interfaces for integration with plant control systems.

Features

- Precision Monitoring: High-precision sensors for accurate measurement of vibration and temperature.

- Integrated Condition Monitoring: Combines vibration and temperature data for a comprehensive view of machinery health.

- Advanced Diagnostics: Offers advanced diagnostic capabilities to identify potential issues early.

- Durability: Designed to operate reliably in harsh industrial environments, including extreme temperatures and mechanical stresses.

- Ease of Integration: Can be easily integrated with existing monitoring and control systems.

Applications

- Machinery Protection: Continuous monitoring of critical machinery to prevent unexpected failures and maintain operational efficiency.

- Condition-Based Maintenance: Supports maintenance strategies based on real-time condition data of the machinery.

- Predictive Maintenance: Helps predict potential machinery failures by analyzing vibration and temperature data, allowing for proactive maintenance.

- Process Optimization: Enhances machinery performance and reliability through detailed condition analysis and diagnostics.