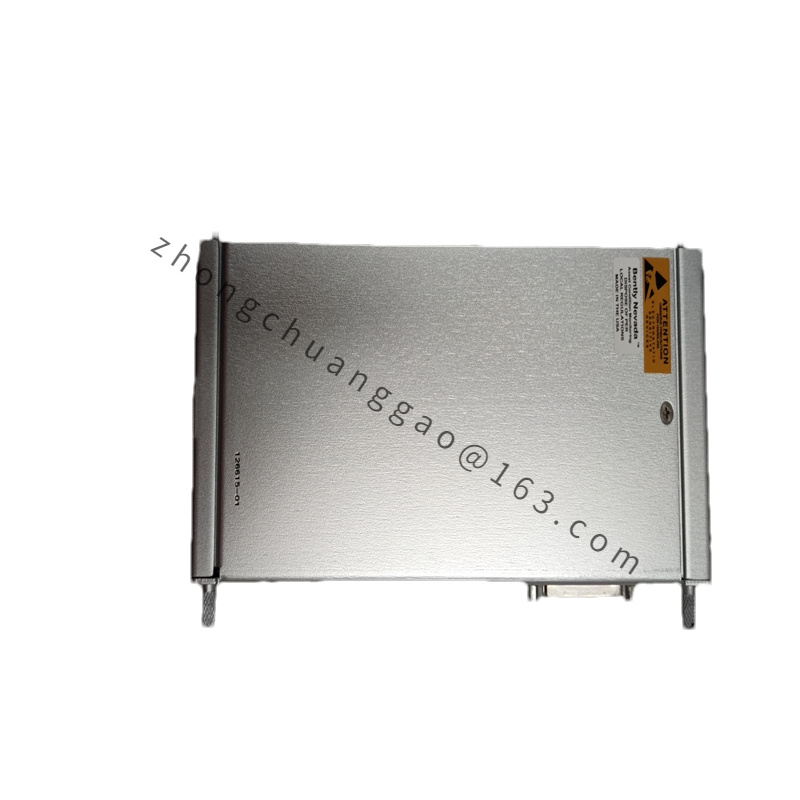

Bently 3300905-00-06-05-02-05

The Bently 3300905-00-06-05-02-05 is a specific model from Bently Nevada’s 3300 Series of vibration monitoring equipment. This model is part of their advanced machinery monitoring solutions designed for high-precision and reliable vibration measurement in industrial environments.

Detailed content

Technical Specifications

- Model: Bently 3300905-00-06-05-02-05

- Type: Vibration Sensor (Accelerometer)

- Measurement Range: The sensor measures vibration acceleration. The specific measurement range is detailed in the datasheet but typically covers a broad spectrum suitable for various industrial applications.

- Output Signal: Provides an analog output, usually a 4-20 mA current loop signal, which is a common output type for industrial vibration monitoring systems.

- Sensitivity: Sensitivity is generally specified in mV/g (millivolts per gravitational acceleration). The exact sensitivity value should be confirmed from the datasheet.

- Frequency Response: Designed to measure a wide range of frequencies, accommodating both low and high frequencies. Detailed frequency response characteristics are provided in the datasheet.

- Operating Temperature Range: Typically operates effectively within a temperature range of -40°C to +85°C (-40°F to +185°F), ensuring reliable performance under various environmental conditions.

- Protection Rating: Usually features a high protection rating, such as IP67, indicating resistance to dust ingress and the ability to withstand temporary immersion in water.

Features

- High Precision: Provides accurate measurement of vibration, essential for detecting minor changes and potential issues in machinery.

- Durable Construction: Built to endure harsh industrial environments, ensuring long-term reliability and performance.

- Stable Operation: Known for stable and consistent performance over time, which is critical for effective monitoring and analysis.

- Ease of Integration: Compatible with a range of vibration monitoring systems, facilitating straightforward integration into existing setups.

Application Scenarios

- Machinery Condition Monitoring: Ideal for monitoring the health of rotating equipment such as motors, pumps, compressors, and turbines. The sensor aids in the early detection of mechanical issues through vibration analysis.

- Predictive Maintenance: Supports predictive maintenance strategies by providing detailed vibration data to forecast potential equipment failures, thereby reducing downtime and maintenance costs.

- Industrial Automation: Used in automated systems for continuous machinery monitoring, ensuring smooth operation and preventing production interruptions.

- Power Generation and Oil & Gas: Applied in critical sectors like power generation and oil & gas to monitor essential equipment, helping to prevent unexpected failures and maintain operational efficiency.

Usage Considerations

- Installation: Proper installation is crucial for accurate measurements. Ensure the sensor is mounted correctly in an optimal position to measure relevant vibrations effectively.

- Calibration: Regular calibration is necessary to maintain the sensor’s accuracy and performance over time.

- Maintenance: Routine inspection and maintenance are important to ensure the sensor remains functional and to address any potential issues promptly.

.jpg)